HNB tobacco shred atomizing agent processing device

A processing device and atomizing agent technology, applied in the manufacture of cigars, tobacco, food science, etc., can solve the problems of tobacco cell damage, tobacco quality reduction, etc., to prevent leaf clumping, improve core quality, and maintain sensory perception quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

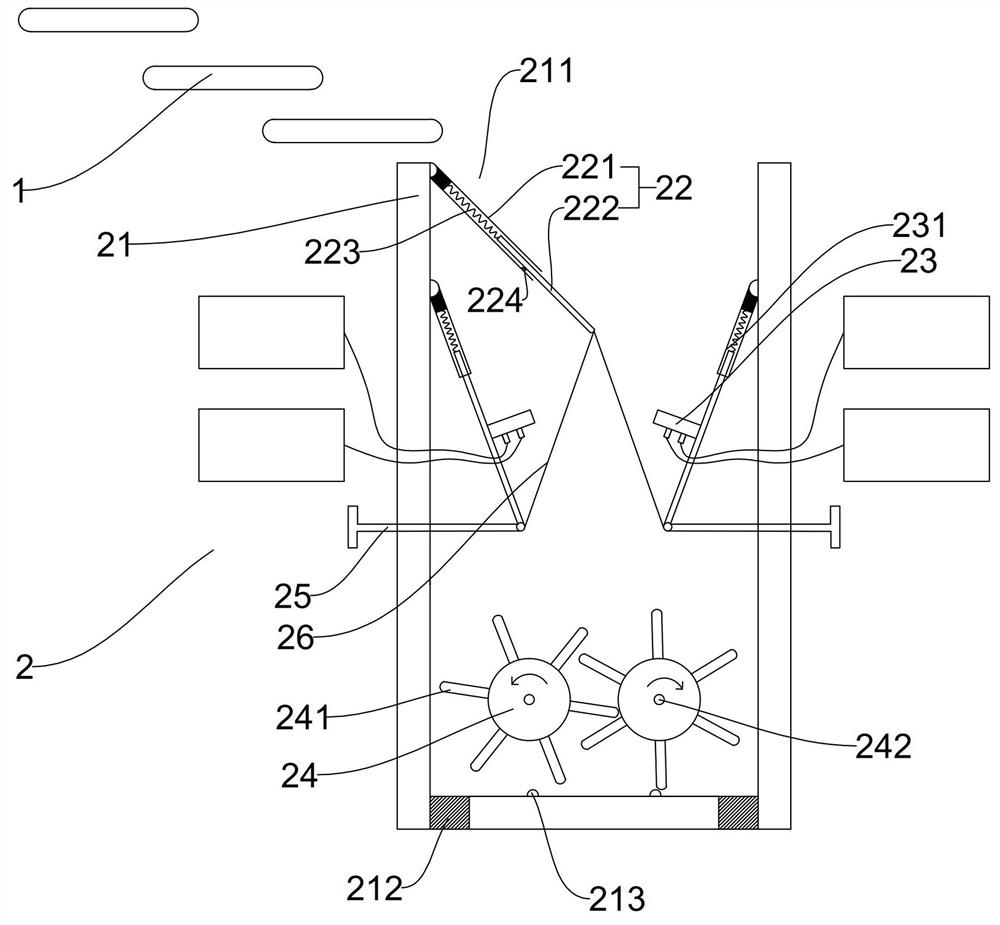

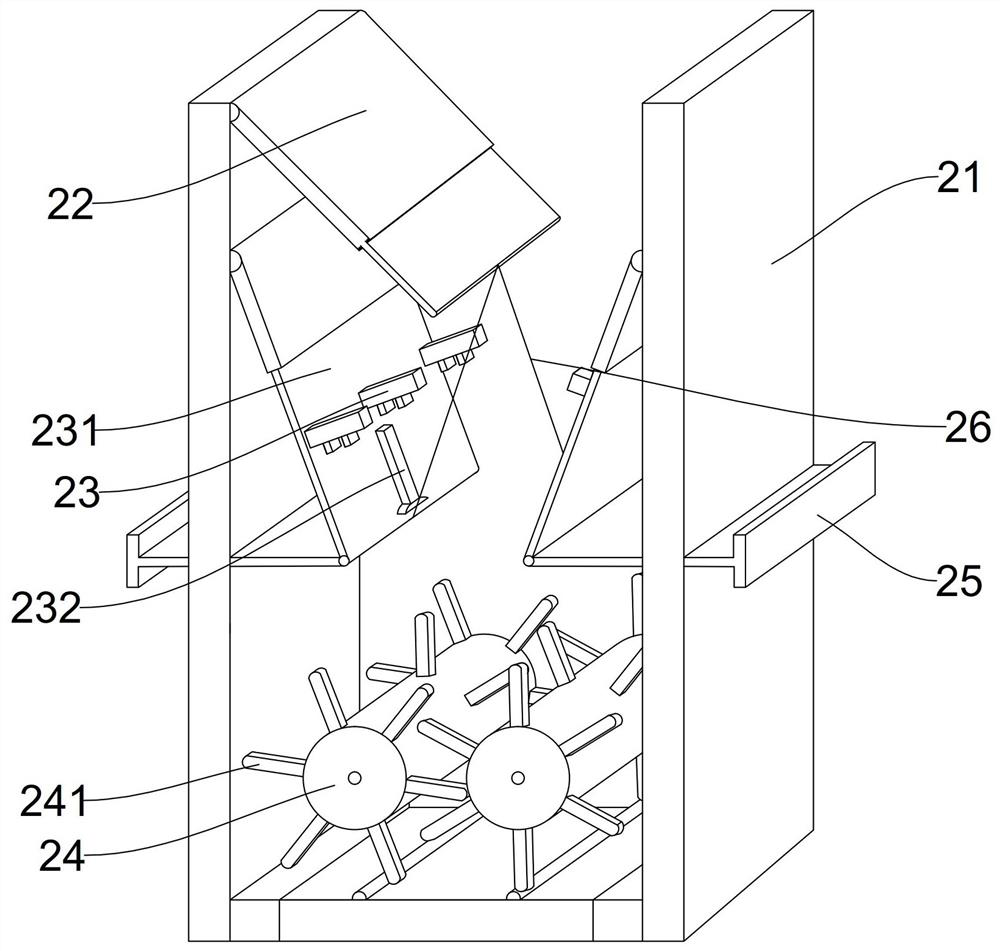

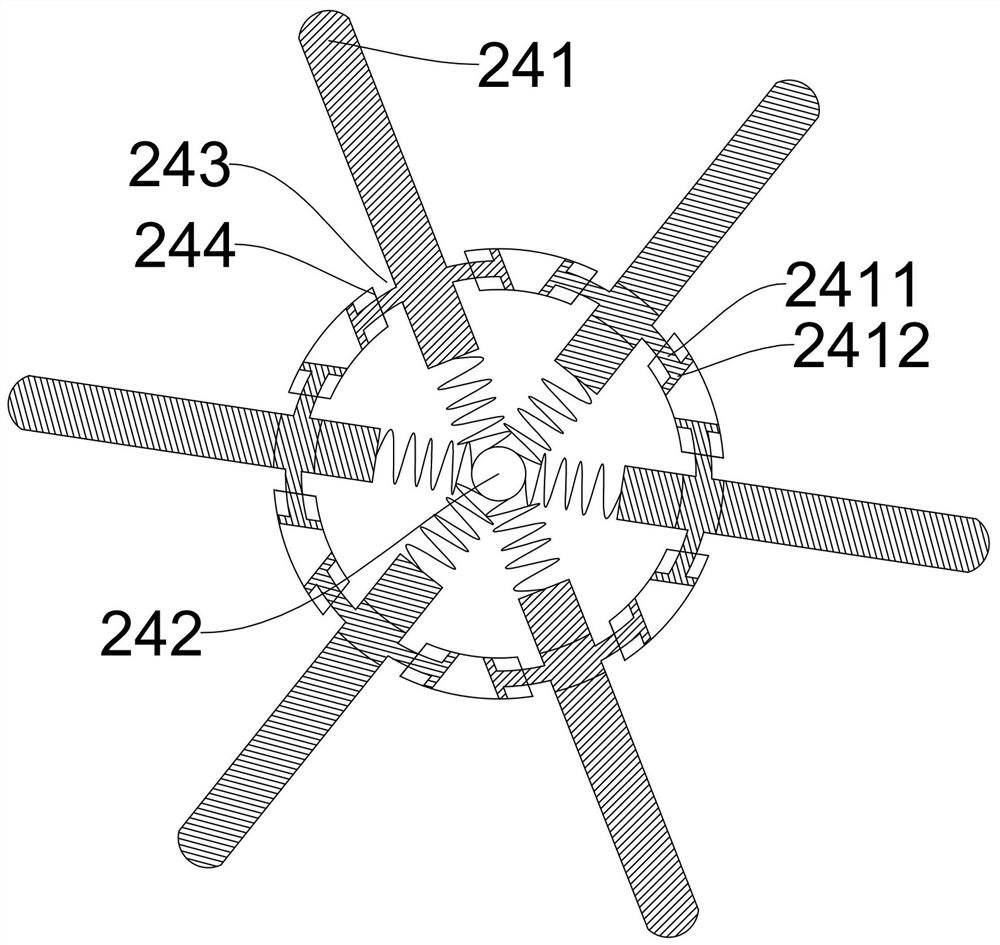

[0022] A kind of HNB leaf silk atomizer processing device, such as figure 1 As shown, it includes a magnetic high-frequency vibrating tank 1 for distributing the filaments and an atomizer feeding device 2 for feeding the filaments.

[0023] Wherein, the magnetic high-frequency vibrating tank 1 evenly thins the blade silk through small-scale high-frequency vibration. In this embodiment, in order to improve the degree of thinning of the shreds, at least three magnetic high-frequency vibration grooves 1 are provided, and several magnetic high-frequency vibration grooves 1 are arranged in a trapezoidal shape, so that the outlet of one magnetic high-frequency vibration groove 1 is located at the entrance of another magnetic high-fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com