A large-scale underwater explosion damage test system and method

A technology of underwater explosion and test system, which is applied in the field of theoretical analysis of underwater explosion and damage. The effect of error and safety universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

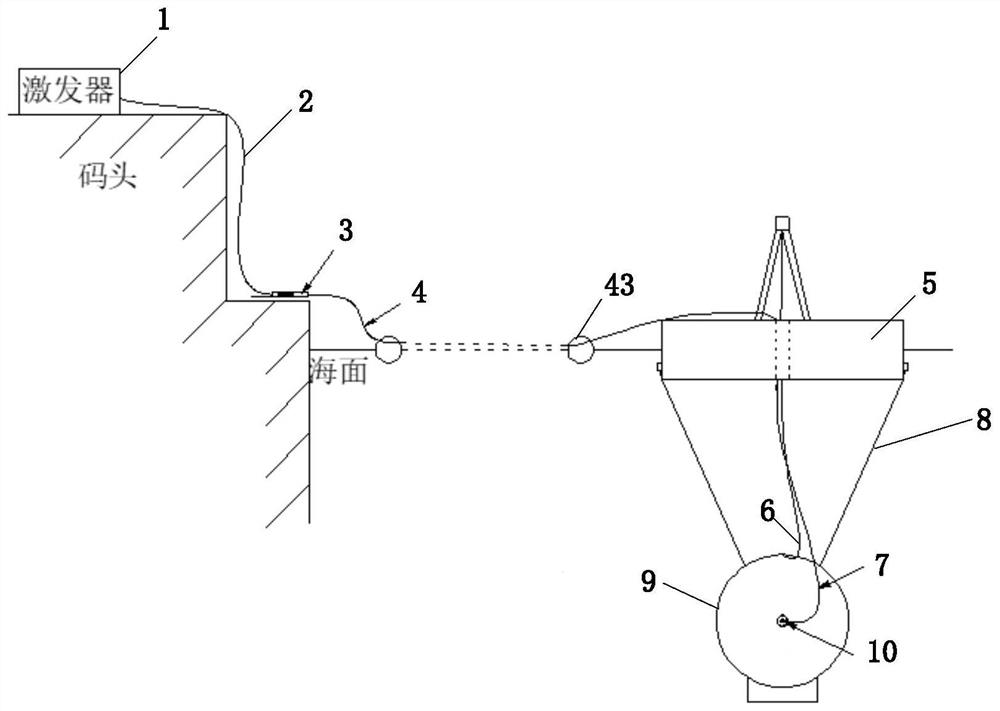

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

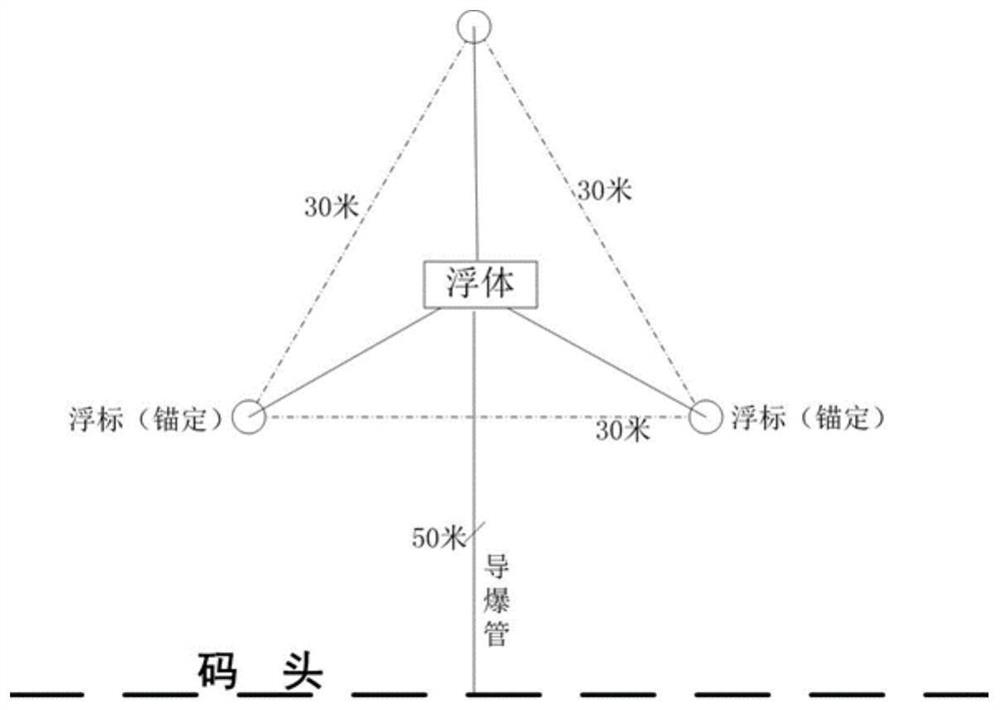

[0035] The present invention provides a large-scale underwater explosion damage test scheme, which proposes solutions to several prominent problems in the prior art, specifically including:

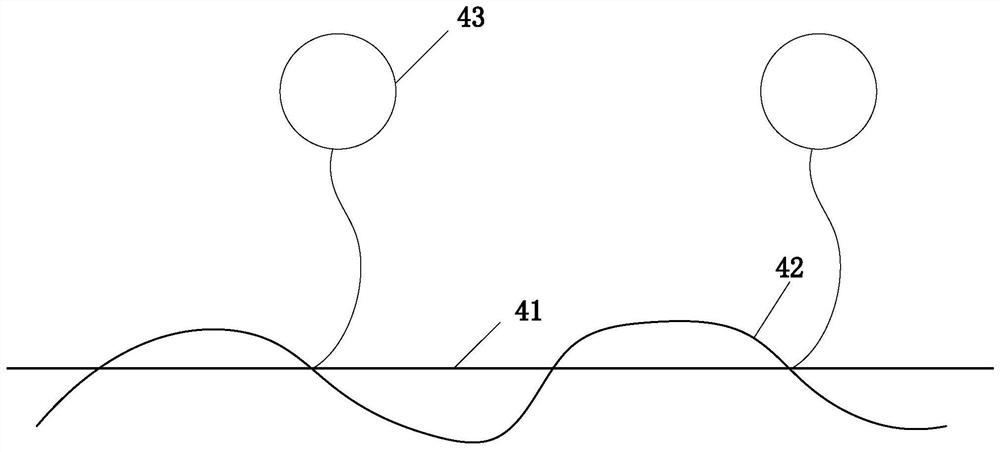

[0036] (1) During the test process, it is necessary to push the detonating tube to the detonation position on the water surface. The detonating tube is directly subjected to force and is easily damaged, which may cause a delay in detonation time or even failure to detonate, which has a negative effect on the completion and accuracy of the test. influences. Aiming at this problem, the present invention connects a strengthening cable to the detonating tube, replaces the detonating tube to be directly stressed during laying and dragging, thereby playing a protective role, and at the same time connects a floating ball to prevent sinking.

[0037] (2) There is no fixation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com