Method for judging mixed phase mechanism of gas with high content of hydrogen sulfide and carbon dioxide

A technology of carbon dioxide and discriminant method, which is applied in the fields of mining fluid, earthwork drilling, design optimization/simulation, etc. It can solve the problems of less research on dominance, miscibility mode, miscibility pressure, and miscibility process influence mechanism are not clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]In order to illustrate the present invention more clearly, the following further describes the present invention in combination with preferred embodiments. Those skilled in the art should understand that the content described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

[0042]S1. Collect basic data such as the composition of the crude oil from the reservoir and the composition of the injected gas, reservoir temperature and pressure.

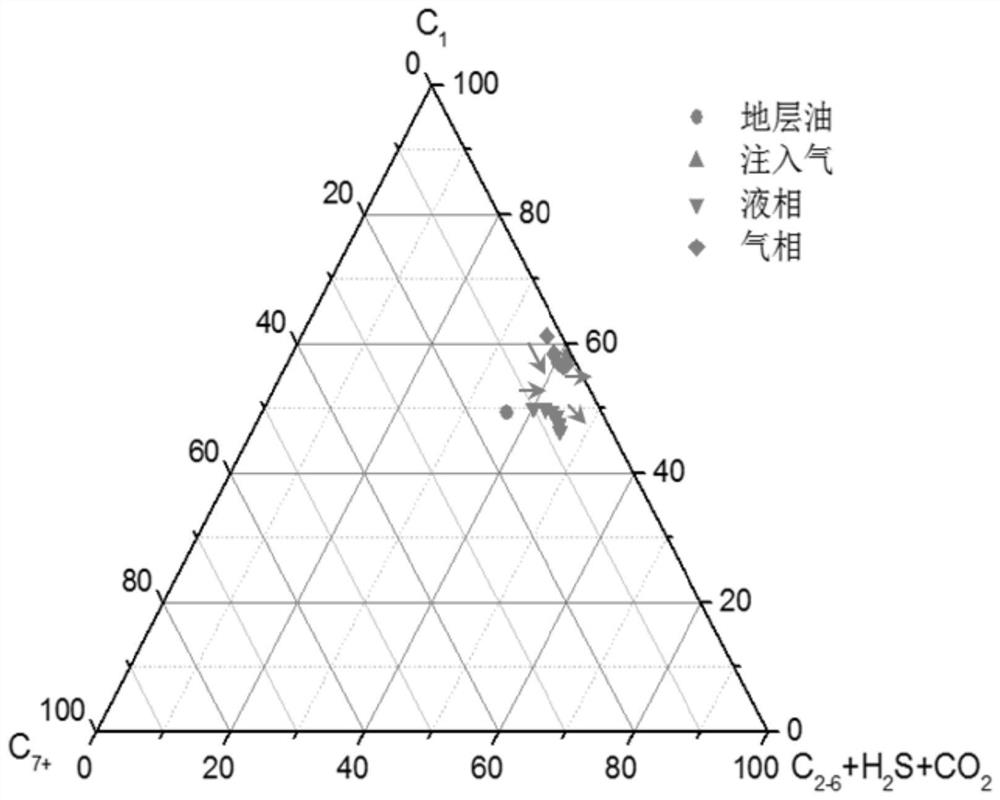

[0043]The composition data of crude oil and injected gas are shown in Table 1:

[0044]Table 1 Composition of crude oil and injected gas

[0045]

[0046]The reservoir temperature is 100°C and the pressure is 77.8MPa.

[0047]S2, note high H2S and CO2Multi-stage gas contact experiment.

[0048]When the oil and gas phase reach equilibrium, the following equation is satisfied:

[0049]fiL= FiV(i=1,2,...n) (1)

[0050]Where: fiLAnd fiVAre the fugacity of component i in the liquid and gas phase respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com