Zip-top can recycling method

A technology of recycling and cans, which is applied in the direction of furniture waste recycling, recycling technology, cleaning methods and utensils, can solve the problems of incomplete cutting of easy-cut cans, inability to cut cans, and different cans, so as to avoid direct collision and improve use Longevity, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

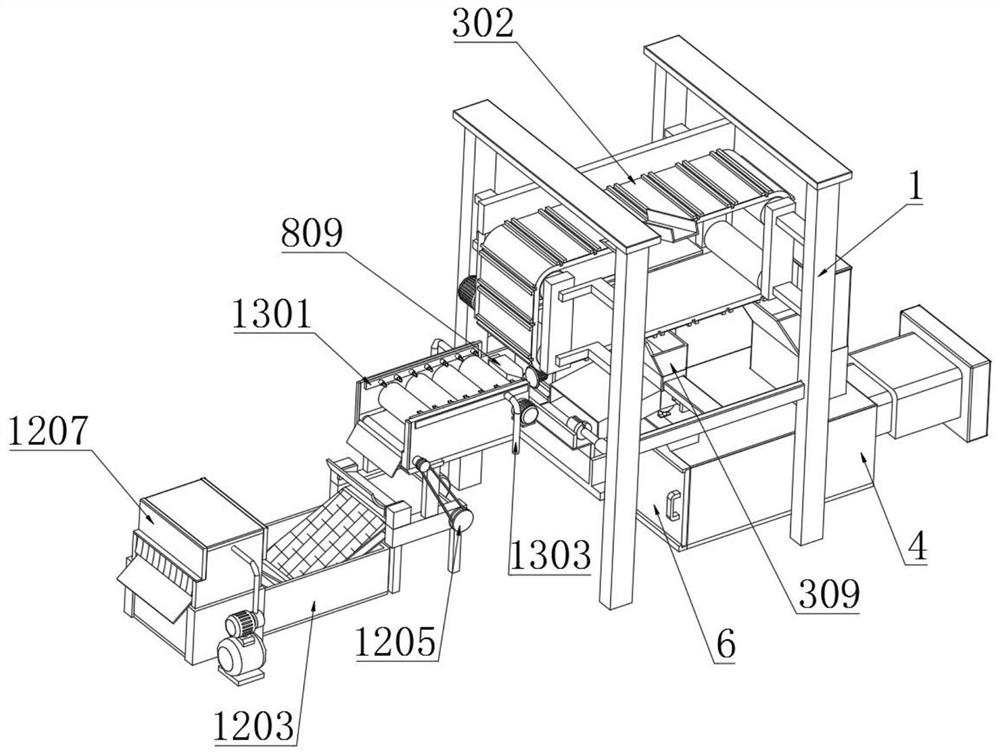

[0045] Example: such as Figure 2-11 As shown, the present invention provides a technical solution, a method for recycling and processing pop cans. One end of the top of the frame body 1 is fixedly equipped with a feeding slide 2, and the top of the frame body 1 is fixedly mounted with a sorting mechanism 3. sort;

[0046] The sorting mechanism 3 comprises a rotating shaft 301, crawler belts 302, a rotating motor 303, a partition bar 304, a magnetic adsorption block 305, an anti-skid baffle 306, an aluminum tank channel 307, an anti-off plate 308, an iron tank channel 309 and a tank Body limit baffle 310;

[0047] The top of the frame body 1 is symmetrically fixed with a rotating shaft 301, and the middle part of the rotating shaft 301 is sleeved with a crawler belt 302, and one end of a rotating shaft 301 is fixedly connected with a rotating motor 303, and the surface of the crawler belt 302 is equidistantly fixedly installed with a partition strip 304, and the crawler belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com