Locking device for battery box and body connection structure of battery box

A locking device and box body technology, applied in the field of auto parts, can solve the problems of vibration noise and service life defects of the snap-on locking method, and achieve the effects of shortening the quick change time, facilitating processing and improving the quality of the quick change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

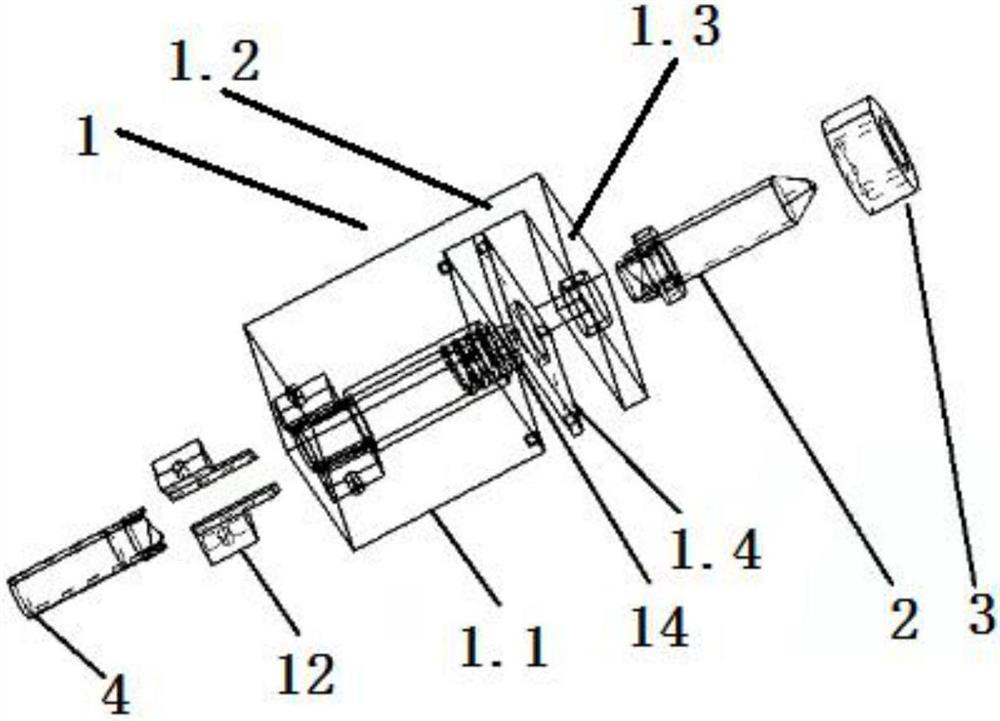

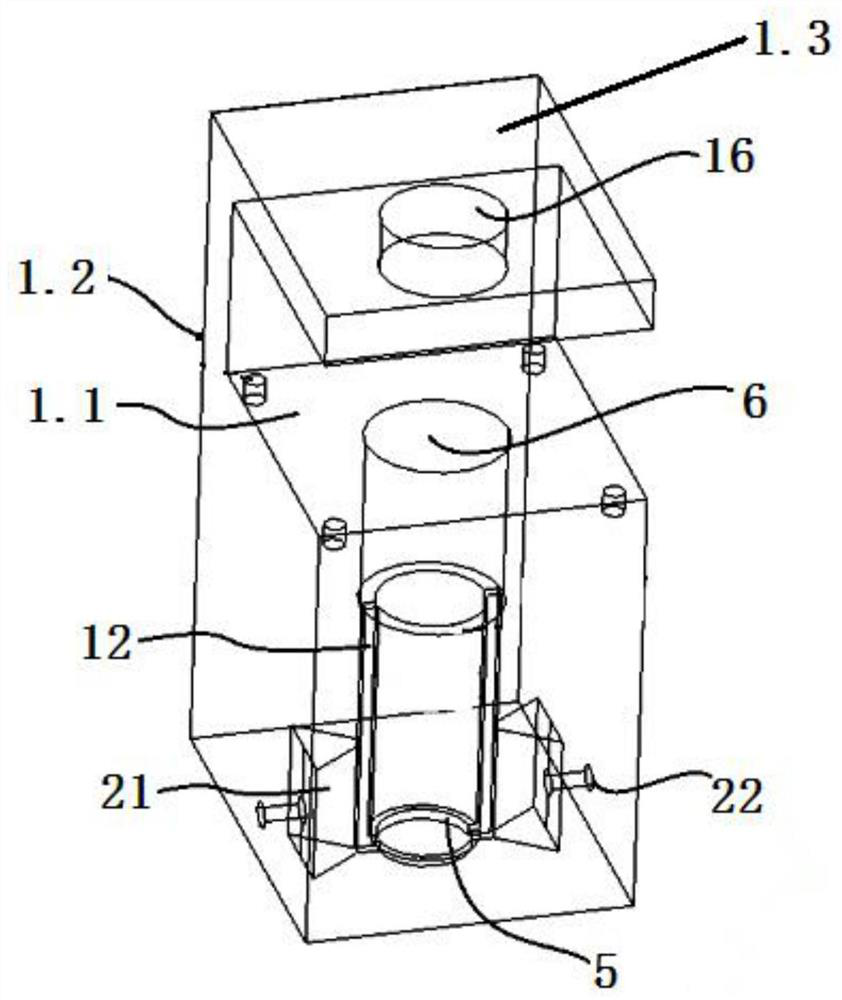

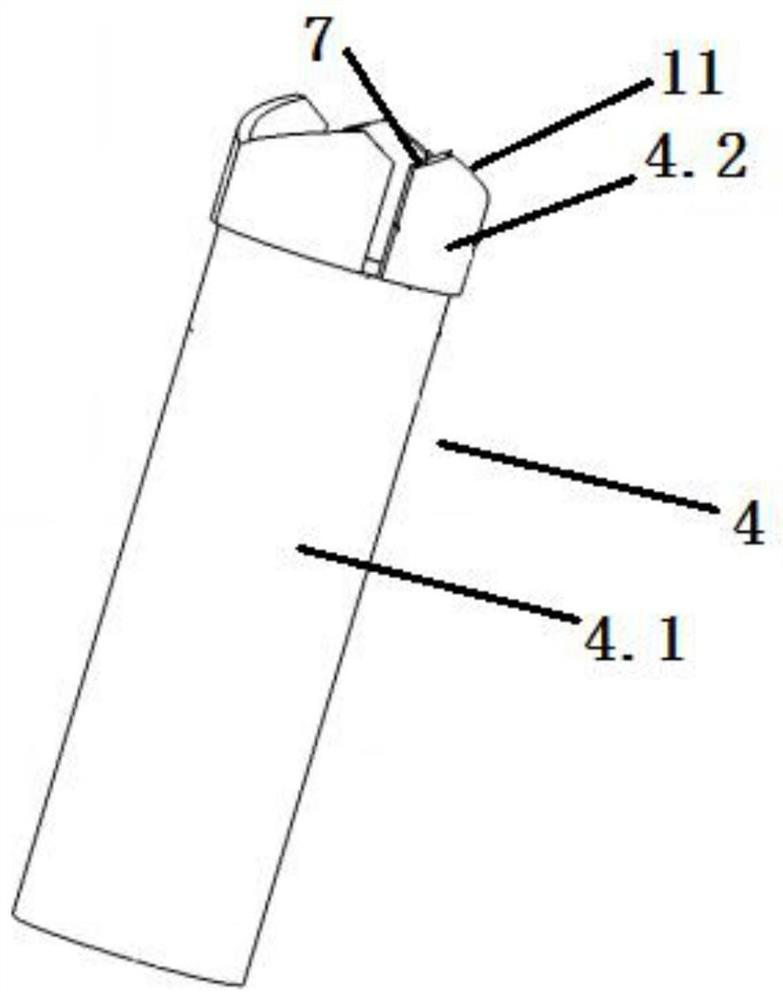

[0029] Such as figure 1 - The locking device for the battery box shown in 11, including the telescopic sleeve 1, the telescopic pin 2 arranged in the telescopic sleeve 1, the telescopic sleeve 1 that can be inserted, and the fixed sleeve 3 that cooperates with the telescopic pin 2 and is fixed in the telescopic sleeve 1 , the telescopic sleeve 1 is provided with a pressing rod 4 that can drive the telescopic pin 2 to move axially into the fixed sleeve 3, and the telescopic sleeve 1 is provided with a column component that can keep the telescopic pin 2 at the matching position with the fixed sleeve 3 , A resetting part that can make the telescopic pin 2 withdraw from the fixed sleeve 3 is connected between the telescopic pin 2 and the telescopic sleeve 1 .

[0030] The telescopic sleeve 1 includes a telescopic sleeve base 1.1, a teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com