Photovoltaic and gas complementary power generation direct-current driving oil pumping unit system

A complementary power generation and DC drive technology, applied in photovoltaic power generation, electric vehicles, collectors, etc., can solve the problems of power supply and transmission facilities occupying cultivated land, etc., achieves strong practicability, saves the process of wiring and power point selection, and has good scalability and the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

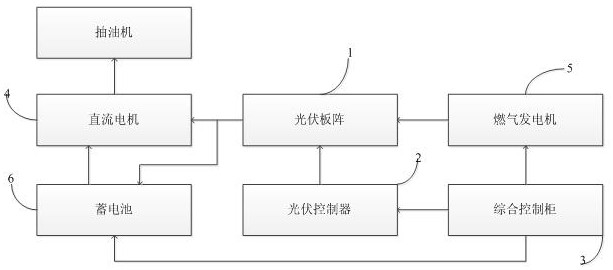

[0021] refer to figure 1 , the present invention provides a photovoltaic and gas complementary power generation DC drive pumping unit system, including: photovoltaic panel array 1, photovoltaic controller 2, integrated control cabinet 3, DC motor 4, gas generator 5 and battery 6; wherein, Photovoltaic panel array 1 is connected to photovoltaic controller 2, photovoltaic controller 2 is connected to integrated control cabinet 3 and battery 6, integrated control cabinet 3 is connected to gas generator 5 and DC motor 4, gas generator 5 is connected to photovoltaic controller 2, and DC motor 4 Connected to the pumping unit; the integrated control 3 is connected to the storage battery 6, and by judging the real-time power co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com