Full-face tunnel boring machine multifunctional cutterhead suitable for complex stratums

A technology for tunnel boring machines and complex strata, which is applied in the field of multifunctional cutterheads for full-face tunnel boring machines. Effects of maintenance and prevention of abnormal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Embodiment: A multifunctional cutterhead of a full-section tunnel boring machine adapted to complex formations, which can realize different cutter spacing, different cutter height difference cutter arrangements, and the installation of cutters of different sizes, and provides full-face tunnel boring machines with a complex adaptability. The cutter head of the formation is simple and effective in use and easy to operate.

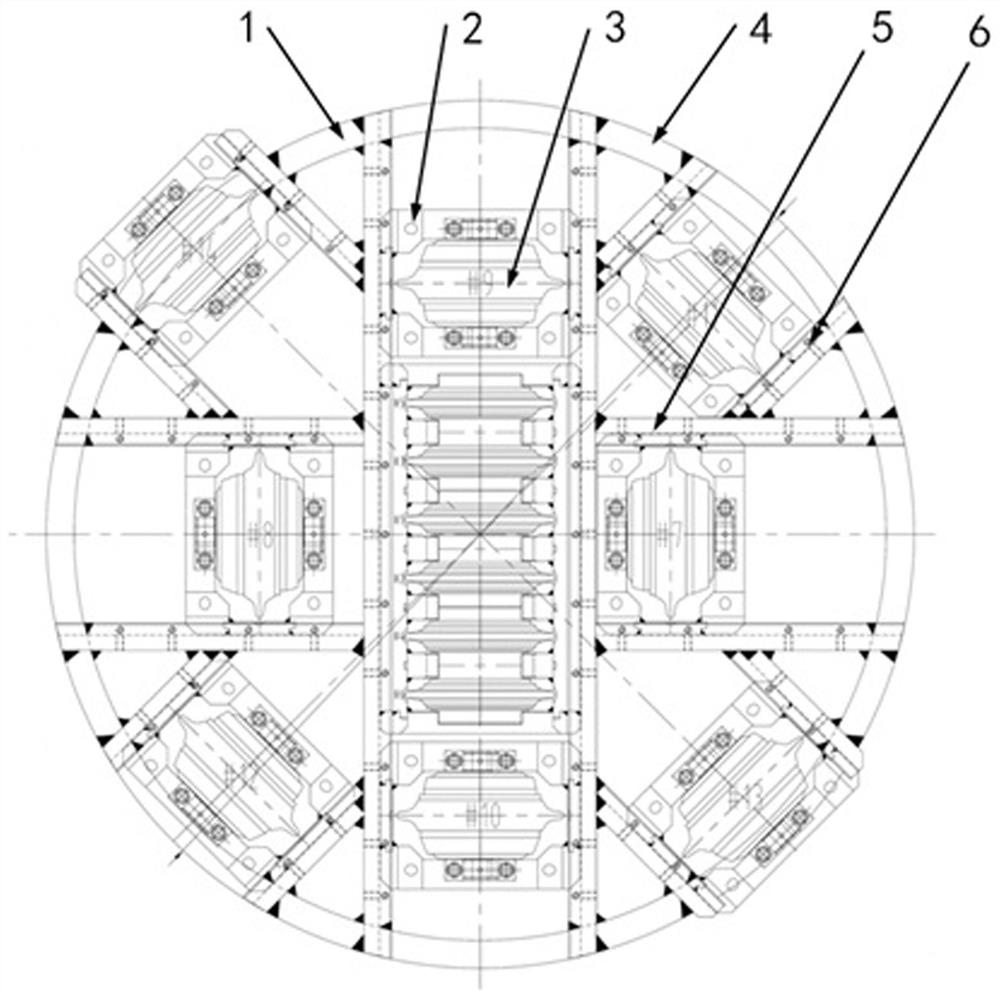

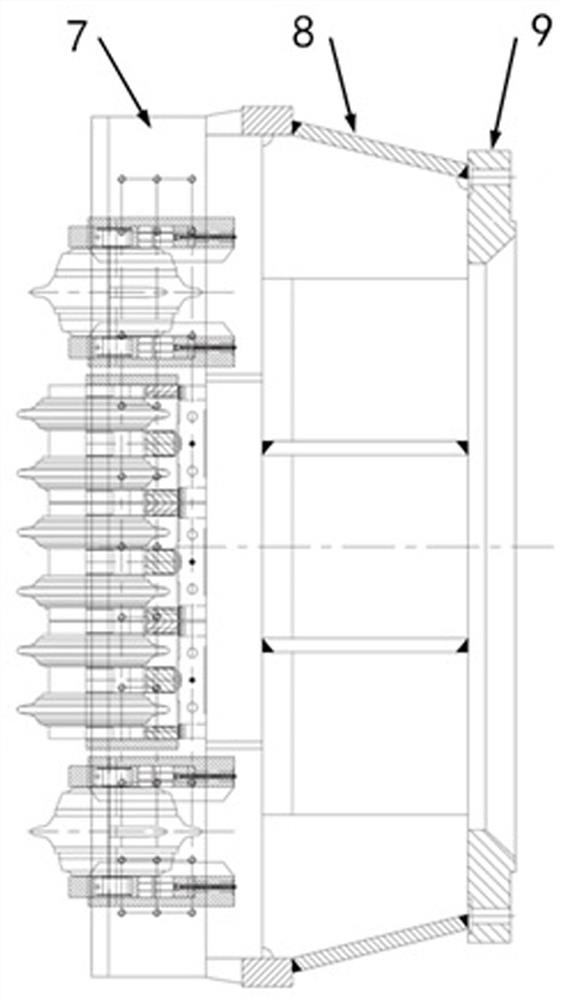

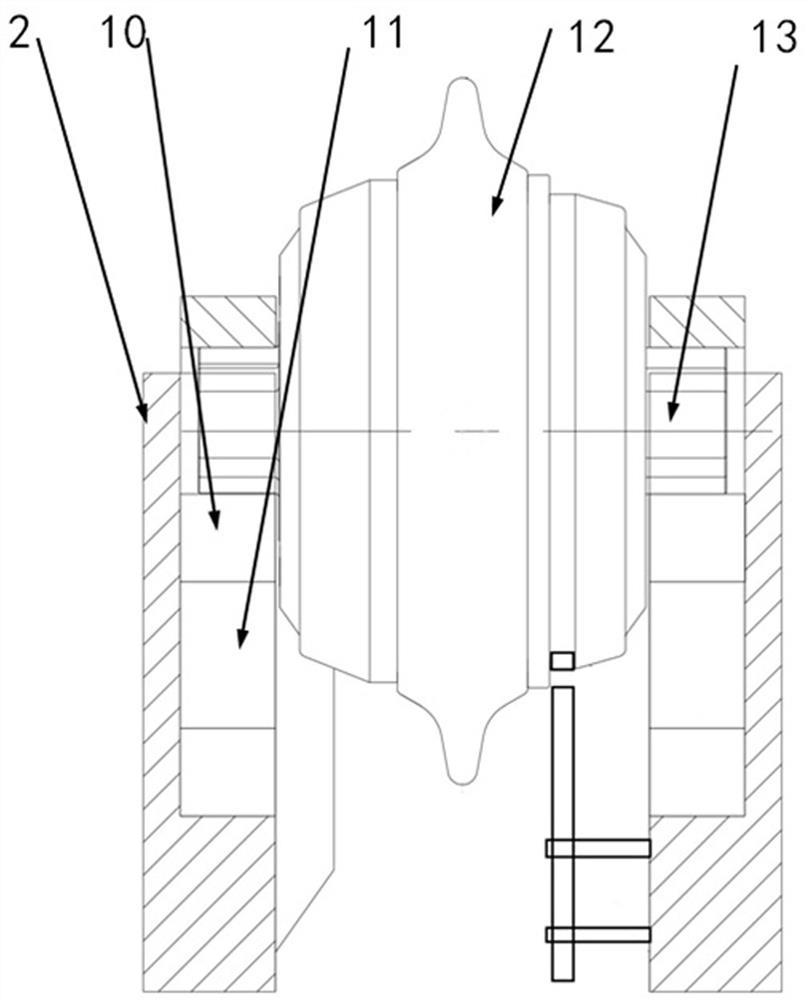

[0028] Such as figure 1 , figure 2 As shown, it includes a cutter head body 1, several tool holders 2 that are movably installed on the cutter head body 1, and a tool 3 installed on the cutter holder 2; the cutter head body 1 includes a flange 9, a cutter head panel 7, and welding The connecting rib 8 between the circumference of the flange 9 and the cutterhead panel 7, the cutterhead panel 7 includes the ring beam 4 welded together with the outer ring of the connecting rib 8 and the Pozi-shaped knife welded on the ring beam 4 Beam 5, on the opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com