Gas injection method in thermal recovery process

A thermal recovery and nitrogen technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., which can solve the problems of multiple operations and short effective period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

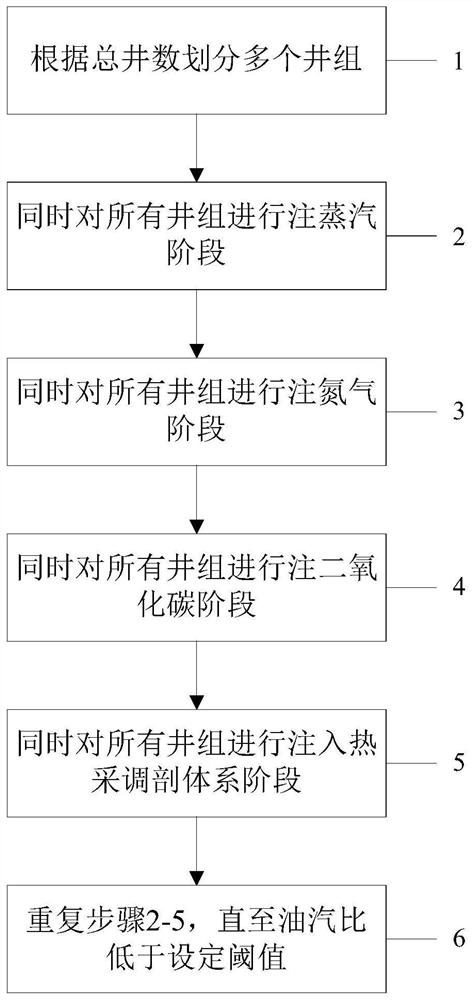

Method used

Image

Examples

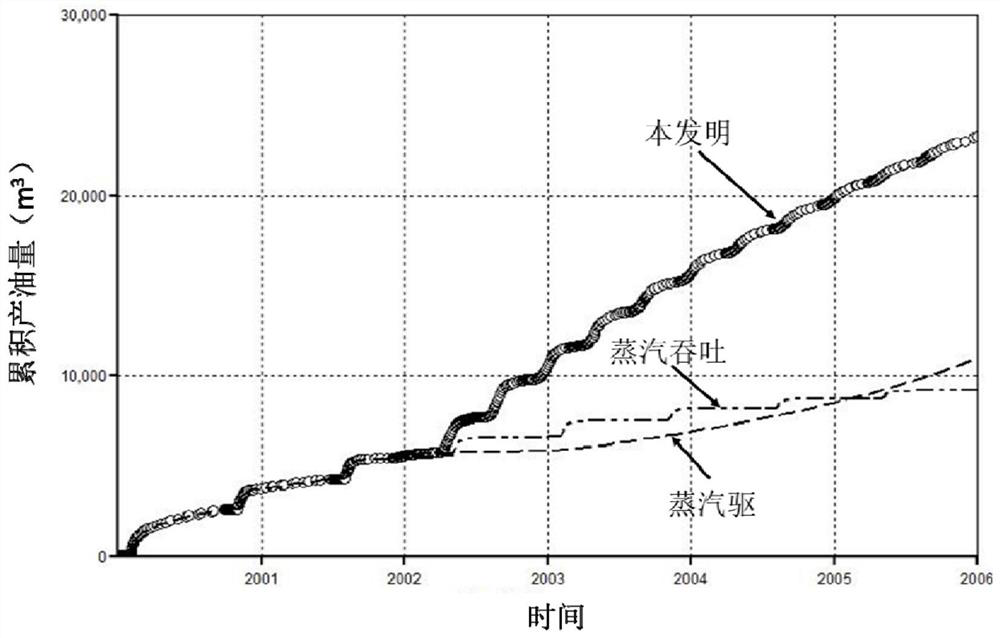

application example 1

[0054] In order to facilitate the understanding of the solutions and effects of the embodiments of the present invention, a specific application example is given below. Those skilled in the art will understand that this example is only for the purpose of facilitating the understanding of the present invention, and any specific details thereof are not intended to limit the present invention in any way.

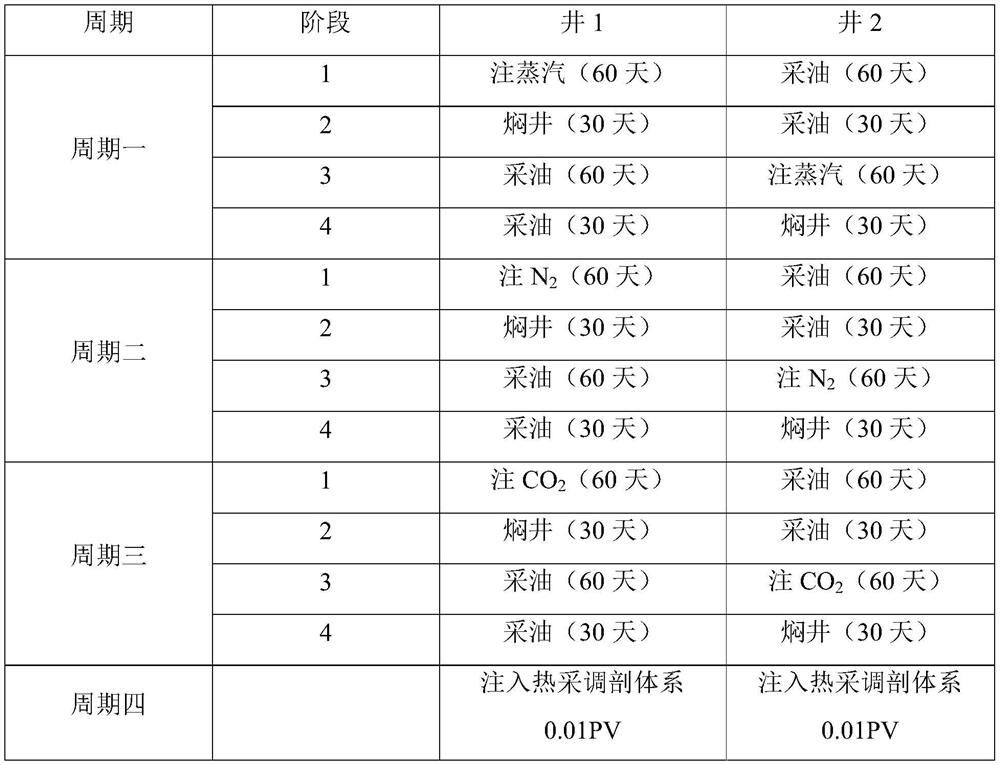

[0055] Taking two horizontal wells as an example, the well spacing is 100 meters, the horizontal section length is 100 meters, the reservoir thickness is 15 meters, the porosity is 35%, and the viscosity of crude oil under formation conditions is 52000mPa.s.

[0056] Step 1: A total of 1 well group, including well 1 and well 2. Among them, the gas injection time is 40-80 days, the brine time is 20-40 days, and the oil production time is 60-120 days.

[0057] Step 2: Inject steam into the well group, specifically: Step 201: Well 1 conducts steam injection operation for 60 days,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com