A screw conveyor with variable pitch

A screw conveyor and variable technology, applied in the field of conveyors, can solve the problems of worn blades, insufficient support strength, stuck gravel, etc., and achieve the effect of improving support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that those skilled in the art to which the invention pertains can easily realize these embodiments, however, the present invention can also be realized in various forms , so the present invention is not limited to the embodiments described below, and in addition, in order to describe the present invention more clearly, components not connected with the present invention will be omitted from the drawings.

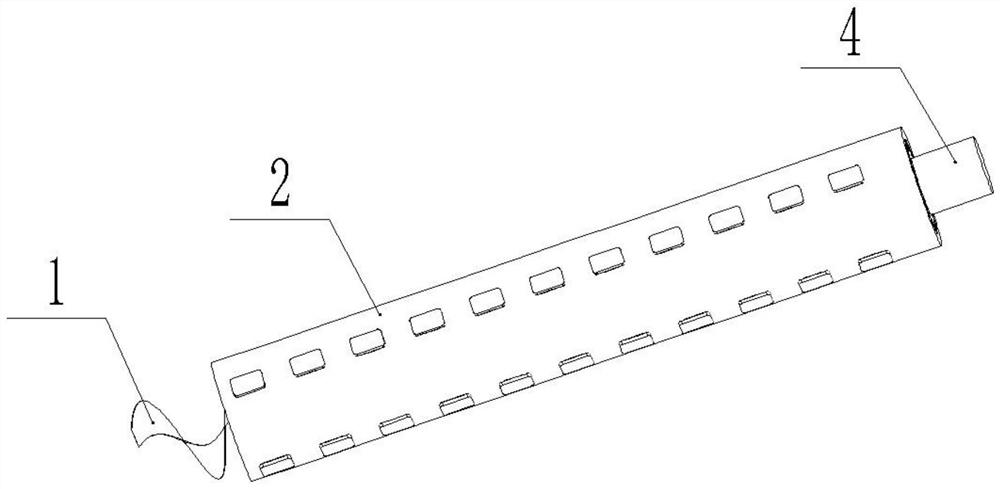

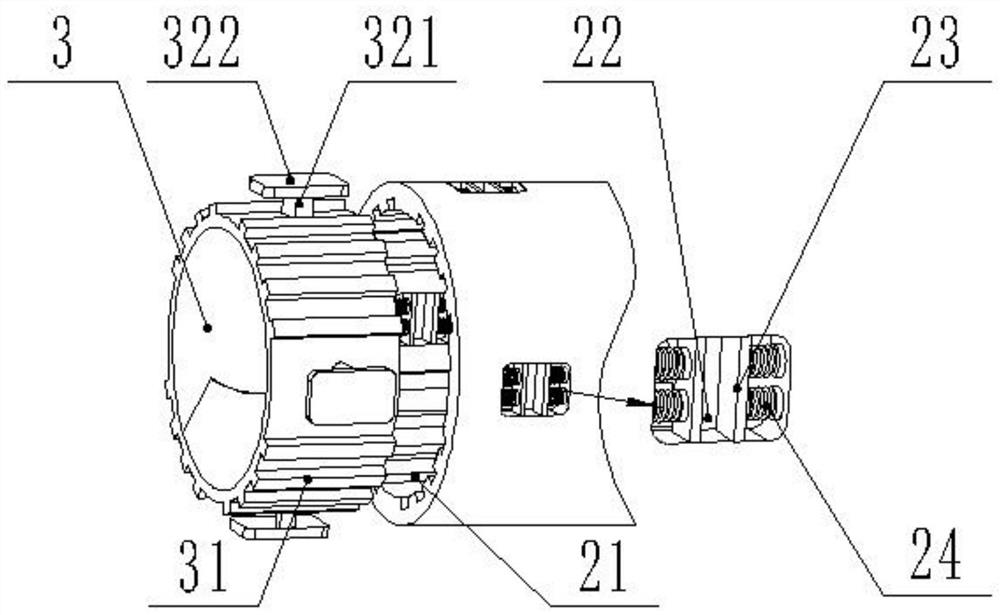

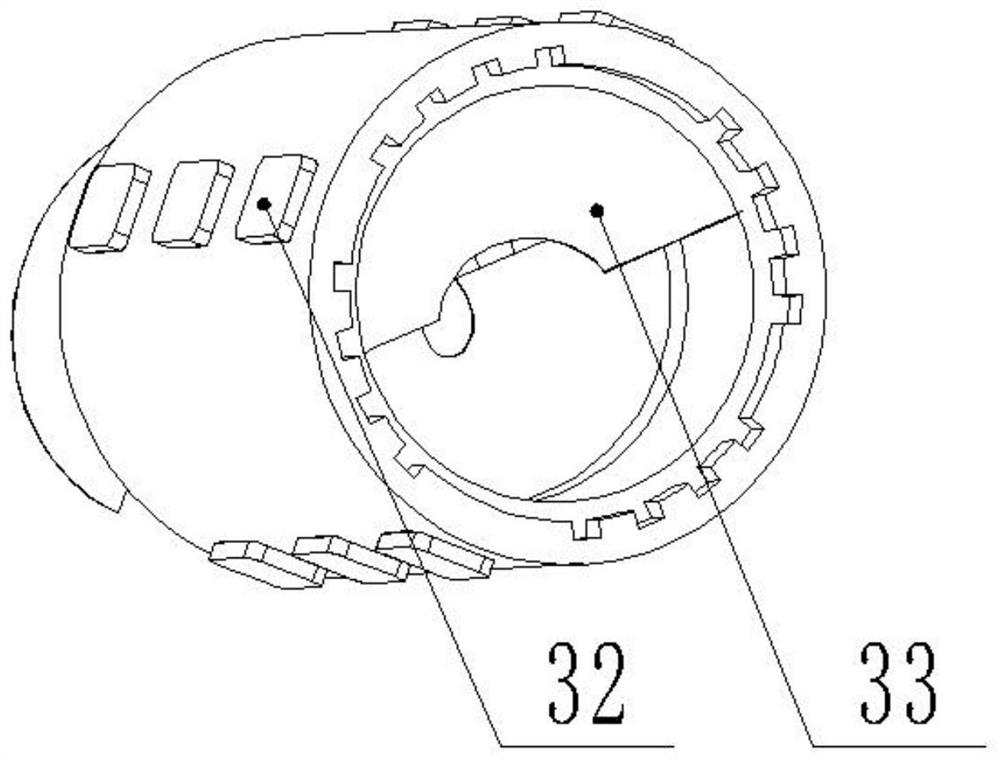

[0020] like figure 1 , 2 As shown, a screw conveyor with variable pitch includes: screw input end 1, outer cylinder 2, inner cylinder 3, transmission mechanism 4;

[0021] like figure 1 As shown, the screw input end 1 is located at the front end of the whole, that is, the entrance for transporting muck, and transports the dregs and gravels it contacts into the entire pipeline through rotating motion;

[0022] like figure 1 , 2 As shown, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com