New Tail Valves for Pipe-in-Pipe Pipelines

A tail valve, a new type of technology, used in valve devices, control valves, safety valves, etc., can solve the problems of development obstacles, difficult design, and high construction costs, and achieve the effect of rapid liquid discharge and protection of external equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

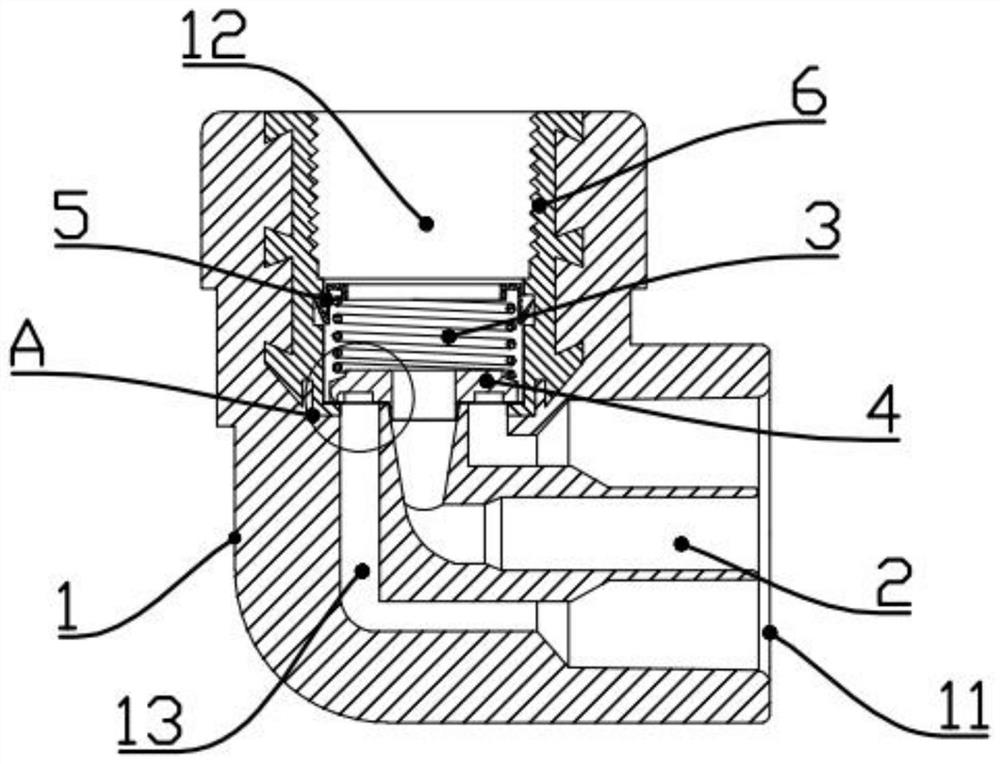

[0049] like Figure 1-4 As shown, a novel tail valve for a pipe-in-pipe pipeline includes a hollow tail valve body 1, and the tail valve body 1 is provided with a tail valve liquid inlet 11 for connecting a pipe-in-pipe and a In connection with the tail valve outlet 12 of the external equipment, the tail valve body 1 is coaxially provided with a corresponding tail valve inner pipe 2, and the tail valve inner pipe 2 is fixed on the tail valve through at least one tail valve connecting rib. Inside the tail valve body 1.

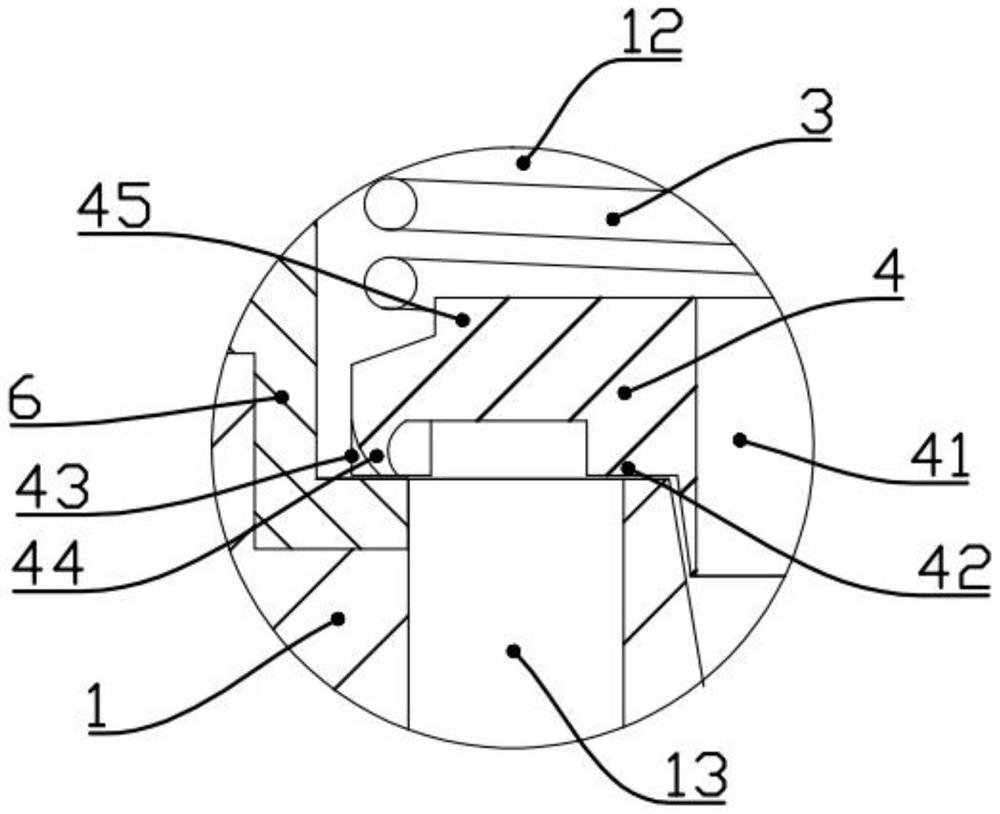

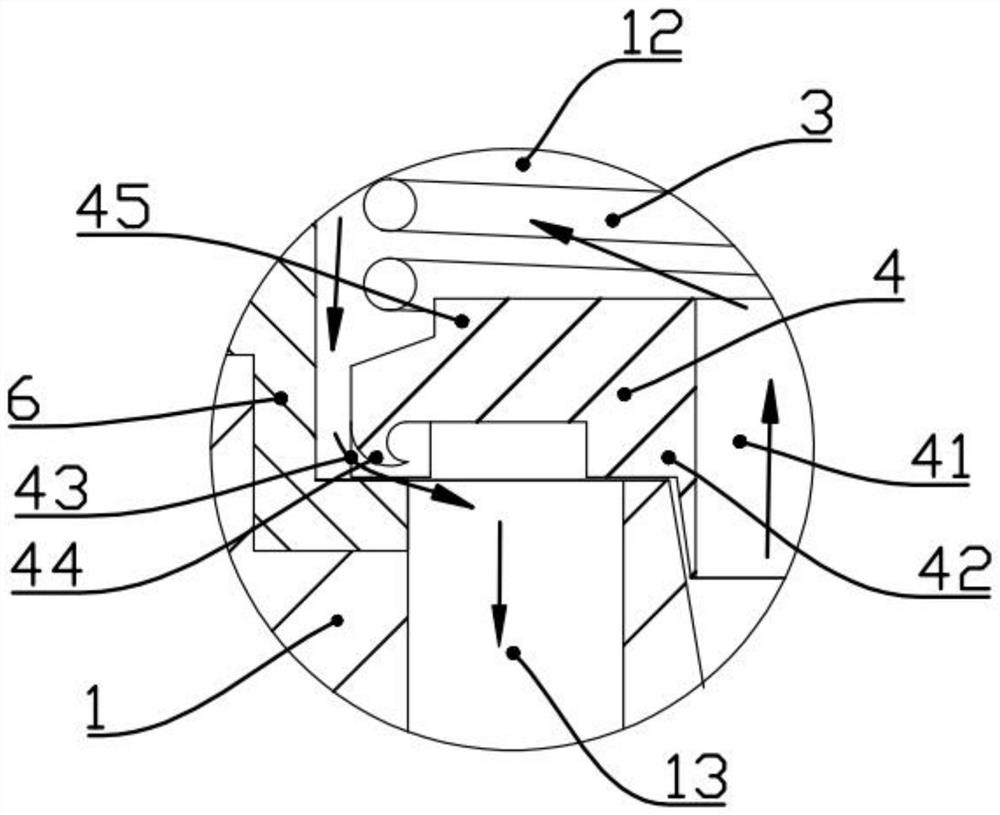

[0050] The liquid outlet end 12 of the tail valve is provided with an elastic member 3 and an elastic valve plate 4, the elastic member 3 is preferably a spring, and the middle part of the elastic valve plate 4 is provided with a liquid outlet hole 41 communicating with the inner pipe 2 of the tail valve, and the The elastic valve plate 4 is moved and sealed at the end of the return cavity 13 of the outer tube through the elastic member 3 .

[0051] Preferabl...

Embodiment 2

[0060] like Figure 5 , 6 As shown, the present embodiment is basically similar to the first embodiment, the difference is that when the outlet valve outlet 12 of the tail valve is under high pressure, the inner annular sealing part 42 is deformed and leads to the return cavity 13 of the outer tube to realize pressure relief.

[0061] Alternatively, the inner annular sealing portion 42 is provided with several pressure relief ribs A44 in the circumferential direction, and when the outlet valve outlet 12 of the tail valve is under high pressure, the pressure relief ribs A44 bend and lead to the return cavity 13 of the outer pipe.

Embodiment 3

[0063] like Figure 7 , 8 As shown, this embodiment is basically similar to Embodiment 1, and the difference is that the elastic valve plate 4 is provided with an air bag 46 inside. Through the outer tube return chamber 13. Its specific structure is that the inner side of the elastic valve plate 4 is arranged in the installation groove on the outer wall of the inner tube of the tail valve, and there is a gap between the outer side and the inner wall of the tail valve valve. The outer side is extruded and deformed and leads to the return cavity 13 of the outer tube, so as to realize pressure relief.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com