Post-tensioning prestressed box girder double-duct type vacuum-assisted mud jacking system and construction method thereof

A vacuum-assisted, prestressed technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems affecting the quality and compactness of grouting, high labor costs, and poor sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

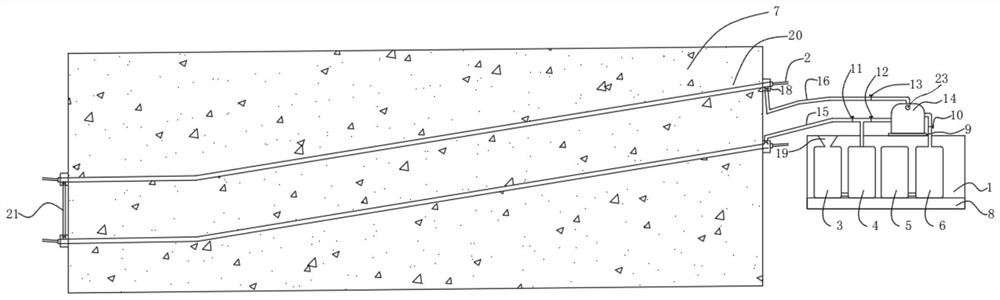

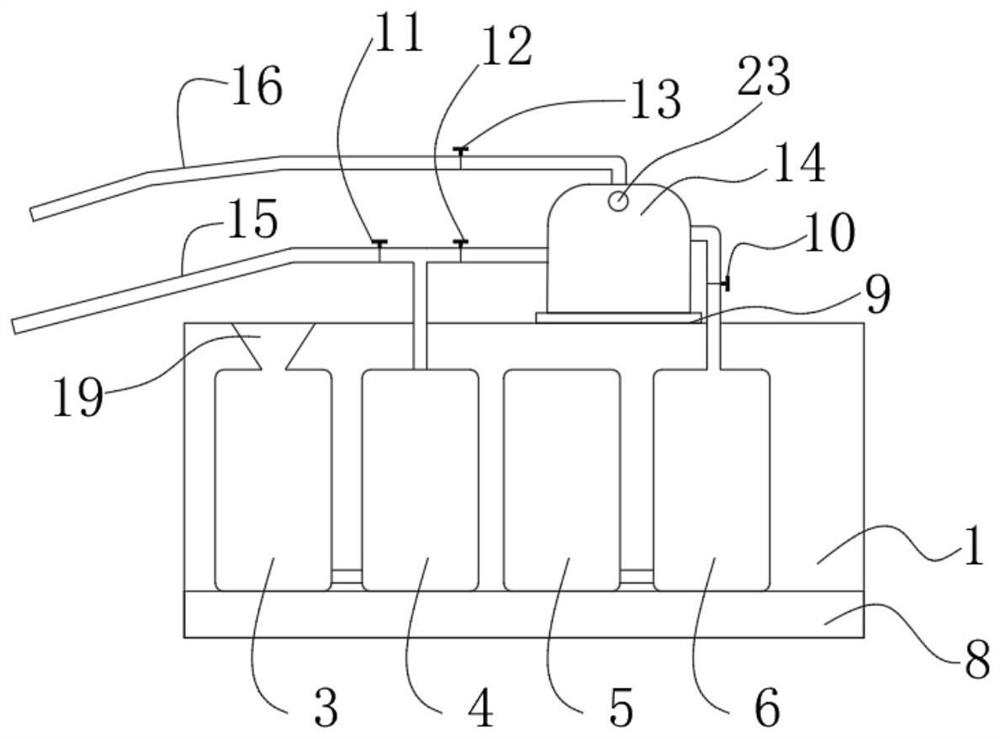

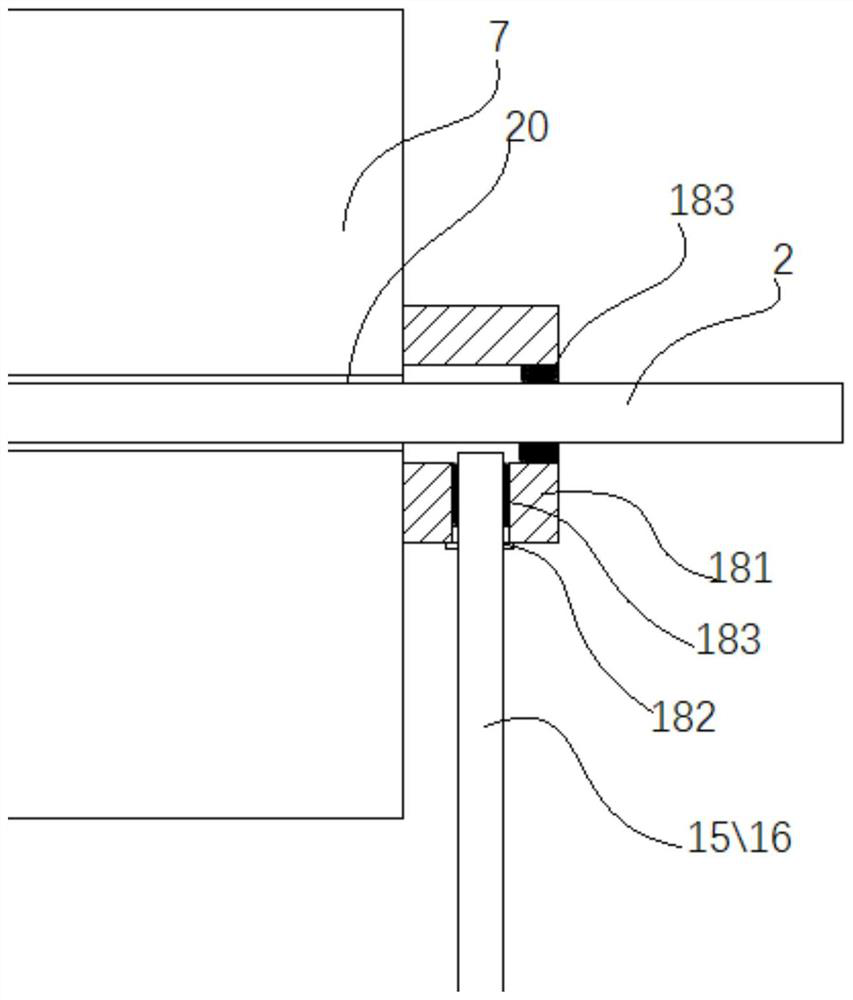

[0026] like figure 1 and figure 2 As shown, a post-tensioned prestressed box girder double-channel vacuum-assisted grouting system includes a vacuum-assisted grouting machine, a sealing assembly 18, a connecting pipe 21 and a vacuum degree measuring piece 22; The two ends of the stress reinforcement channel 20 are closed, the sealing assembly 18 has an external interface connected with the prestressing reinforcement channel 20, and the two ends of the connecting pipe 21 are respectively sealed and connected with the external interfaces at the tail ends of the two prestressing reinforcement channels 20, and the vacuum degree is measured Part 22 is used to measure the vacuum degree of the prestressed steel bar channel 20, and generally adopts a pressure gauge; the vacuum assisted grouting machine includes a mortar mixing chamber 3 with a mortar inlet 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com