Robot hydrostatic pressure test device

A hydrostatic pressure and test device technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve problems such as safety accidents of tested robots and test personnel, and improve safety and convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

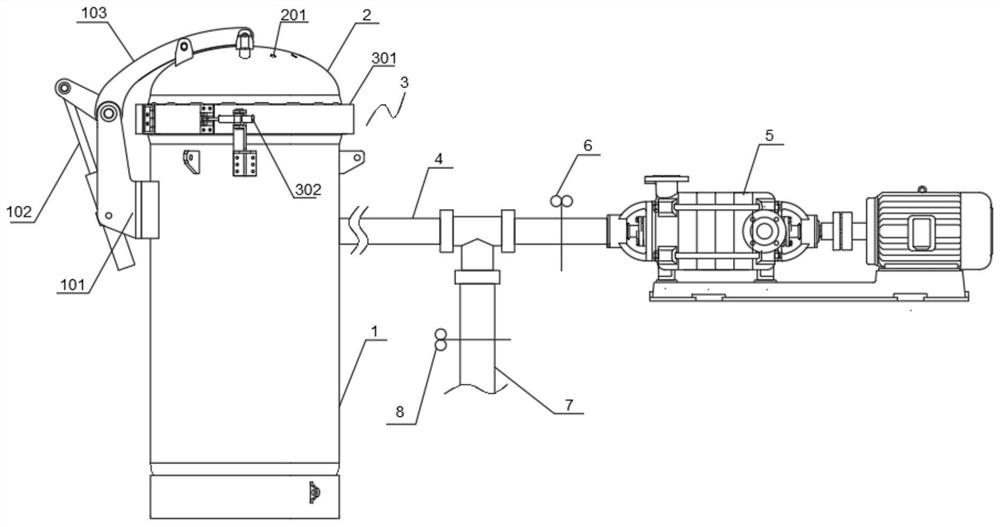

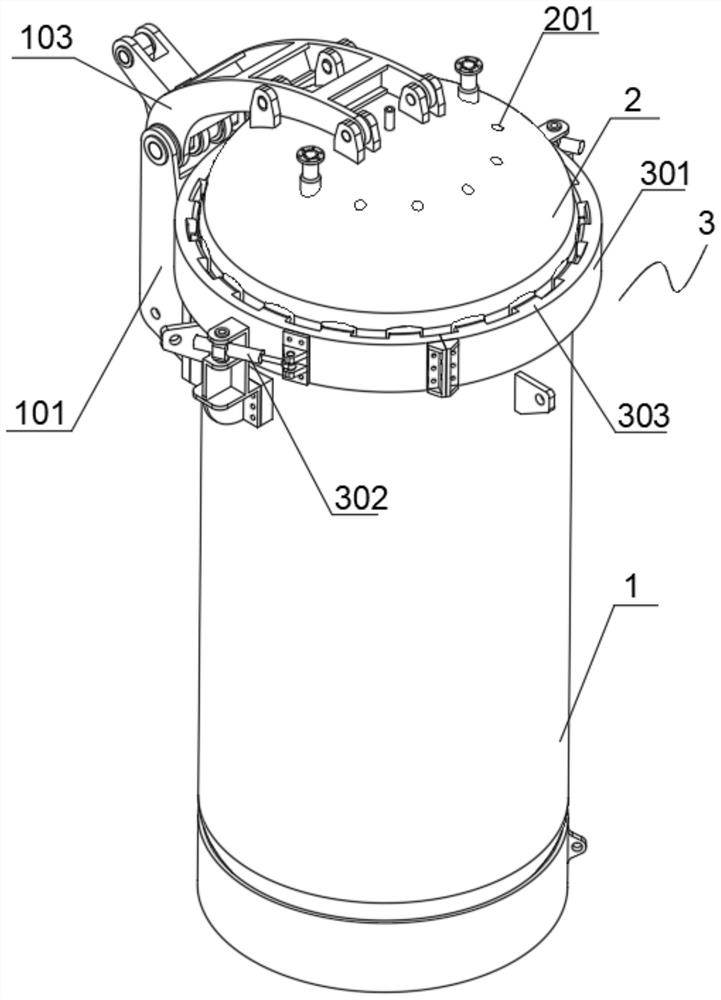

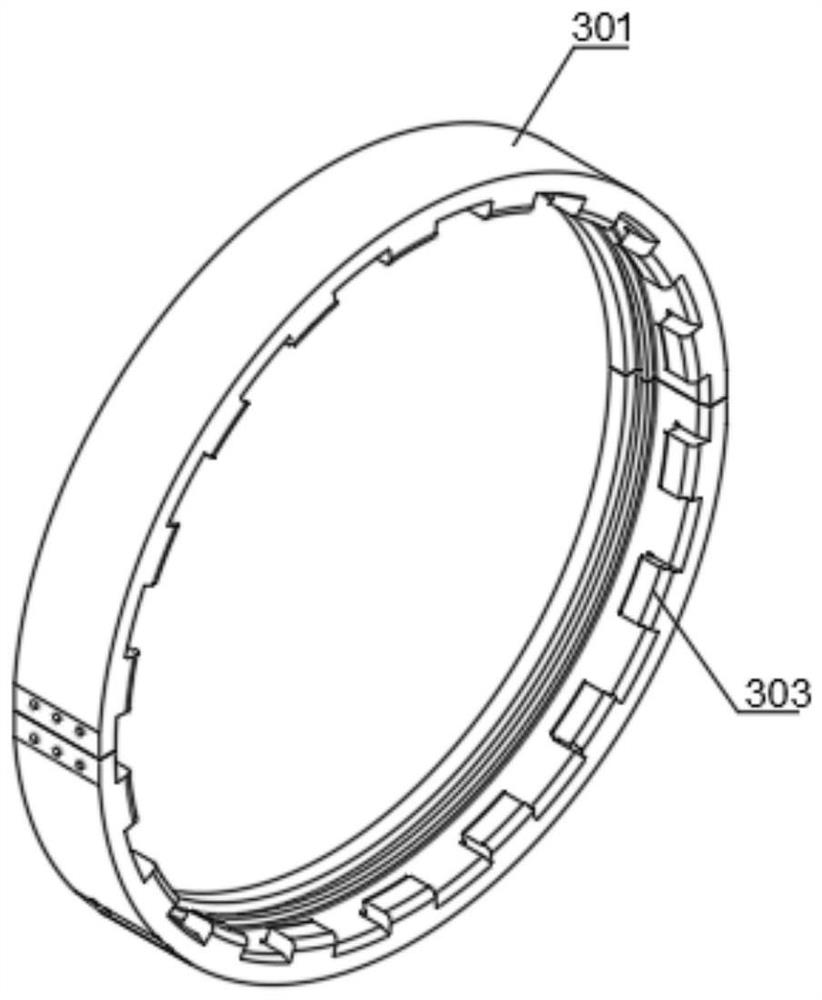

[0035] like Figure 1-10 As shown, the present invention provides a robot hydrostatic pressure test device, which is characterized in that it includes a tank 1, a tank cover 2 is hinged on the tank 1, and the tank cover 2 is reversibly covered on the tank 1 , the side wall of the silo 1 is fixedly connected with an overturn base 101, one end of the overturn base 101 is hinged with a flip oil cylinder 102, and the other end is hinged with a bent flip arm 103, and one end of the bent flip arm 103 is connected to the flip oil cylinder 102. The other end is hinged, and the other end of the bent cover arm 103 is hinged to the cylinder cover 2 . Both the upper edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com