An integrated high-efficiency steel slag grinding and iron recovery system and method

A steel slag and high-efficiency technology, which is applied in the field of steel slag integrated high-efficiency grinding and iron recovery systems, can solve the problems of difficulty in large-scale comprehensive utilization of steel slag, low iron recovery rate, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

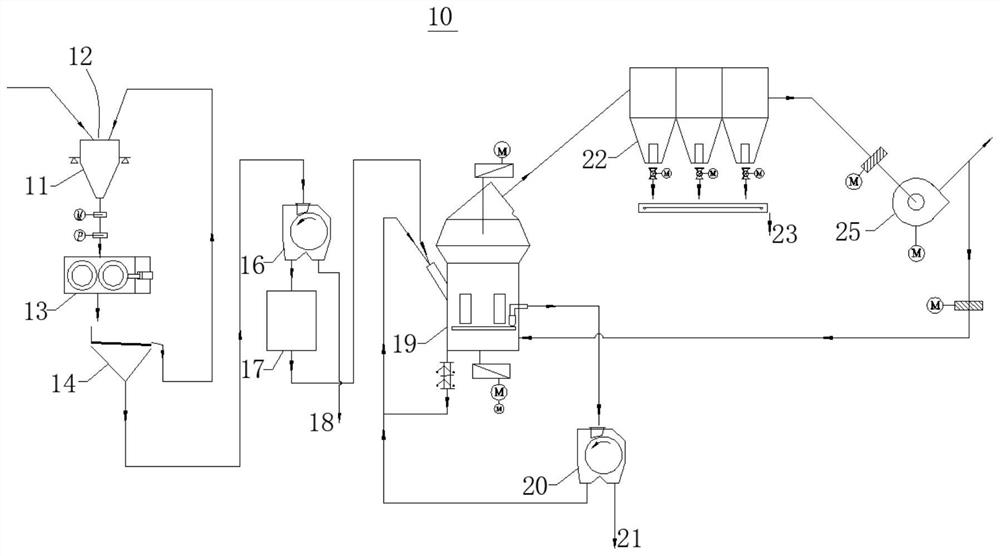

[0056] Cooperate see figure 1 , the present embodiment provides a steel slag integrated high-efficiency grinding and iron recovery system 10, which includes a steady flow bin 11, the steady flow bin 11 has a steel slag feeding port 12; the steady flow bin 11 is connected to a roller press 13, and the roller press The machine 13 is connected to the vibrating screen 14, the return port of the vibrating screen 14 is connected to the roller press 13, and the discharge port is connected to the magnetic separator 16; one way of the magnetic separator 16 is connected to the intermediate storage bin 17, and the other is connected to the slag steel Storage 18; the middle storage bin 17 is connected to the vertical mill 19, and the vertical mill 19 is connected to another magnetic separator 20 all the way, and the magnetic separator 20 is connected to the iron powder storage 21 one way, and the other way is connected to the entrance of the vertical mill 19, The other road of the vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com