Positive displacement wire and cable sheath extruding machine and extruding method thereof

A wire and cable, volumetric technology, applied in volumetric wire and cable sheath extruder and its extrusion field, can solve the problems of affecting the compactness of the rubber material, reducing the strength and toughness of the sheath, and waste of raw materials, etc., to achieve guaranteed strength and toughness, improved compactness, uniformity of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

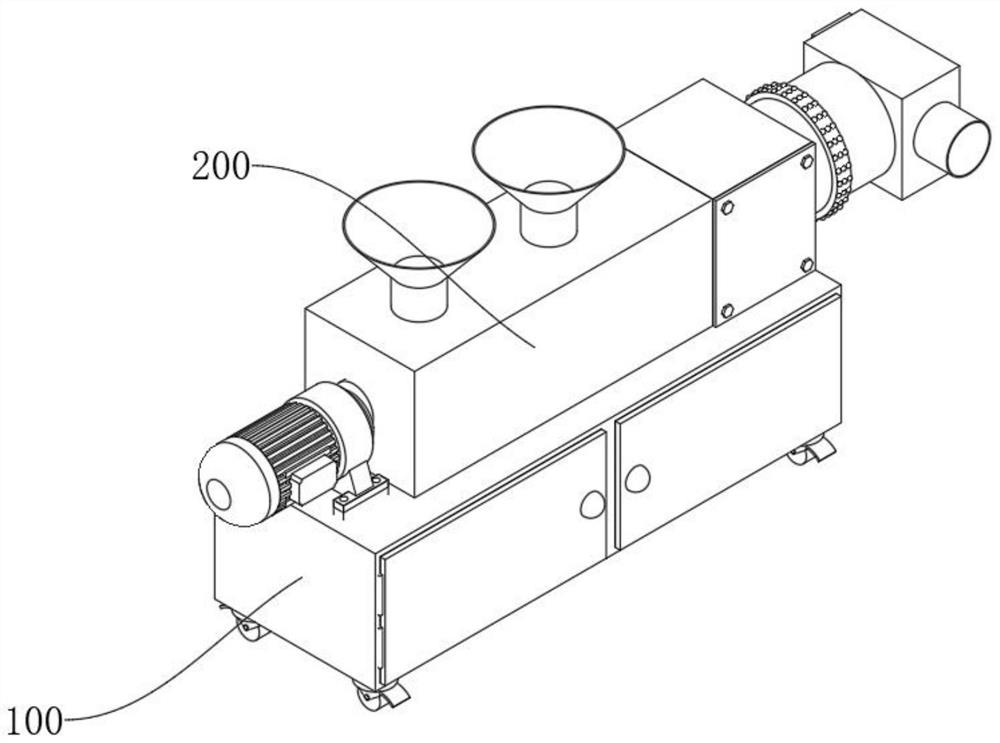

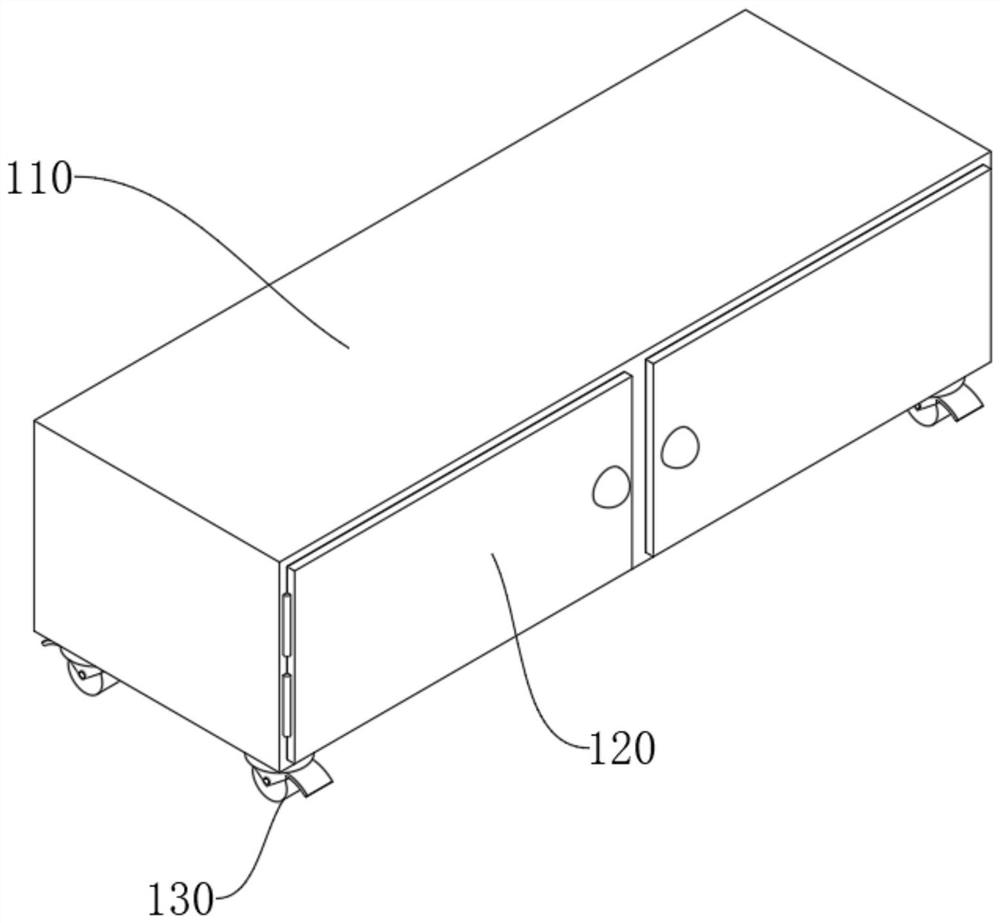

[0056] see Figure 1-Figure 12 As shown, this embodiment provides a volumetric wire and cable sheath extruder, including a support base 100 and an extrusion mechanism 200 arranged on the top of the support base 100. The extrusion mechanism 200 at least includes:

[0057] The screw conveying device 210, the screw conveying device 210 includes a stirring box 211, the top and the bottom of the inner cavity of the stirring box 211 are embedded with electric heating elements 214, and the electric heating elements 214 are heating PTC thermistors with constant temperature heating characteristics. After the thermistor is powered on, the self-heating temperature rises to make the resistance value enter the transition zone, and the surface temperature of the constant temperature heating PTC thermistor will maintain a constant value, and the electric heating element 214 can generate heat, so that the raw materials inside the stirring box 211 melt into a gel, and the stirring box 211 A sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com