Lifting working ladder driven by air source power

A power-driven, working ladder technology, applied in lifting frames, lifting devices, etc., can solve problems such as electric sparks and high-power motors that are easy to generate heat, so as to improve work efficiency, improve stability and wind resistance, and strengthen The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described and understood by non-limiting examples below.

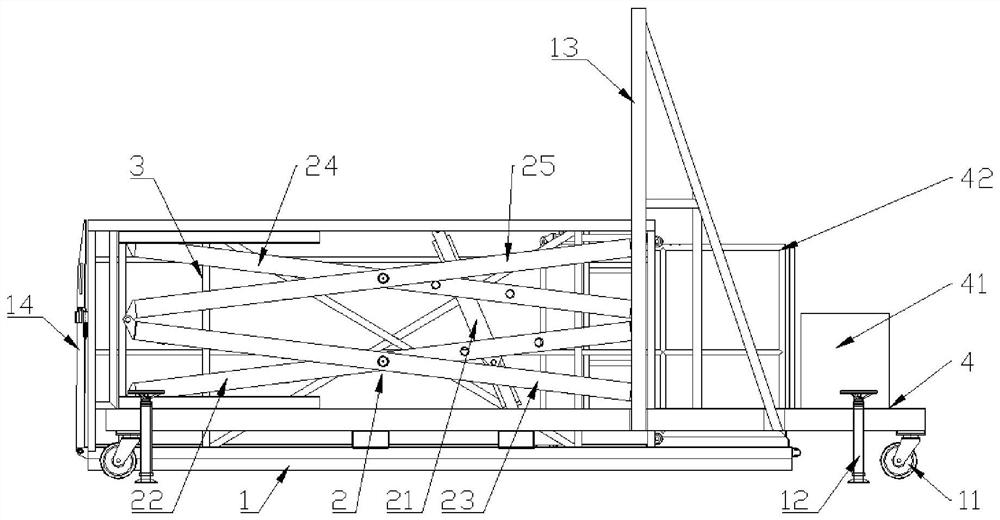

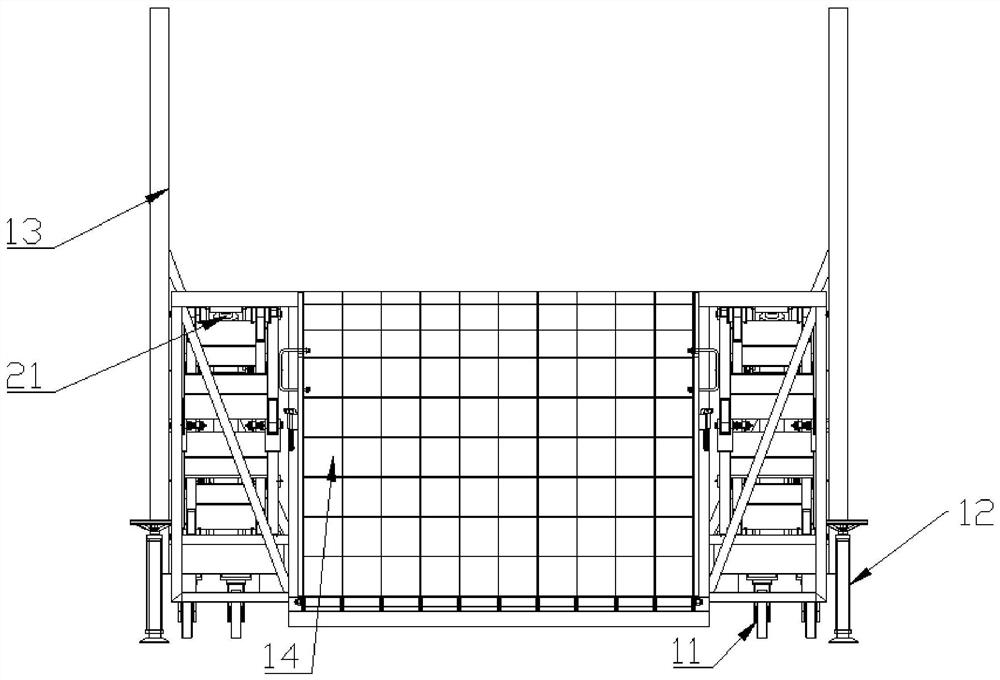

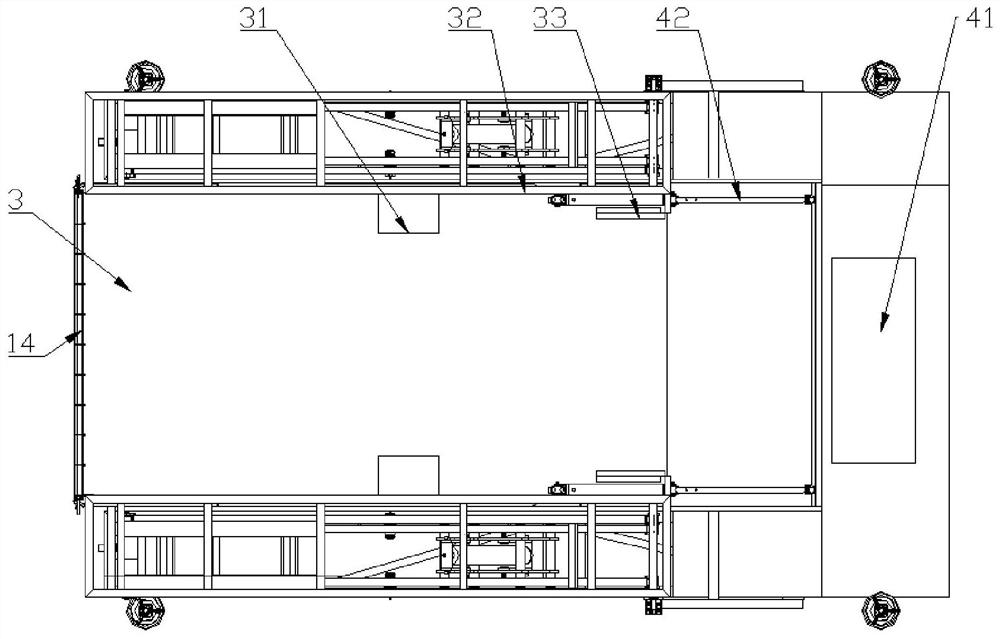

[0017] like Figure 1-3 As shown, the present invention is an air-source power-driven lift working ladder, which includes a bottom frame 1, which is designed to stick to the ground and has a height above the ground of 80 mm. The top of the bottom frame 1 passes through scissor lifting mechanisms on both sides. 2. The support is equipped with an aluminum lifting platform 3. Compared with the scissor lifting mechanism 2 in the prior art, it is directly arranged under the lifting platform. The design of the supports on both sides strengthens the stability of the platform. The bottom frame 1 and the scissor lifting mechanism 2 Using Q345B material, it has the characteristics of high strength and light specific gravity;

[0018] The scissor lifting mechanism 2 includes a first scissor bar 22 hinged on the top of the bottom frame 1 through a hinge seat, a third scissor bar 24 hinged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com