Method for stably operating bacteria-algae symbiotic aerobic granular sludge membrane bioreactor

A membrane bioreactor, aerobic granular sludge technology, used in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., to achieve long-term stable operation, reduce adhesion, and reduce clogging. effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

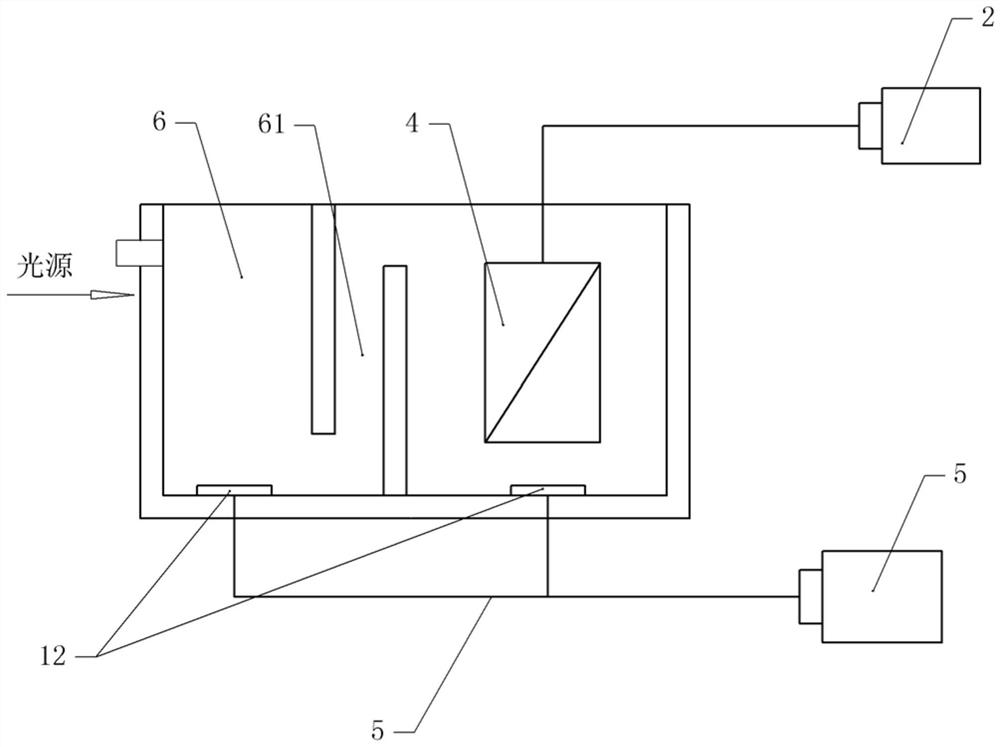

[0036] A method for the stable operation of a bacteria-algae symbiotic aerobic granular sludge membrane bioreactor, using a membrane bioreactor, basically as attached figure 1 As shown, the membrane bioreactor includes a body and a culture area 6 for cultivating bacteria and algae symbiotic aerobic granular sludge, and a sedimentation area 61 is arranged between the culture area 6 and the body. The light source used to cultivate the symbiotic aerobic granular sludge of bacteria and algae comes from sunlight. A membrane module is arranged in the main body, and a main water pipe 3 is arranged in the membrane module, and the main water pipe 3 is connected with a peristaltic pump 2 . The body and the bottom of the cultivation area 6 are provided with an aeration box, and also include an air pump 5, and the air pump 5 is communicated with a main air pipe communicating with the aeration box.

[0037] Including the following steps:

[0038] S1: Inoculate the mature bacteria-algae s...

Embodiment 2

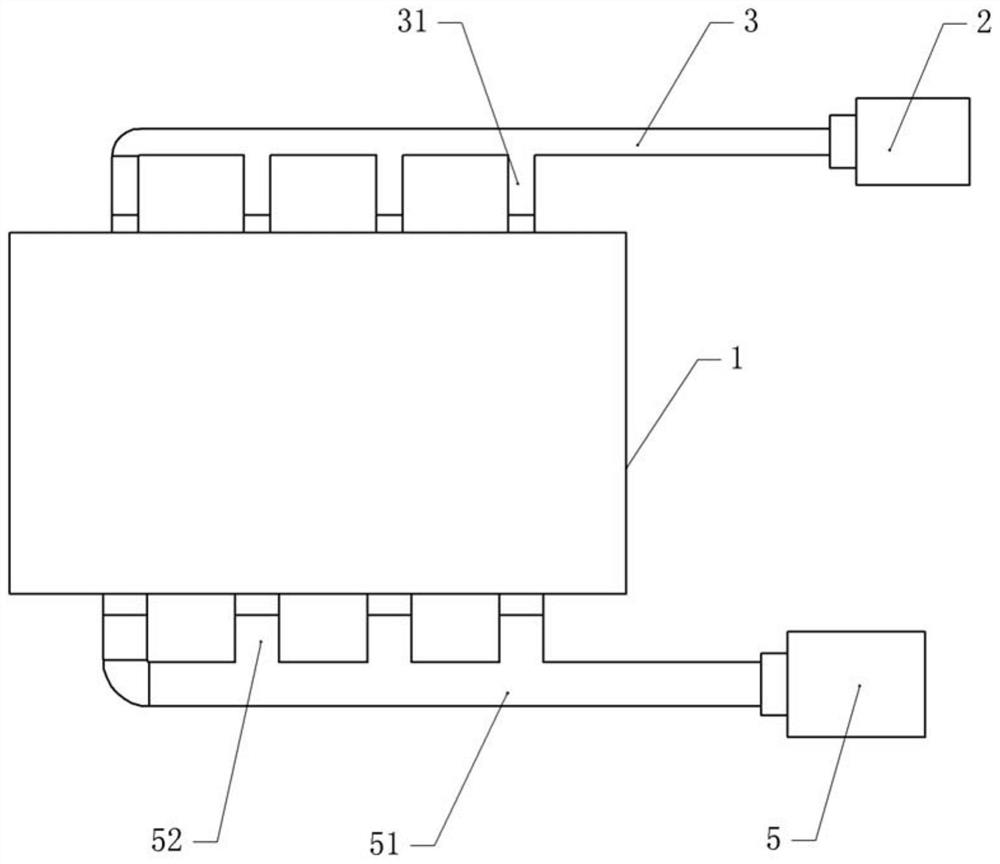

[0053] The difference between the second embodiment and the first embodiment is that the attached figure 2 And attached image 3 As shown, the membrane bioreactor includes a frame and a body 1 installed on the frame, and the body 1 is provided with a sewage outlet 11 .

[0054] Several membrane assemblies 4 are arranged in the body 1, and the membrane assemblies 4 include a bracket 14 and a filter membrane 15 arranged on the bracket 14. The upper part of the filter membrane 15 is rotatably connected with a support plate 16 fixedly connected with the body 1 by bolts, so as to support the filter membrane Stable support. An auxiliary water pipe 31 is arranged in the filter membrane 15, and a peristaltic pump 2 is fixed on the frame. The bottom of the membrane module 4 is provided with an aeration box 12 which is bolted to the body 1 , and the top wall of the aeration box 12 is provided with an air hole 13 . The aeration boxes 12 are all communicated with an auxiliary air pipe...

Embodiment 3

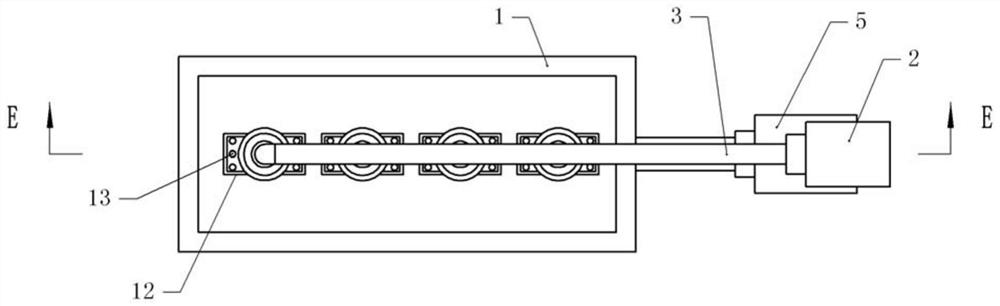

[0064] The difference between embodiment three and embodiment one is that, as attached Figure 6 As shown, the membrane module 4 includes a bracket 14 and a filter membrane 15 , the filter membrane 15 is screwed on the bracket 14 , the bottom of the bracket 14 protrudes into the aeration box 12 , and the bracket 14 is rotatably connected with the aeration box 12 . The bottom bolt of the bracket 14 is fixed with the fan blade 17 located in the aeration box 12 , and the fan blade 17 is located at the connection between the aeration box 12 and the secondary air pipe 52 . Of course, the aeration box 12 in the cultivation area 6 is also rotatably connected with fan blades 17 .

[0065] When performing S3, the gas enters the aeration box 12, the gas will push the fan blade 17 to rotate, the fan blade 17 will drive the bracket 14 to rotate, and then the bracket 14 will drive the filter membrane 15 to rotate. When the filter membrane 15 rotates, the centrifugal force Under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com