Safety belt hanging bracket

A technology for hanging brackets and safety belts, which is applied to safety belts and life-saving equipment, etc., which can solve the problems that workers are inconvenient to move and work, and achieve the effects of increasing the scope of application, moving smoothly and stably, and facilitating operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

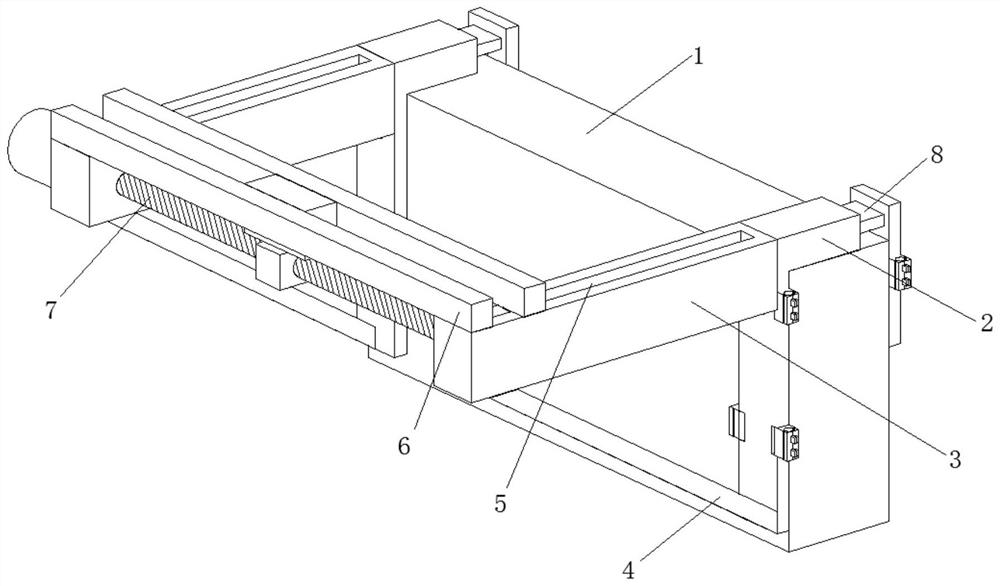

[0033] A seat belt suspension bracket such as Figure 1-Figure 6 As shown, including the wall 1, the surface of the wall 1 is connected with two support blocks 2 by bolts, the front parts of the two support blocks 2 are welded with a connection block 3, and a support is welded between the connection block 3 and the support block 2 Rod 4, the upper surface of connecting block 3 is provided with slide rail 5, and the inner wall of slide rail 5 is slidingly connected with two limiting plates 6, and the lower surface of limiting plate 6 is slidingly connected with the upper surface of connecting block 3, two A transmission mechanism 7 is arranged between the connecting blocks 3 , and a fixing mechanism 8 is arranged at the rear of the support block 2 .

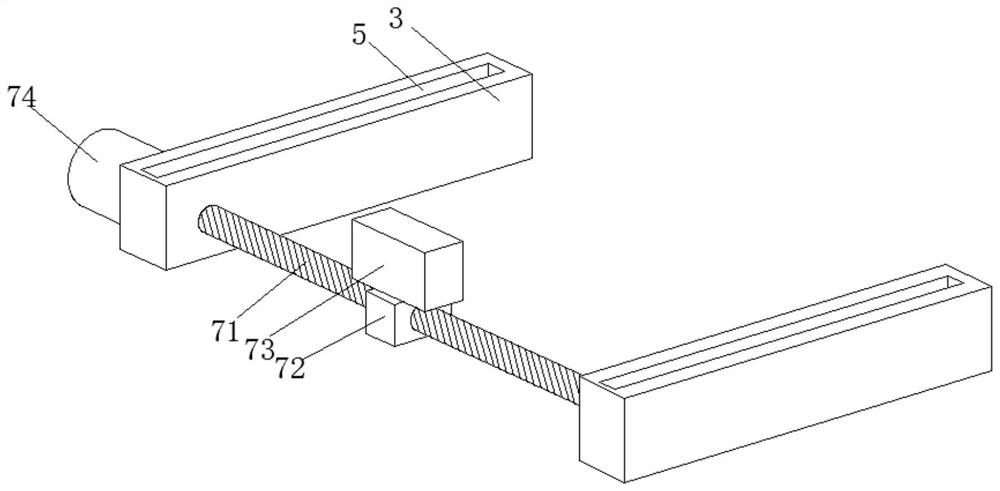

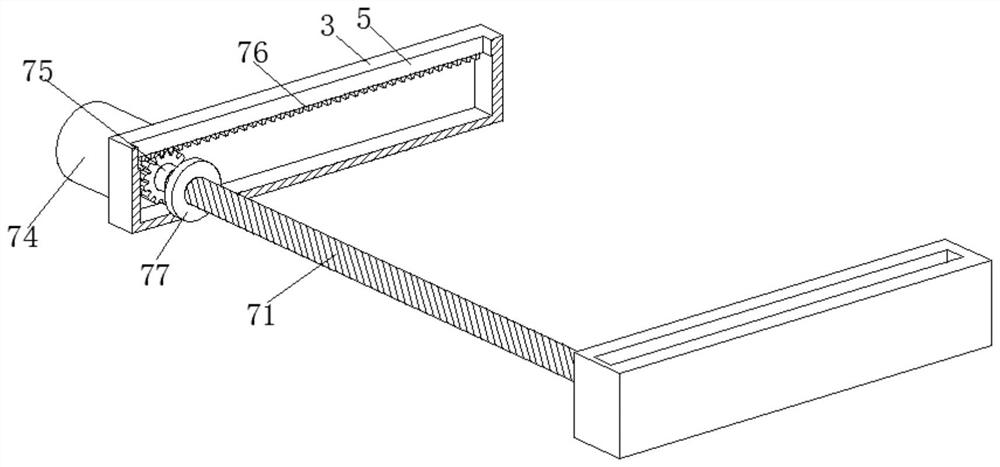

[0034] In this embodiment, the transmission mechanism 7 includes a screw rod 71, the surface of the screw rod 71 is threadedly connected with a moving block 72, the top of the moving block 72 is welded with a limit block 73, and t...

Embodiment 2

[0040] Such as Figure 5-Figure 7 As shown, the surface of the connecting plate 81 is slidingly connected with the inner wall of the support block 2, the rear end of the tension spring 84 is welded and fixed with the inner wall of the support block 2, and the front part of the fixed plate 82 is connected to the rear part of the body of wall 1 by bolts. The tension spring 84 will pull the connecting plate 81, so that the fixed plate 82 at the rear of the connecting plate 81 and the support block 2 tightly clamp the wall 1, which is convenient for workers to fix and install it with bolts, and reduces the workman's work. Labor intensity also increases the efficiency of installation.

[0041] It is worth noting that the installation device 83 includes a fixed block 831, the inner wall of the fixed block 831 is rotatably connected with a rotating shaft 832, the right side of the fixed block 831 is respectively rotatably connected with two rotating plates 833, and the right side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com