Activated carbon pickling bath fast in response, quick in liquid delivery and low in activated carbon loss

A technology of activated carbon and pickling tank, which is applied in the direction of using liquid cleaning method, filtration separation, fixed filter element filter, etc. The effect of rapid liquid, less loss of activated carbon, and faster reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

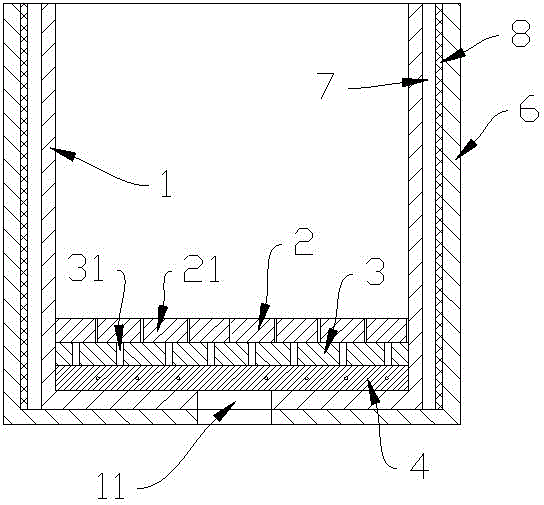

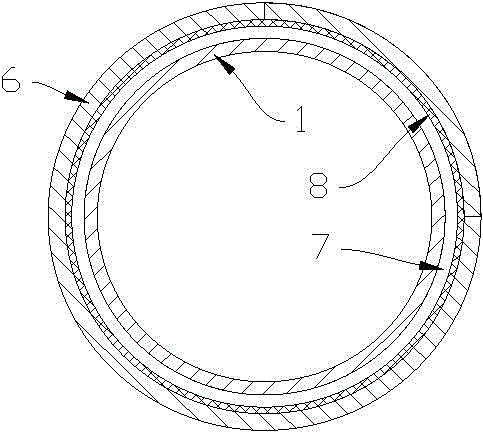

[0016] see figure 1 , 2 The activated carbon pickling tank shown includes a cylinder 1 made of pv plastic with a liquid outlet 11 at the bottom, and a filter layer 2, a filter plate 3, and a separator 4 (including steam Heating tube 5). An annular wall 6 made of refractory bricks and acid-resistant cement surrounding the cylinder is arranged on the outside of the cylinder; there is a gap 7 between the inner wall of the annular wall and the outer wall of the cylinder. A thermal insulation layer 8 is arranged on the inner wall of the annular wall.

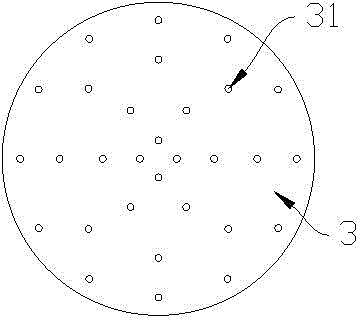

[0017] see image 3 The filter layer 2 shown is formed by laying a plurality of standard refractory bricks 21 naturally, and there are gaps between the refractory bricks. The lower part of the filter layer 2 is a filter plate 3 .

[0018] see Figure 4 The shown filter plate 3 has filter holes 31 on it.

[0019] see figure 1 , 2 , 5-7, the separator 4 is located below the filter plate and directly contacts the inner bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com