Automatic control method for thickness of calendered film

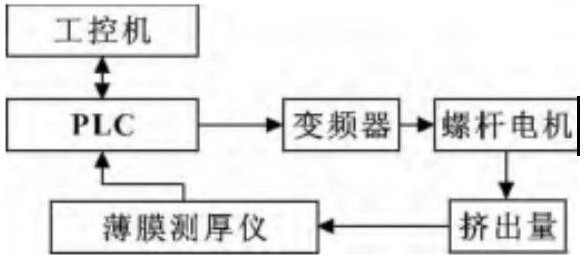

A technology of automatic thickness control and rolling film, which is applied to flat products, household utensils, and other household utensils. It can solve the problem of not considering the precise control of the thickness of the rolling film, and achieve the effect of flexible thickness control and fast and accurate software control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] To produce a film with a calendered thickness of 0.500mm, the steps are as follows:

[0045] 1) Select the appropriate resin according to the needs, mix it with solvent oil, and put it in the oven for curing for a period of time;

[0046] 2) Add the mixture into the barrel of the pre-pressing machine, and pre-press it into a rod-shaped blank;

[0047] 3) Put the billet into the pushing equipment, and extrude a strip with a thickness of 1.5mm through the die by the pushing machine;

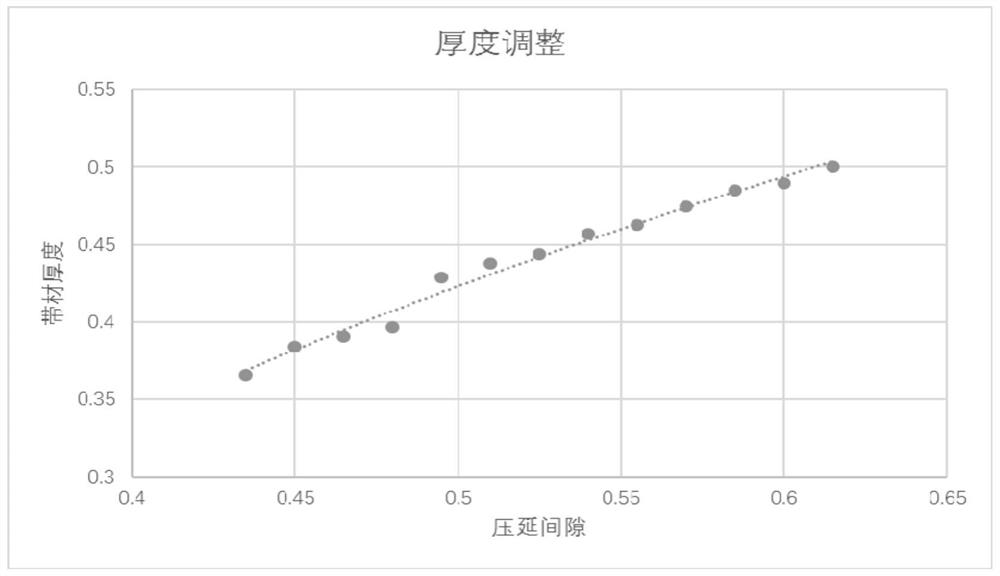

[0048] 4) Put the strip between the calender rollers, set the gap between the calender rollers to 0.620 mm according to production experience, and start the calender. The thickness of the film measured by the thickness gauge at the exit is 0.550mm, which is different from the target thickness of 0.500mm, and the difference is 0.050mm. The software automatically sets the adjustment option of the calender adjustment system to "gap adjustment". Then the software is based on the following form...

Embodiment 2

[0056]To produce a film with a calendered thickness of 0.475mm, the steps are as follows:

[0057] 1) Select the appropriate resin according to the needs, mix it with solvent oil, and put it in the oven for curing for a period of time;

[0058] 2) Add the mixture into the barrel of the pre-pressing machine, and pre-press it into a rod-shaped blank;

[0059] 3) Put the billet into the pushing equipment, and extrude a strip with a thickness of 1.5mm through the die by the pushing machine;

[0060] 4) Insert the strip between the calendering rollers, set the gap between the calendering rollers to 0.570mm according to production experience, then manually set an inlet strip tension of 62mmkg, and start the calendering machine. The thickness of the film measured by the thickness gauge at the exit is 0.485mm, which is different from the target thickness of 0.475mm, and the difference is 0.010mm. The software automatically sets the adjustment option of the calender adjustment system ...

Embodiment 3

[0068] To produce a film with a calendered thickness of 0.430mm, the steps are as follows:

[0069] 1) Select the appropriate resin according to the needs, mix it with solvent oil, and put it in the oven for curing for a period of time;

[0070] 2) Add the mixture into the barrel of the pre-pressing machine, and pre-press it into a rod-shaped blank;

[0071] 3) Put the billet into the pushing equipment, and extrude a strip with a thickness of 1.5mm through the die by the pushing machine;

[0072] 4) Put the strip between the calender rollers, set the gap between the calender rollers to 0.495 mm according to production experience, then manually set a line speed of 4.1 m / min, and start the calender. The thickness of the film measured by the thickness gauge at the exit is 0.435mm, which is different from the target thickness of 0.430mm, and the difference is 0.005mm. The software automatically sets the adjustment option of the calender adjustment system to "speed adjustment". T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com