Stone-like paint prepared from flexible colored particles and preparation process thereof

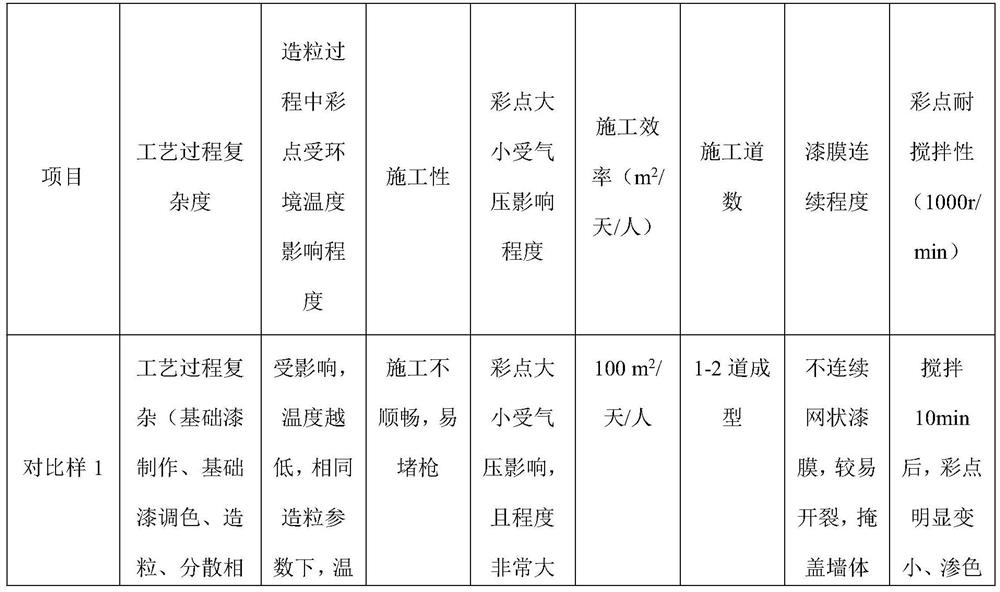

A technology of imitating stone paint and color particles, applied in the field of paint production, can solve the problems of low difficulty of production process, complicated granulation process, low construction efficiency, etc., and achieves improved stability and overall performance, low difficulty of production process, and improved production efficiency. Effect of drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

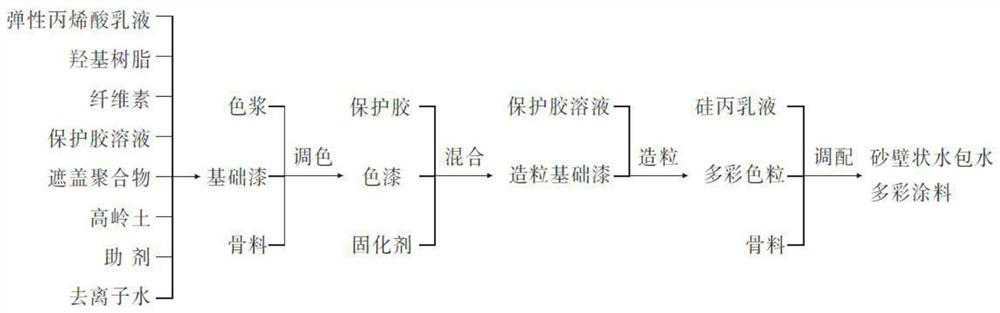

Method used

Image

Examples

Embodiment 1

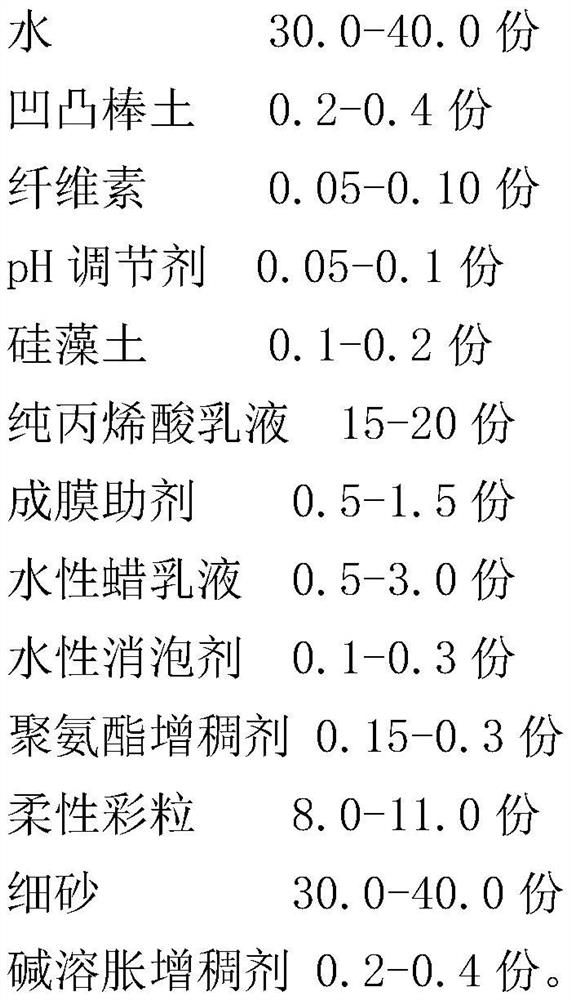

[0055] The imitation stone paint prepared by using flexible color particles according to the present invention is mainly prepared from the following components according to the following weight and part ratios:

[0056] 35 parts of water

[0057] Attapulgite 0.3 parts

[0058] Cellulose 0.08 parts

[0059] pH adjuster 0.08 parts

[0060] Diatomaceous earth 0.15 parts

[0061] Pure acrylic emulsion 18 parts

[0062] Coalescing aid 0.8 parts

[0063] Water-based wax emulsion 2.6 parts

[0064] Water-based defoamer 0.2 parts

[0065] Polyurethane thickener 0.21 parts

[0066] 9 pieces of flexible color particles

[0067] 35 parts fine sand

[0068] Alkali swelling thickener 0.3 part.

[0069] The preparation method of the imitation stone paint prepared by adopting flexible colored particles comprises the following steps carried out in sequence:

[0070] 1) Slowly add attapulgite to the water, and fully disperse at a speed of 900rpm for 4 minutes; then add cellulose and...

Embodiment 2

[0075] The imitation stone paint prepared by using flexible color particles according to the present invention is mainly prepared from the following components according to the following weight and part ratios:

[0076] 30.0 parts of water

[0077] Attapulgite 0.4 parts

[0078] Cellulose 0.05 part

[0079] pH adjuster 0.1 parts

[0080] Diatomaceous earth 0.1 parts

[0081] Pure acrylic emulsion 20 parts

[0082] Coalescing aid 0.5 parts

[0083] Water-based wax emulsion 3.0 parts

[0084] Water-based defoamer 0.1 part

[0085] 0.3 parts of polyurethane thickener

[0086] Flexible color particles 8.0 parts

[0087] Fine sand 40.0 parts

[0088] Alkali swelling thickener 0.2 part.

[0089] The flexible color particles are formed by mixing the following solid latex films with different diameters according to the following weight ratio: 0.5 parts of a solid latex film with a diameter of 8 mm, 2 parts of a solid latex film with a diameter of 4 mm, 5.5 parts of a solid ...

Embodiment 3

[0098] The imitation stone paint prepared by using flexible color particles according to the present invention is mainly prepared from the following components according to the following weight and part ratios:

[0099] 40.0 parts of water

[0100] Attapulgite 0.2 parts

[0101] Cellulose 0.10 parts

[0102] pH adjuster 0.05 parts

[0103] Diatomaceous earth 0.2 parts

[0104] Pure acrylic emulsion 15 parts

[0105] Coalescing aid 1.5 parts

[0106] Water-based wax emulsion 0.5 parts

[0107] 0.3 parts of water-based defoamer

[0108] Polyurethane thickener 0.15 part

[0109] Flexible color particles 11.0 parts

[0110] Fine sand 30.0 parts

[0111] Alkali swelling thickener 0.4 part.

[0112] The attapulgite is hydrated magnesium aluminum silicate, the water-based wax emulsion is anion-modified paraffin wax emulsion, the polyurethane thickener is a hydrophobic modified polyurethane thickener, and the alkali-swellable thickener is a hydrophobic modified An alkali-sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com