Camshaft, and method for the production of a camshaft

A technology of camshafts and sliding cams, which is applied in the field of manufacturing camshafts, can solve problems such as damage to axial displacement, and achieve the effects of simple device, easy manufacture, and good axial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

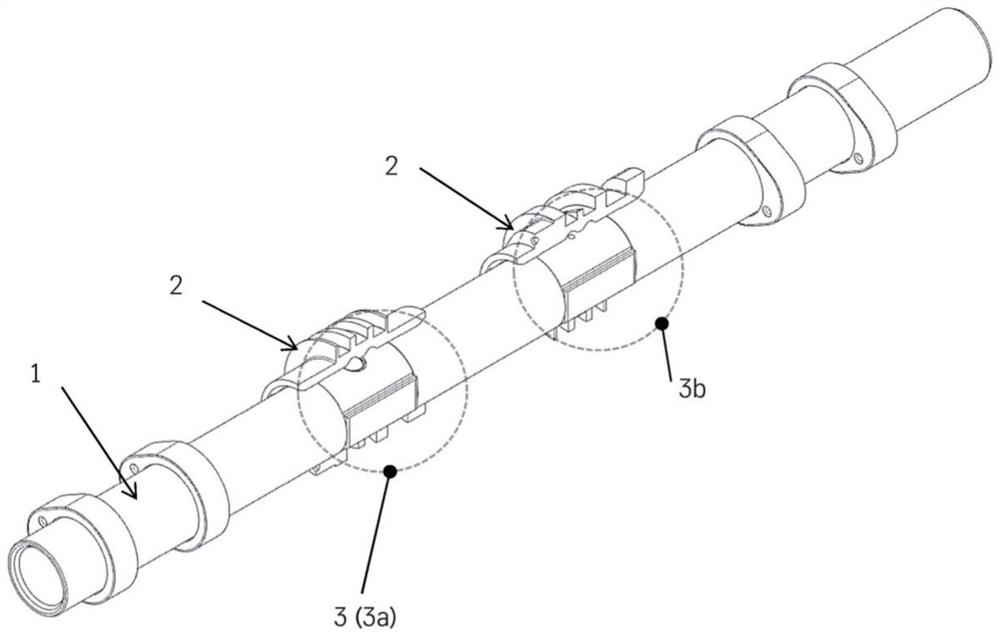

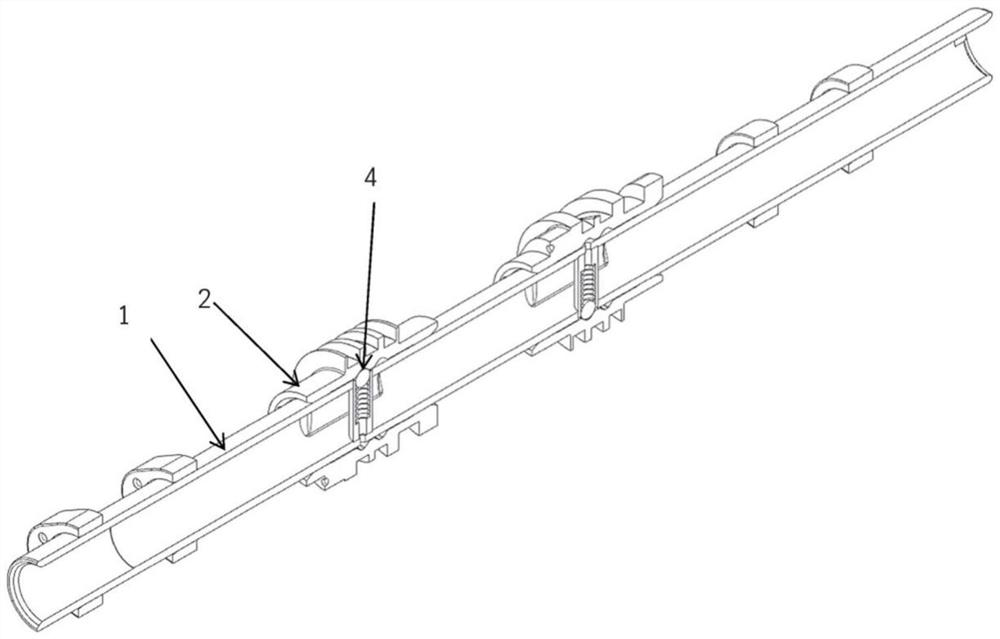

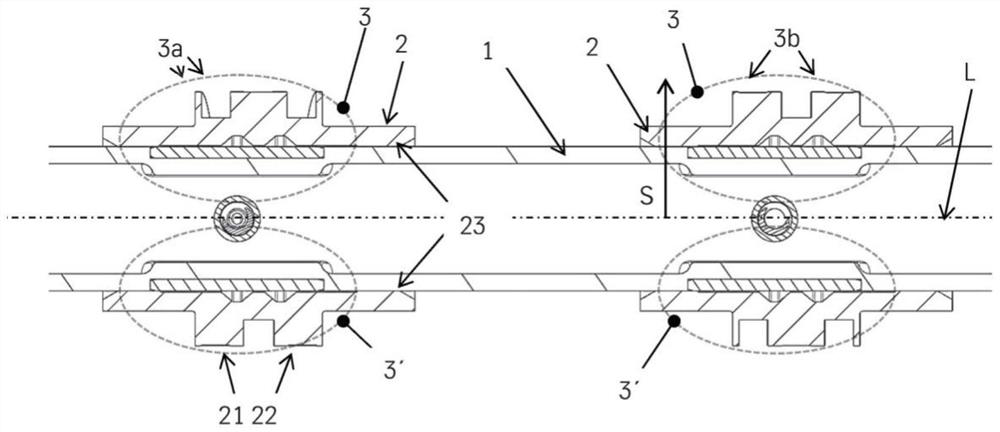

[0043] first reference figure 1 .

[0044] The camshaft according to the invention essentially comprises a shaft 1 and at least one sliding cam assembly 2 . The sliding cam assembly 2 is arranged on the shaft 1 in a rotationally fixed but axially movable manner. Arranged between the shaft 1 and the sliding cam assembly 2 is a device 3 for preventing rotation, wherein the device 3 for preventing rotation has a recess 33 facing the shaft 1 in the sliding cam assembly 2 and a sliding facing in the shaft 1 The flat portion 31 of the cam assembly and the intermediate element 32 arranged between the flat portion 31 and the notch 33 .

[0045] The shaft 1 is preferably designed as a hollow shaft with a circular cross section. The shaft 1 has a longitudinal axis L or an axis of rotation. Axis 1 can be equipped with other accessories and functional parts such as fixed cams, needle bearings, bearing rings, sensor wheels and ends.

[0046] The sliding cam assembly 2 preferably compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com