Metal recovery device

A recovery device and metal technology, applied in solid separation, filter screen, grid, etc., can solve the problems of waste, labor-intensive, small size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

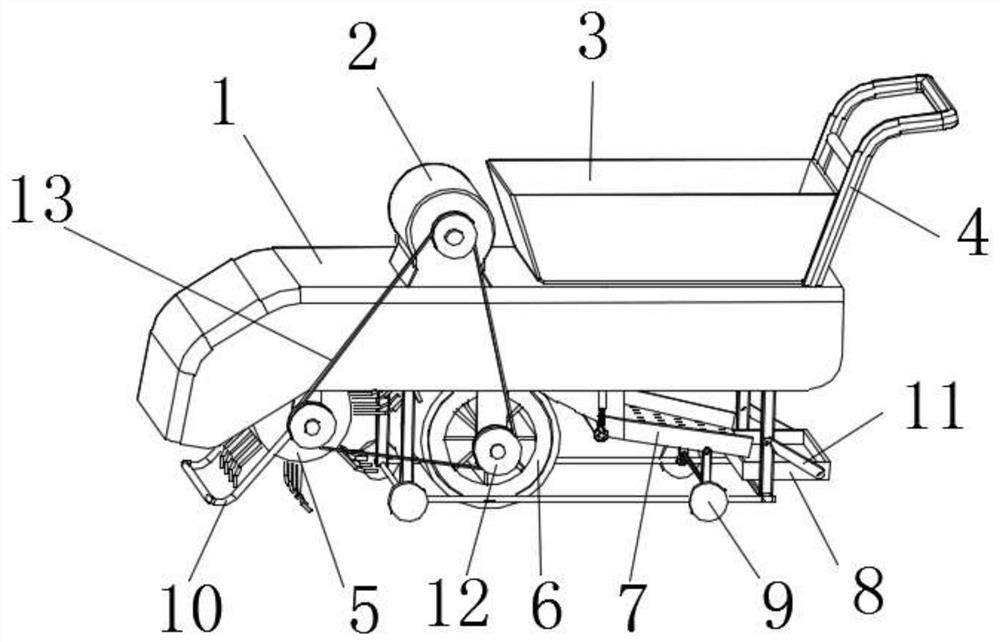

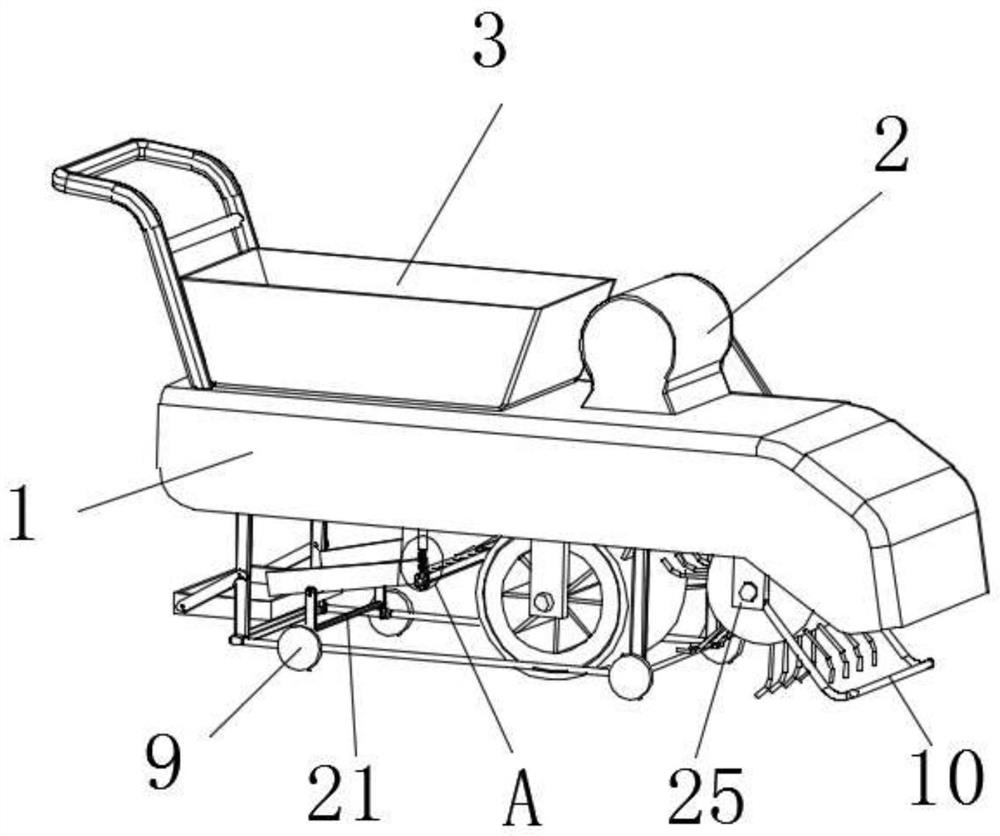

[0036] Example: see Figure 1-7 , a metal recovery device, including a frame 1. The frame 1 can be any frame structure in the prior art, such as a metal frame.

[0037] A driving device 2 is fixedly installed on the top of the frame 1 . The driving device 2 can be any one in the prior art, such as a motor.

[0038] The bottom of the frame 1 is provided with a plurality of rollers 9 .

[0039] A pair of front mounts 25 , a pair of middle mounts 26 and a pair of rear mounts 27 are fixedly mounted on the bottom of the frame 1 . A pair of front mounts 25, a pair of middle mounts 26 and a pair of rear mounts 27 can be fixedly mounted on the frame 1 by any means in the prior art, such as welding.

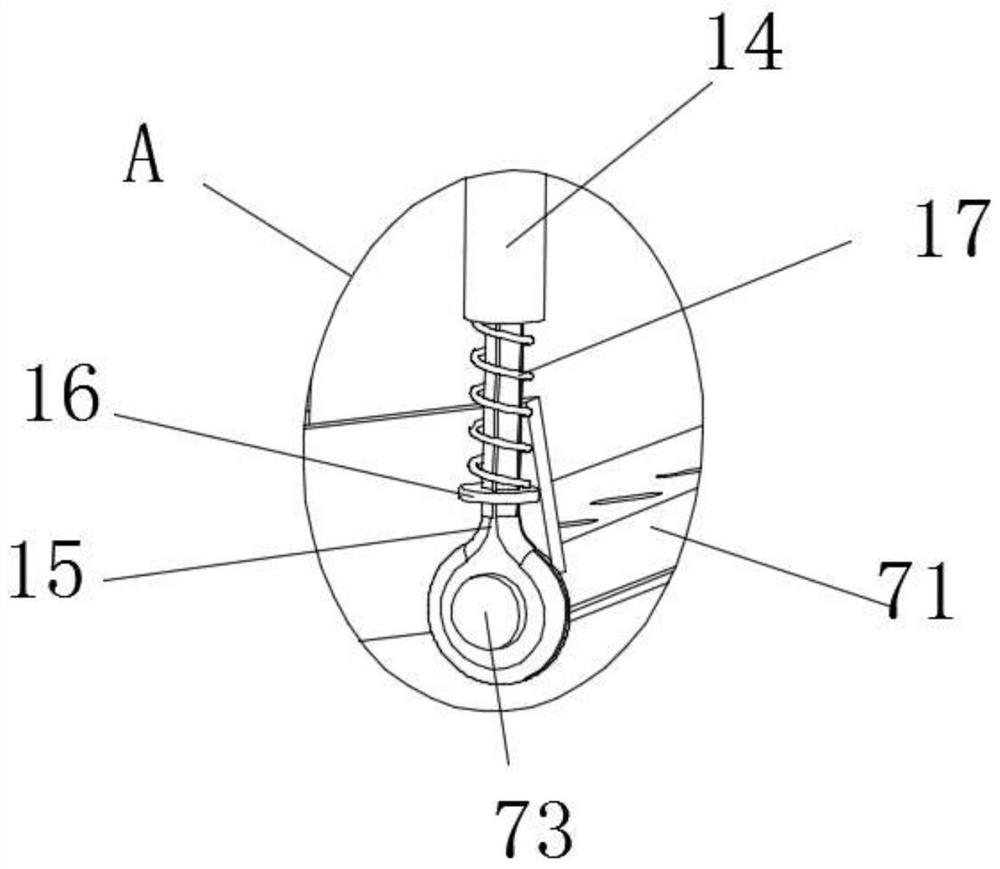

[0040] A second rotating shaft 52 is rotatably mounted on one side near the bottom of the pair of front mounting brackets 25 . The second shaft 52 can be any cylinder in the prior art, such as a metal rod

[0041] The loosening mechanism 5 is sleeved on the second rotating shaft 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com