Full-parametric three-dimensional modeling method for elbow-shaped draft tube

A technology of three-dimensional modeling and draft tube, which is applied in the fields of electrical digital data processing, design optimization/simulation, special data processing applications, etc., can solve problems such as surface and entity errors, many operation steps, and structural optimization cannot be carried out smoothly, etc., to achieve The effect of ensuring consistency, ensuring accuracy and reliability, and shortening the time for design modeling and modification updates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

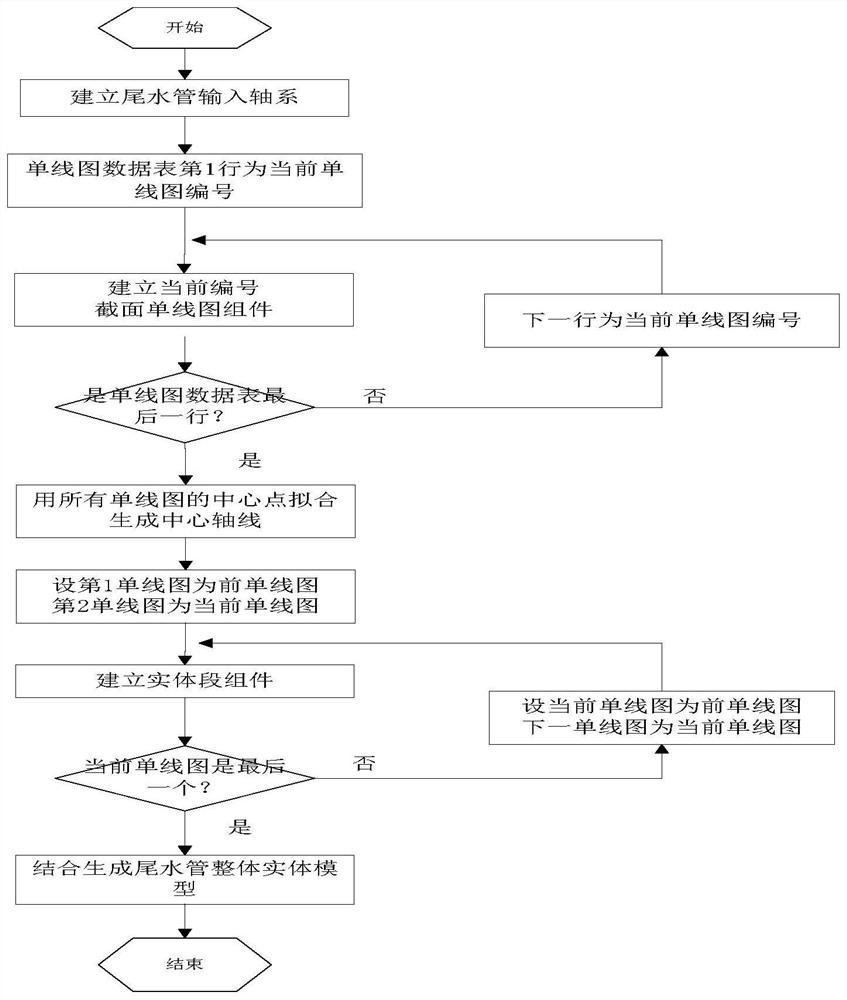

[0047] A method for fully parametric three-dimensional modeling of an elbow-shaped draft tube, comprising the following steps:

[0048] 1) Establish the draft tube input shaft system, the shaft system is a right-hand system, the origin of the shaft system is the center point of the bottom surface of the elbow-shaped draft tube cone section, the Y axis of the shaft system is the negative elevation direction of the center line of the unit, and the X axis is the downstream flow direction;

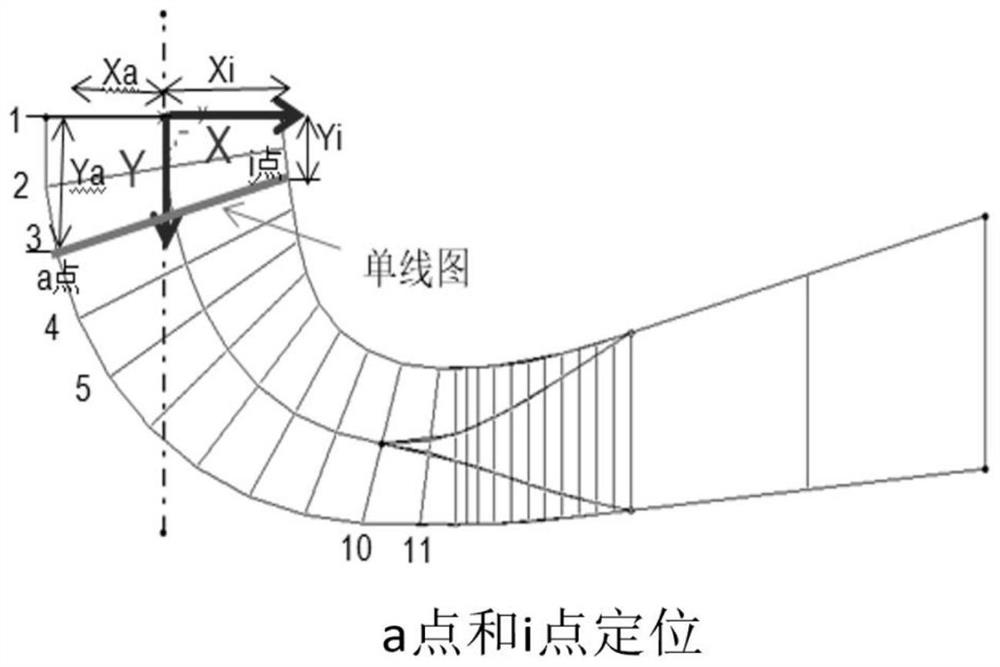

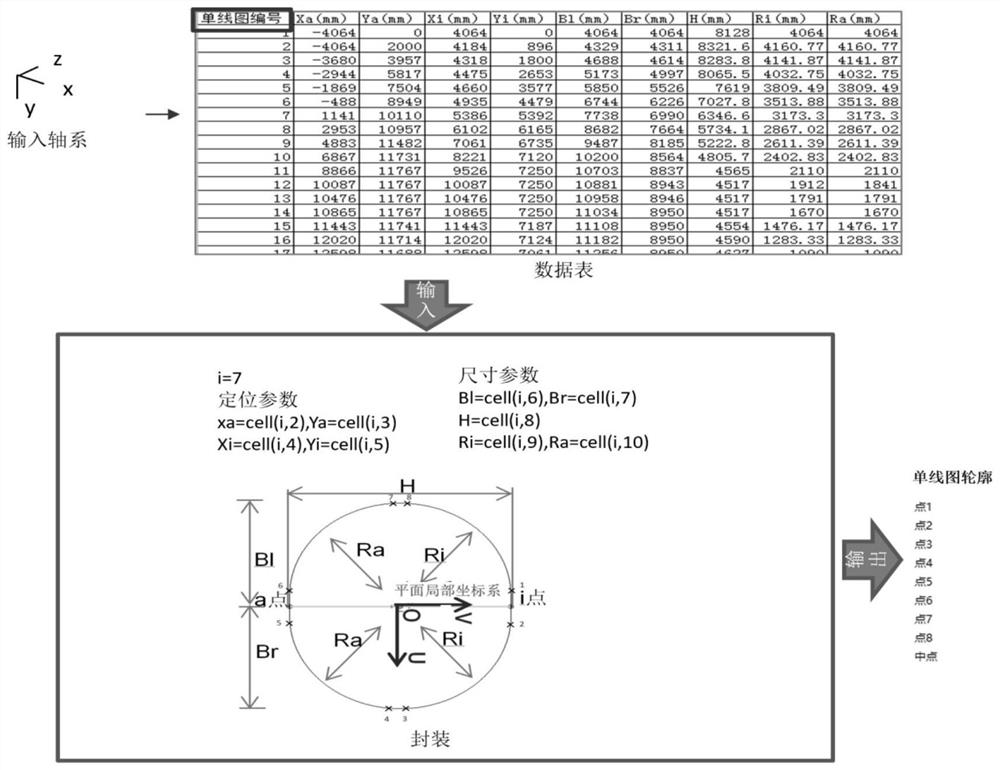

[0049] 2) Establish the section one-line diagram component, the input element is the draft tube input shaft system, the input parameters are the one-line diagram data table and the one-line diagram number, and the output section one-line diagram, 8 extreme points and 1 center point, and 8 extreme values Points are used for the node coupling of adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com