Heat-preservation and energy-saving glass curtain wall

A glass curtain wall and glass plate technology, applied in the direction of heat preservation, parallel glass structures, walls, etc., can solve the problems affecting the integrity and continuity of glass curtain walls, restricting the promotion and popularization of glass curtain walls, wasting labor costs, etc. Noise performance, light weight, and the effect of improving sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

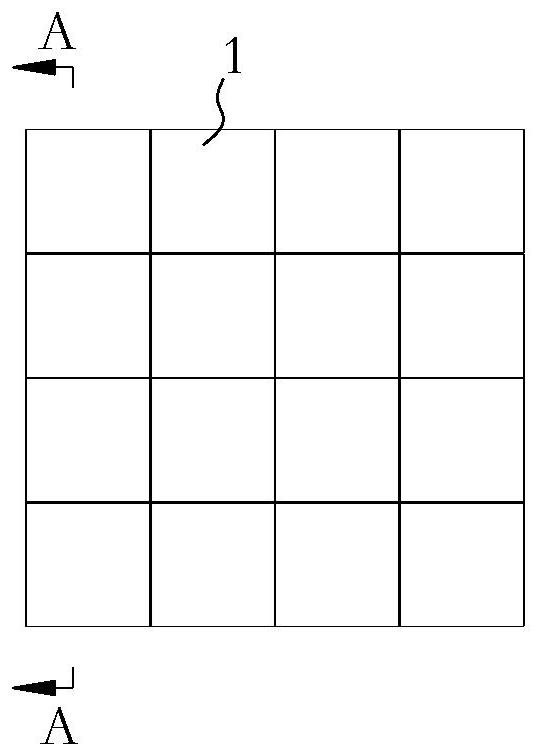

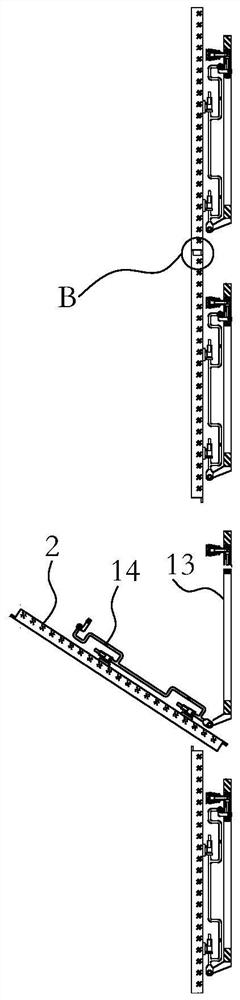

[0032] combine Figure 1-12 The shown glass curtain wall is the same as the traditional glass curtain wall in that the present invention also includes several square curtain wall units 1, and the curtain wall units 1 are installed in a matrix on the keel frame of the building exterior wall, that is to say The glass curtain wall of the present invention is also composed of a plurality of curtain wall units 1, which are also installed on the fixed keel frame on the facade of the building exterior wall. The keel frame is usually made of lightweight high-strength alloy material, which is an existing technology, which will not be repeated here. Compared with the traditional glass curtain wall, the present invention is mainly different in the following aspects:

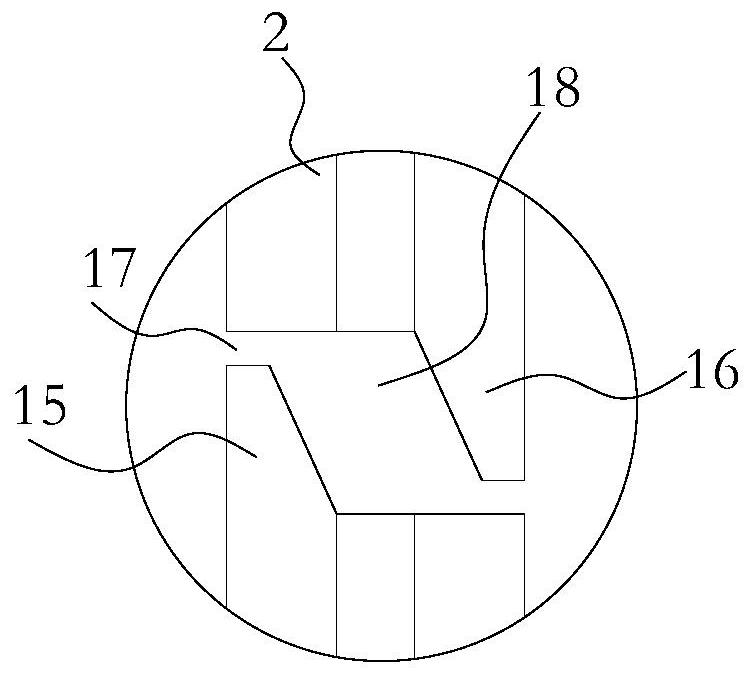

[0033] 1. The structure of the glass plate 2 of the glass curtain wall has a large difference, which changes the structure of the traditional double-glazed or multi-layered glass. Specifically, combined with Figure 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com