Plate core embedded type stainless steel combined filter plate and corresponding compartment type filter mechanism

A stainless steel, mosaic technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of easy blockage of the diversion net groove, non-remanufacturing, partial replacement of the plate core, etc., to achieve fast liquid discharge, The effect of saving precious resources and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

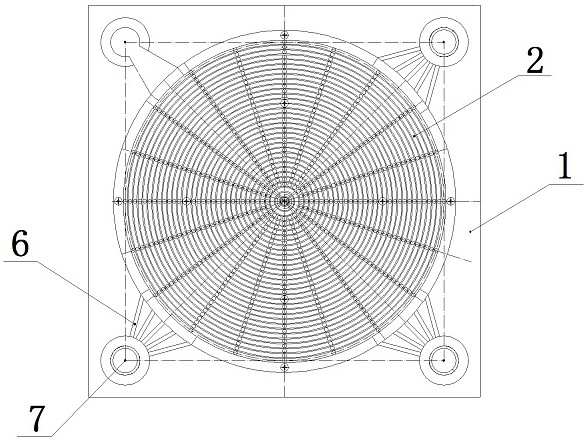

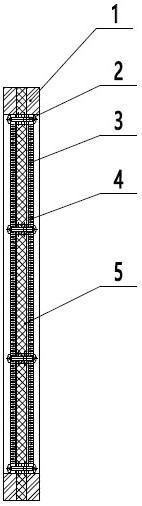

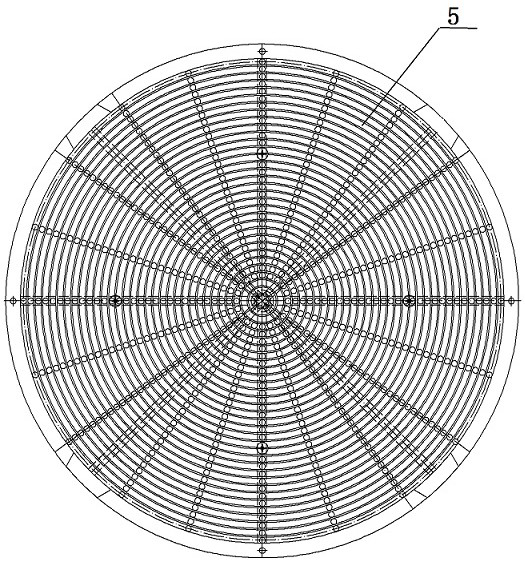

[0021] A plate core embedded stainless steel combined filter plate (hereinafter referred to as: combined filter plate), the main point of the innovative overall implementation plan is to improve the existing stainless steel plate Plate frame split, plate core inlaid combined filter plate (detachable filter plate), including square plate frame 1, detachable filter plate 2, filter plate support 3, fixing screws 4; filter plate support 3 is embedded in the square plate frame 1 chamber (cavity part), the detachable filter disc 2 is installed on the filter disc bracket 3, that is, the filter disc 2 is elevated by the bracket 3 to form a cavity overhead layer, so that the diversion network groove is no longer blocked, and the filtrate is in the filter The bottom of the plate 2 (chamber overhead layer) is unobstructed, ensuring the filtration efficiency and effect will not be affected by clogging; when the filter plate 2 is corroded and damaged, it can be disassembled and replaced to ...

Embodiment 2

[0028]A box-type filter mechanism, using the core-embedded stainless steel composite filter plate provided by the present invention, mainly consists of a front and rear anti-corrosion filter plate, a combined filter plate (this invention), filter cloth, a filter plate support handle, and seals at the end of each fluid inlet and outlet hole It is composed of components such as rings, various fluid inlet and outlet external pipes, etc.; it has the characteristics of high temperature resistance, high pressure resistance, overhead cavity and blockage, and plate core can be replaced. The technical parts shared by the present invention and the prior art are according to the current standards of my country's machinery industry "Van-Type Filter Press and Plate-Frame Filter Press Part 1: Types and Basic Parameters" "Part 2: Technical Conditions" "Part 3" : Manufactured by Filter Plate "JB / T4333-2013.

[0029] The assembly and installation process of the filter mechanism: for the conveni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com