A processing method for grid structure parts

A grid structure and processing method technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of difficult size assurance, no plane, poor rigidity of parts, etc., to improve strength and surface quality, reduce Clamping length of the tool and the effect of improving the rigidity of the part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

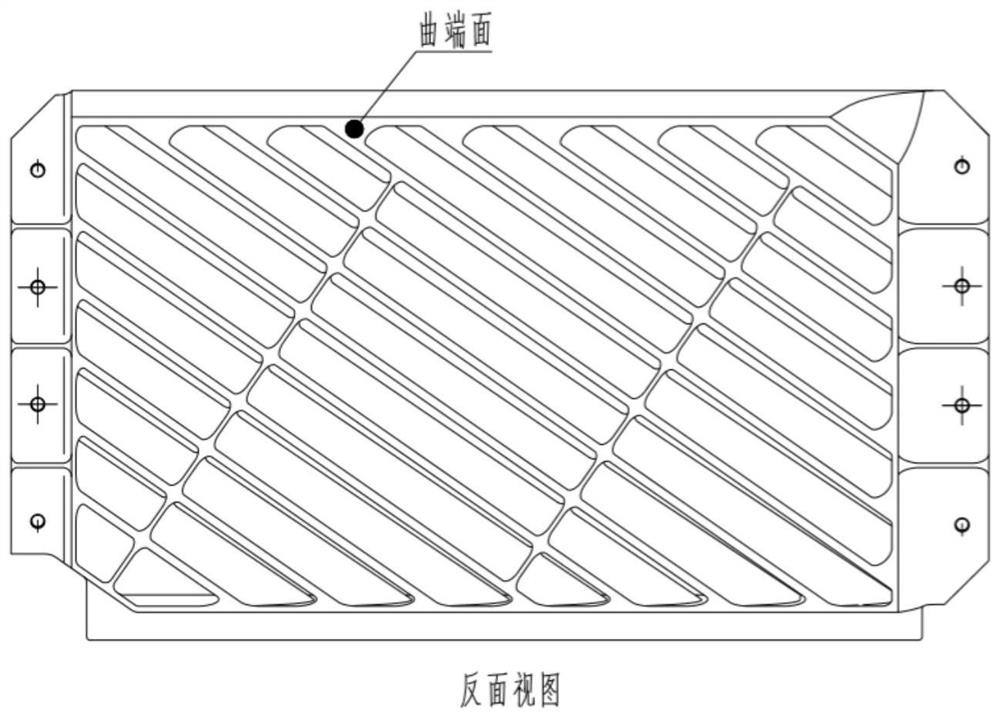

[0044] In this embodiment, the final molding diagram of the grid structure part is as follows Figure 1 to Figure 3 As shown, the processing ideas of the grid structure parts are as follows:

[0045] Rough milling parts. Mill out the grid in the middle and the process edges around, remove most of the allowance, and leave a uniform allowance for subsequent processing, such as Figure 4 and Figure 5 . When rough milling, keep the wool on the reverse side of the installation side to ensure that it is the same height as the left and right side craft edges. The rough milling of the intermediate grid is carried out in the following order: the first rough milling on the front side (rough milling when the part is mounted with the front facing up), and rough milling on the reverse side (roughing when the part is mounted with the rear facing up). mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com