Method and application of modified iron phosphate and steel pickling waste liquid for preparing modified iron phosphate

A technology of pickling waste liquid and iron phosphate, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficult to meet the standards of various indicators, waste, and difficult post-processing, etc., and achieve excellent capacity performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

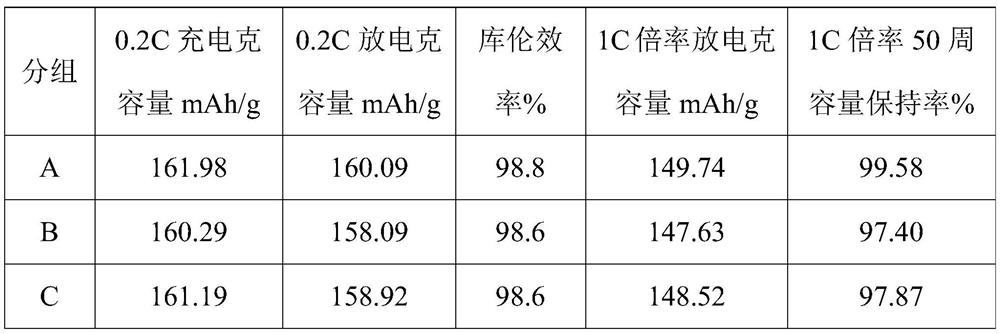

Examples

Embodiment 1

[0024] A method for preparing modified iron phosphate from steel pickling waste liquid, comprising the following steps:

[0025] S1. Transfer the pickling waste liquid of the steel into a treatment tank with a double-layer grid for filtration to obtain a filtrate A, pass the filtrate A into the oxidation tank, add titanium dioxide, and irradiate the Fe for 1.5 hours with sunlight. 2+ Completely oxidized to Fe 3+ , then add phosphoric acid, then add urea to adjust pH=2.7, react at 50°C for 2h, filter to obtain filtrate B and filter cake (that is, crude iron phosphate), wherein titanium dioxide and Fe in filtrate A 2+ The molar ratio of 1:18, phosphoric acid and Fe in filtrate A 2+ The molar ratio is 1:1;

[0026] S2. The filtrate B is concentrated and recovered to obtain hydrochloric acid, then the crude ferric phosphate is dissolved in hydrochloric acid, urea is added to adjust pH=3.0, the reaction is carried out at 65° C. for 1 h, the filter cake is collected by filtration,...

Embodiment 2

[0028] A method for preparing modified iron phosphate from steel pickling waste liquid, comprising the following steps:

[0029] S1. Transfer the pickling waste liquid of the steel into a treatment tank with a double-layer grid for filtration to obtain a filtrate A, pass the filtrate A into the oxidation tank, add titanium dioxide, and irradiate the Fe for 2 hours with sunlight. 2+ Completely oxidized to Fe 3+ , then add phosphoric acid, then add urea to adjust pH=3.0, react at 60 ° C for 2.5h, filter to obtain filtrate B and filter cake (that is, crude iron phosphate), wherein, titanium dioxide and Fe in filtrate A 2+ The molar ratio of 1:25, phosphoric acid and Fe in filtrate A 2+ The molar ratio is 1.05:1;

[0030] S2. The filtrate B is concentrated and recovered to obtain hydrochloric acid, then the crude ferric phosphate is dissolved in hydrochloric acid, urea is added to adjust pH=4.0, the reaction is carried out at 75° C. for 2 h, the filter cake is collected by filtr...

Embodiment 3

[0032] A method for preparing modified iron phosphate from steel pickling waste liquid, comprising the following steps:

[0033] S1. Transfer the pickling waste liquid of the steel into a treatment tank with a double-layer grid for filtration to obtain filtrate A, pass the filtrate A into the oxidation tank, add titanium dioxide, and irradiate the Fe for 3 hours with sunlight. 2+ Completely oxidized to Fe 3+ , then add phosphoric acid, then add urea to adjust pH=3.8, react at 70°C for 3.5h, filter to obtain filtrate B and filter cake (that is, crude iron phosphate), wherein titanium dioxide and Fe in filtrate A 2+ The molar ratio of 1:30, phosphoric acid and Fe in filtrate A 2+ The molar ratio of 1.07:1;

[0034] S2. The filtrate B is concentrated and recovered to obtain hydrochloric acid, then the crude iron phosphate is dissolved in hydrochloric acid, urea is added to adjust pH=5.0, the reaction is carried out at 80°C for 2.5h, the filter cake is collected by filtration, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com