Automatic locking device for core roller of ring rolling machine

An automatic locking, core roll technology, applied in metal rolling and other directions, can solve the problems of shortening the core roll installation time, core roll falling off, bolt loosening, etc., to save physical strength and time, improve firmness, and avoid core rolls shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

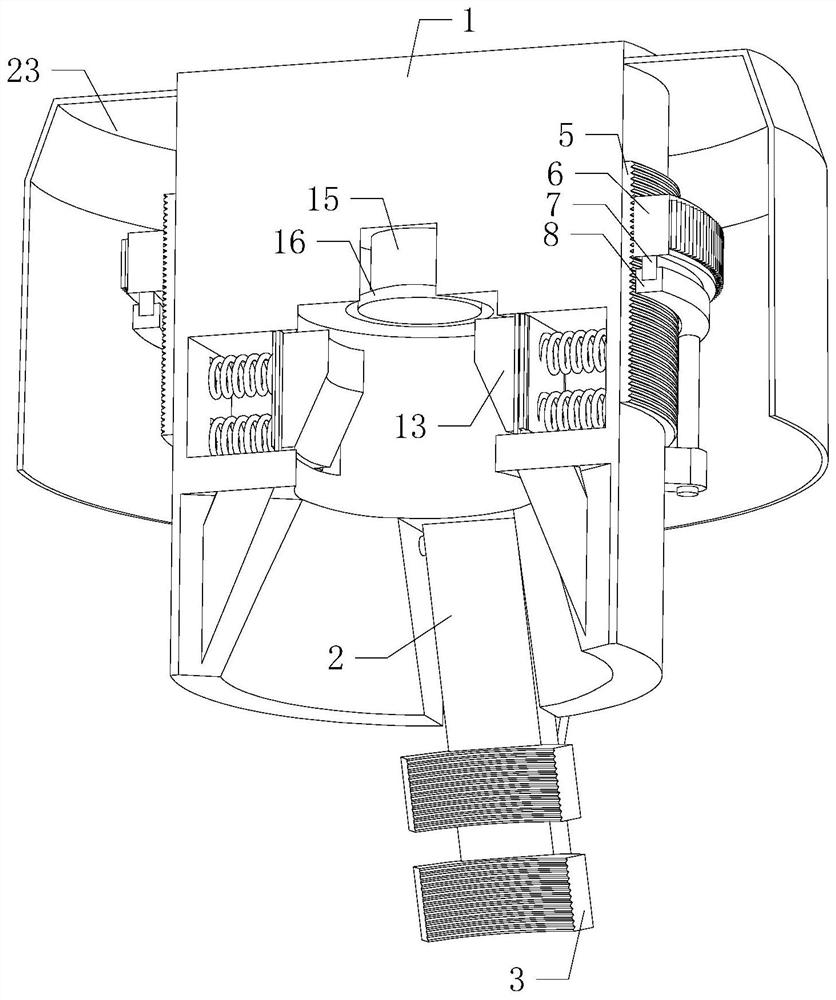

[0019] Such as Figure 1 to Figure 4 As shown, an automatic locking device for ring rolling mandrel rolls of the present invention inserts the top of the external core roll into the jack when it is working, and the tapered surface on the lower side of the inner wall of the jack can easily guide the core roll. The top of the core roller is in contact with the top of the inner wall of the socket, and two sets of motors 9 are turned on. The two sets of motors 9 respectively drive two sets of long gears 12 to rotate through two sets of rotating shafts 10. Both sets of long gears 12 mesh with the internal thread ring 6. The long gear 12 drives the inner threaded ring 6 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com