Gas turbine compressor casing anti-surge structure and surge margin evaluation method thereof

A gas turbine, surge margin technology, applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of small increase in the axial velocity of the exhaust section and small air intake in the intake section, and achieve Reduce the effect of increasing the air volume, improving the flow state, and reducing the angle of attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

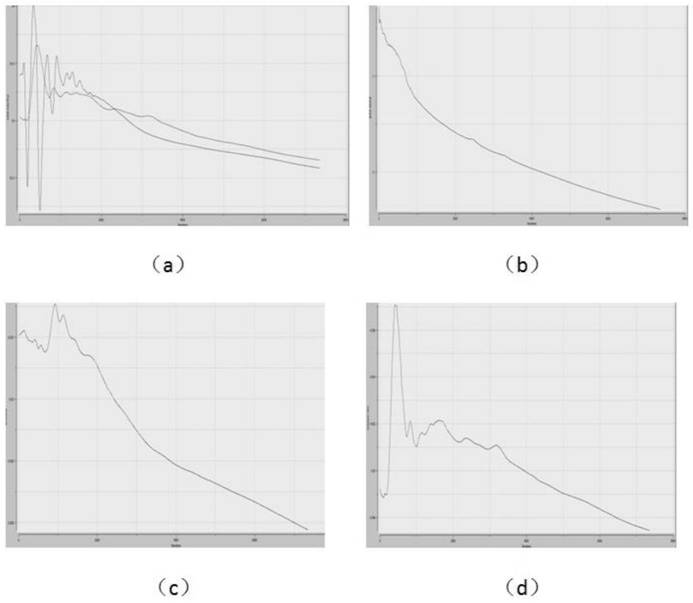

[0088] The main function of the treatment of the compressor case is to reduce the flow rate at the stall point, thereby increasing the surge margin of the compressor. In this embodiment, the analysis and calculation of the treatment case of the prototype machine are carried out to analyze the treatment of different structural forms of the case. The performance effect is evaluated by taking the surge margin improvement as the evaluation index of the casing handling performance:

[0089] In the formula, π and G represent the total pressure ratio and flow rate, respectively, and the subscripts s and 0 represent the near-stall point and working point of the casing, respectively;

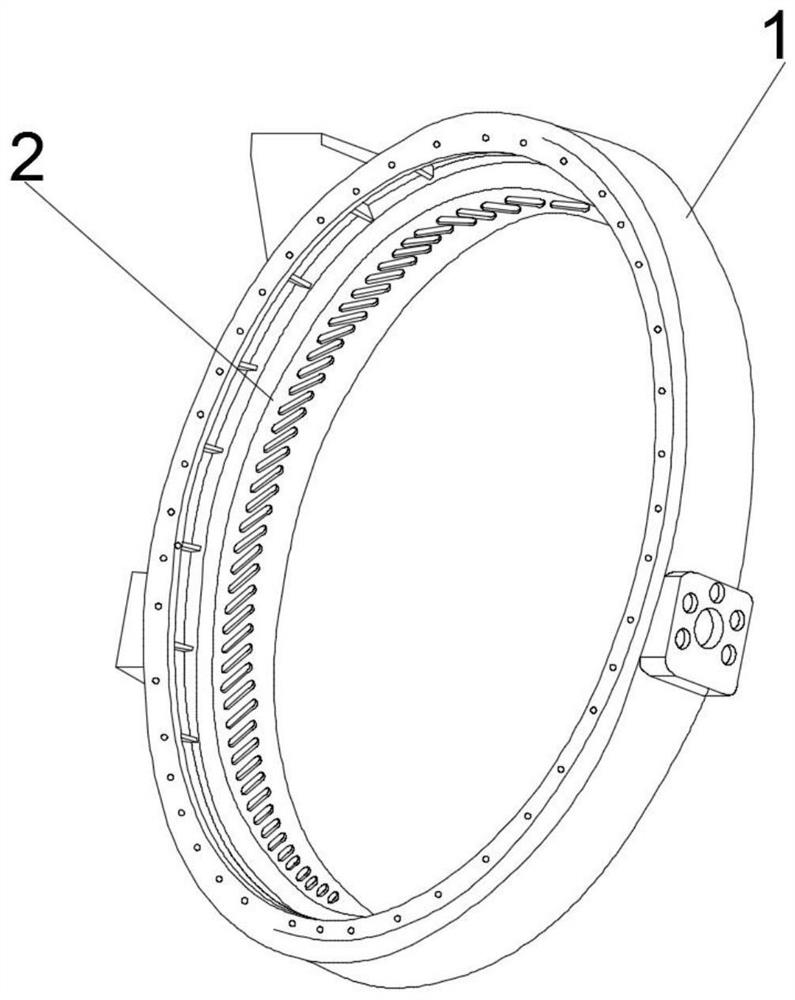

[0090]In order to calculate the surge margin of the above-mentioned case processing expansion stability structure, this embodiment designs a method for evaluating the surge margin of the anti-surge structure of the gas turbine compressor casing, and the anti-surge structure of the gas turbine compressor...

Embodiment 2

[0127] Example 2: Calculate the result value of Y+ value and detect y + Whether the value of is between 0 and 10, judge the feasibility of the grid division method in Step 2 of this evaluation method:

[0128] (1) The calculation results show that most of the area y on the wall surface of this method + + <5, the total number of three-dimensional grids of the impeller group is 18 million, and the total number of grid blocks is 221. After the grid quality inspection, the grid parameters are all within the reasonable value range. The inspection results are as follows:

[0129] Table 1.1 3D Mesh Quality Check

[0130]

[0131] (2) further calculate the result value of the Y+ value of the method for gas turbine compressor casing anti-surge structure surge margin of the present invention to calculate, whether the value of detection y+ is between 0~10, judge the feasibility of this evaluation method: pass Figure 10 It can be seen from the Y+ value distribution cloud diagram sh...

Embodiment 3

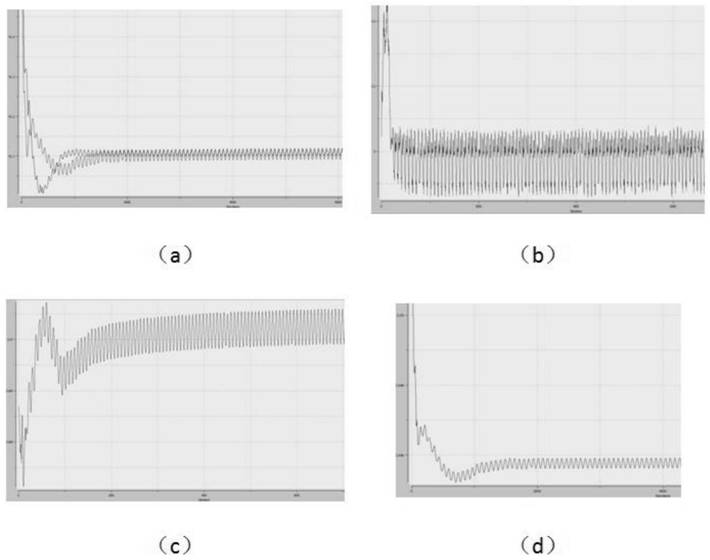

[0132] Embodiment 3: After calculating the surge margin of the compressor working under the design working conditions in step S402 of Embodiment 1, it also includes using the Y+ value distribution, entropy increase distribution and relative Mach number distribution for the evaluation method. Feasibility further verification process, including:

[0133](1) calculate for the result value of Y+ value, concrete process and result are as shown in above-mentioned embodiment 2 (as Figure 10 shown), it proves that this evaluation method meets the calculation requirements;

[0134] (2) Utilize the parameter setting described in this method to simulate the result value of entropy distribution, as can be seen, when the meridian flow surface, casing processing and meridian flow channel area in the calculation domain divided by the present invention are working, Such as Figure 12 As shown, all of them produced entropy increase, through Figure 12 It can be seen from the simulation res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com