Pressure relief device for explosion-proof workshop

A technology for pressure relief and equipment, applied in earthquake-proof, roofing, building and other directions, can solve the problems of high damage limit, factory damage, unsafe explosion-venting equipment and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

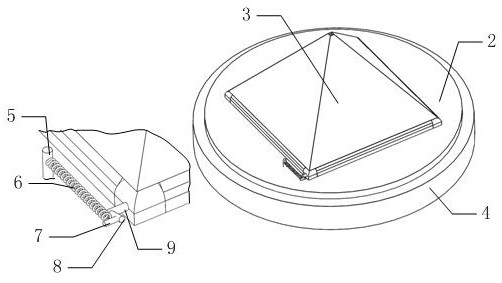

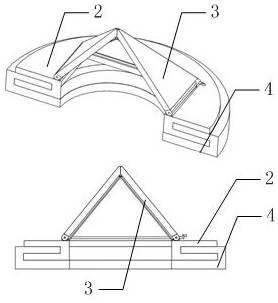

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

[0035] It includes multiple groups of pressure relief modules installed on the roof.

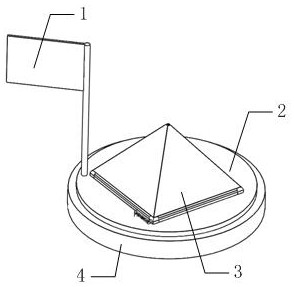

[0036] Such as figure 1 As shown, the above-mentioned pressure relief module includes a swing sensing structure 1 and a pressure relief unit 3 , wherein the swing sensing structure 1 that can swing with the wind direction is installed on the upper side of the pressure relief unit 3 .

[0037] A plurality of such pressure relief modules are evenly placed on the roof of the factory building.

[0038] In the present invention, the swing induction structure 1 is composed of a swing structure that can swing with the wind direction and a connecting rod. The connecting rod is fixed on the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com