Carbon steel high-speed rail axle with speed of not less than 400 kilometers per hour, and modification method thereof

A carbon steel and axle technology, applied in the field of carbon steel high-speed rail axle and its modification, can solve the problems of not meeting the application requirements of high-speed rail axles, low fatigue performance, etc., achieve good and uniform cooling, increase fatigue strength, and improve fatigue performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

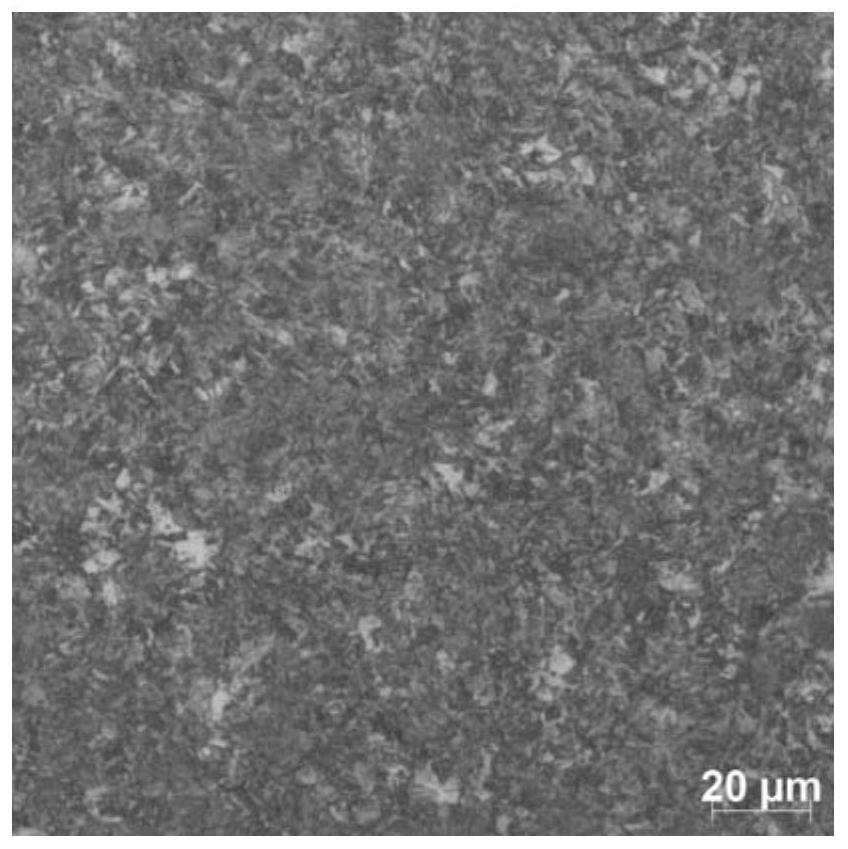

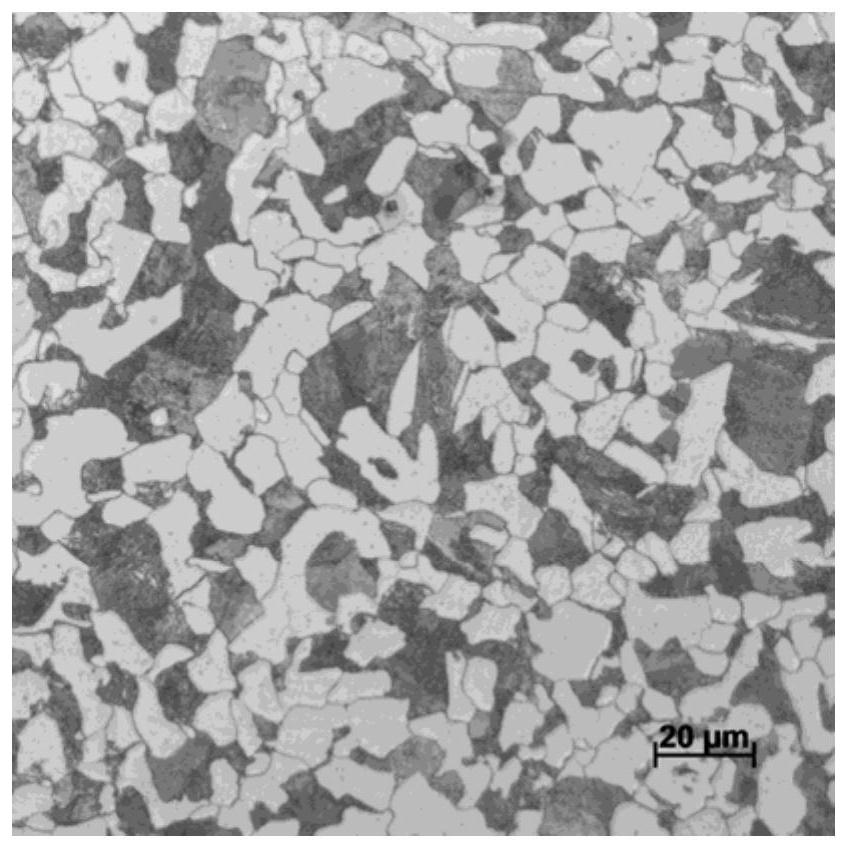

Image

Examples

Embodiment 1

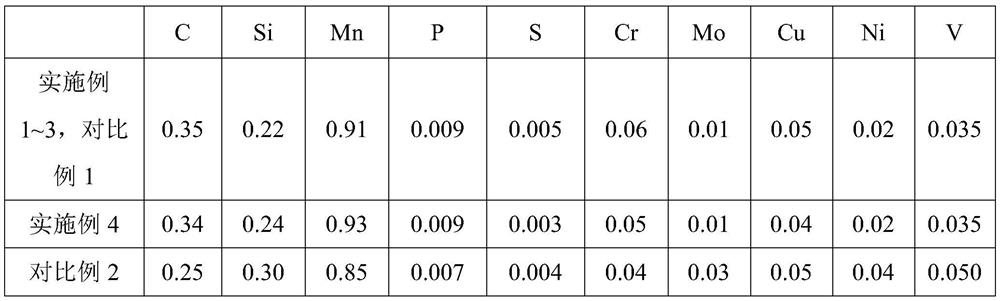

[0034] A carbon steel high-speed rail axle with a speed ≥ 400 kilometers per hour, comprising the following mass percentage components: as shown in Table 1, the balance not listed in Table 1 is Fe and unavoidable impurities.

[0035] Table 1 embodiment and comparative example chemical composition (unit: wt %)

[0036]

[0037] The production process of the carbon steel high-speed railway axle with a speed ≥ 400 kilometers per hour is as follows: axle blank forging → rough axle turning → axle end face processing → normalizing heat treatment → axle outer circle finishing turning → axle inner hole boring processing → outer Cylindrical grinding→flaw detection→laser quenching→cylindrical grinding.

[0038] The modification methods included in the above-mentioned production process include normalizing treatment and laser quenching.

[0039] The normalizing specifically includes: heating the axle to 860°C, keeping it warm for 7 hours, and then air cooling to below 300°C.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com