A motor structure

A technology of motor structure and motor casing, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as bearing lockup, and achieve the effects of avoiding bearing lockup, reducing noise, and increasing bearing self-aligning force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

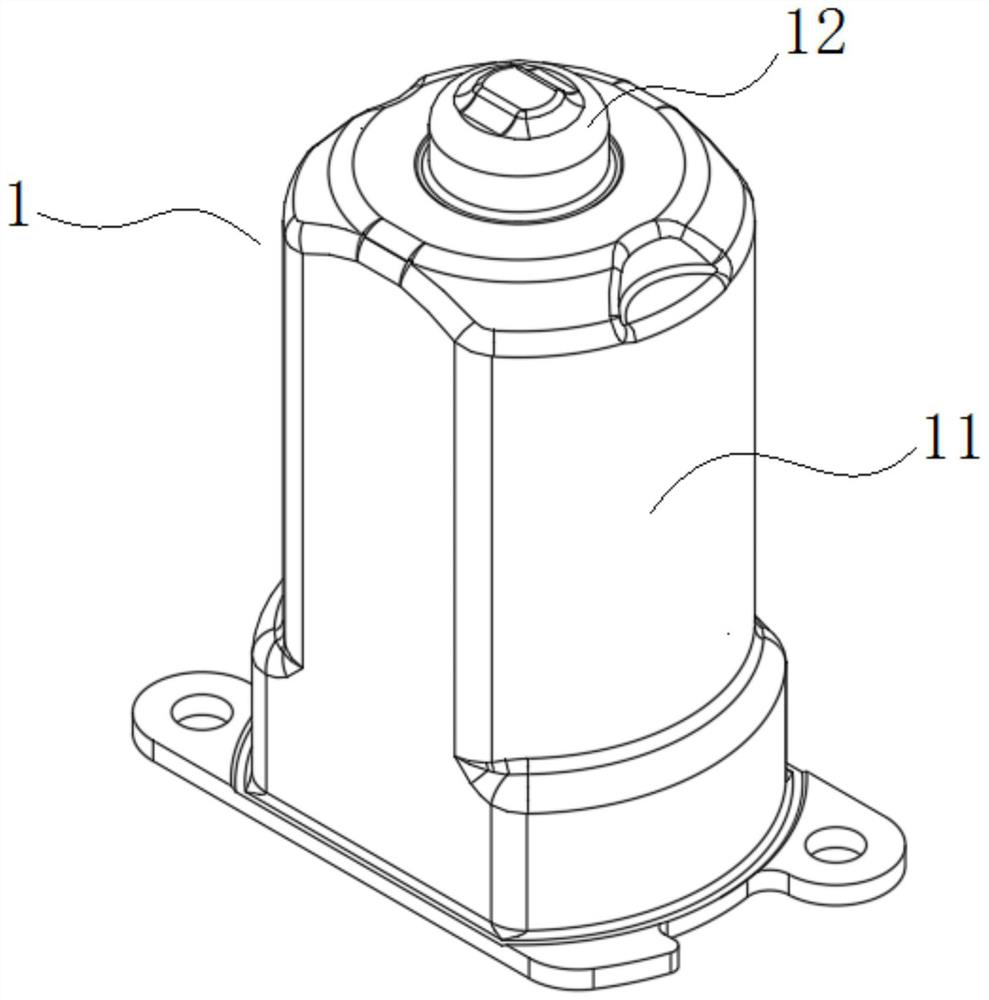

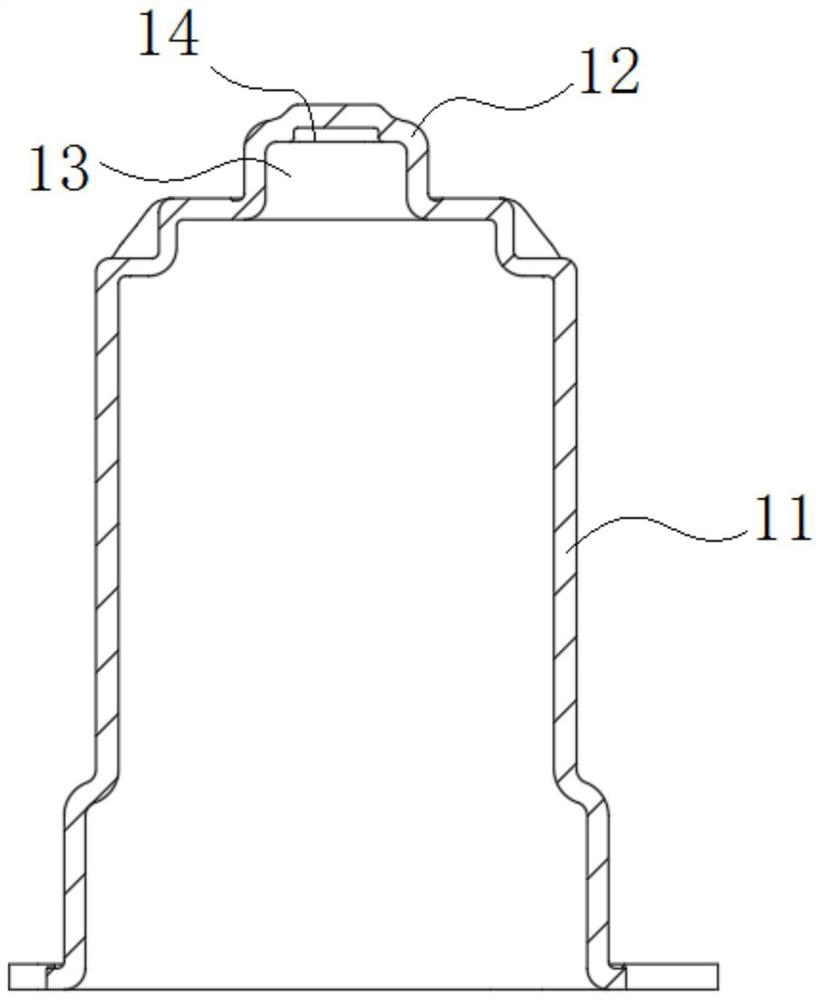

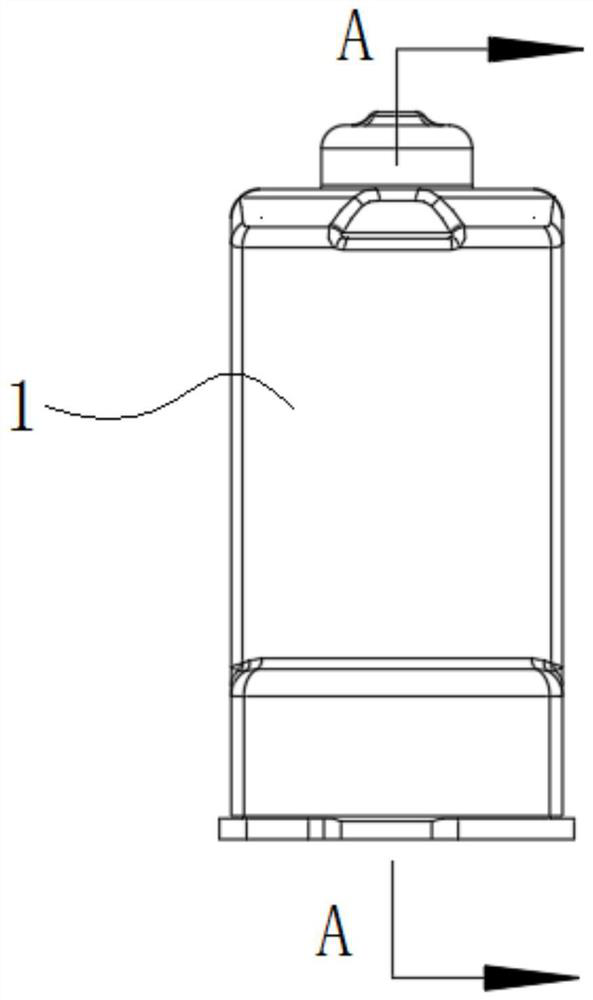

[0030] Figure 1 to Figure 9 As shown, the present invention provides a motor structure, including a motor 1, specifically, the motor 1 includes a motor housing 11, a motor body 2, a bearing fixing seat 3 and a bearing 4; There is a seat cavity 13 inside the platform 12 and the boss 12, and the seat cavity 13 is used to install the bearing fixing seat 3; the bearing fixing seat 3 is arranged in the seat cavity 13, and the bearing 4 is arranged in the bearing fixing seat 3, thereby forming Bearing installation structure; further, the motor body 2 is arranged in the motor housing 11, and its main shaft 21 extends into the bearing hole 41 of the bearing 4; and the main shaft 21 can rotate in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com