Fastening-type modular rubber non-slip mat

A modular, non-slip mat technology, applied to carpets, etc., can solve problems such as high limitations, general practicability, and easy loose anti-slip mat structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

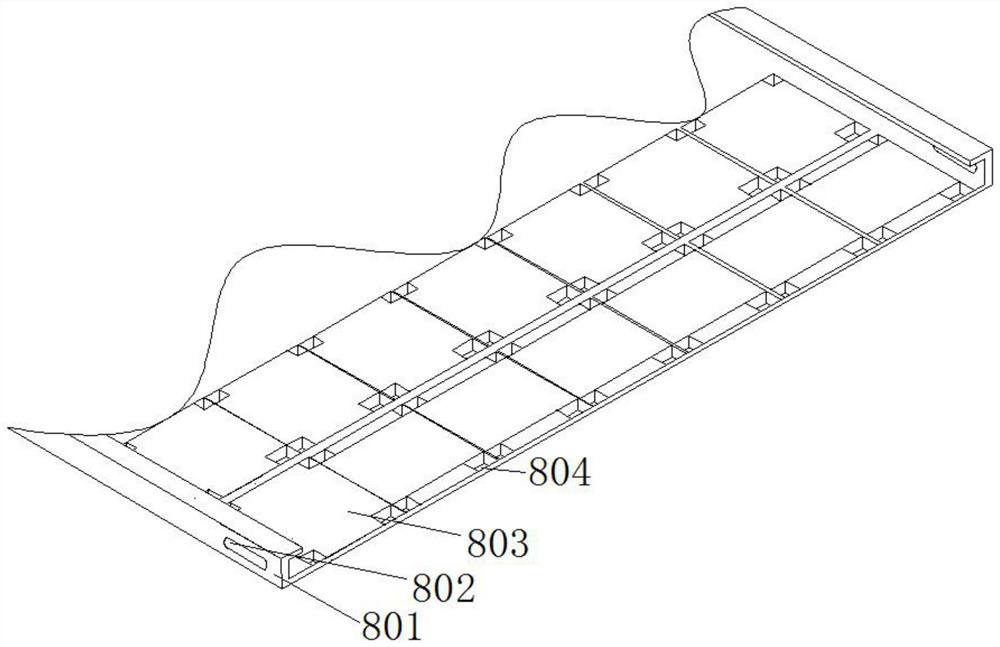

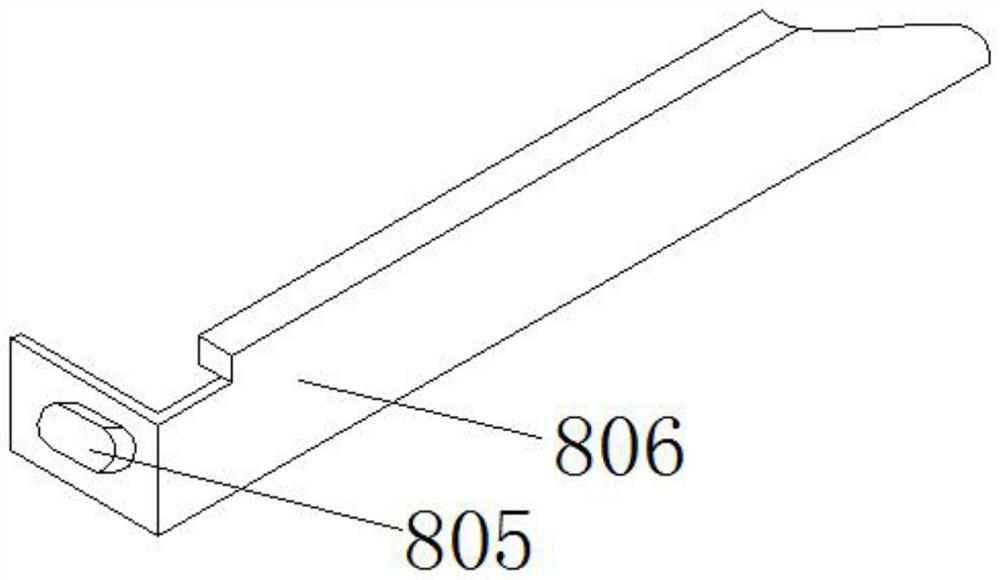

[0046]A fastened modular rubber non-slip mat with air-permeable bottom, comprising a modular anti-slip mat frame 1 and a modular anti-slip mat frame 8, the modular anti-slip mat frame 8 includes a main frame 801, a waist hole 802, and a cross plate 803, a square hole 804, a spring button 805 and a sub-frame 806; the bottom of the main frame 801 is provided with a plurality of square holes 804, and the plurality of square holes 804 are arranged in a matrix, and the side walls of a plurality of adjacent square holes 804 are closely attached to each other. The inside of the square hole 804 is provided with a cross plate 803, the end of the branch of the cross plate 803 is fixedly connected to the middle end of the inner wall of the square hole 804, and the front and rear ends of the side wall of the main frame 801 are provided with a waist-shaped hole 802. The waist-shaped hole 802 has four groups evenly distributed on the left and right ends of the main frame 801; the left and ri...

Embodiment 2

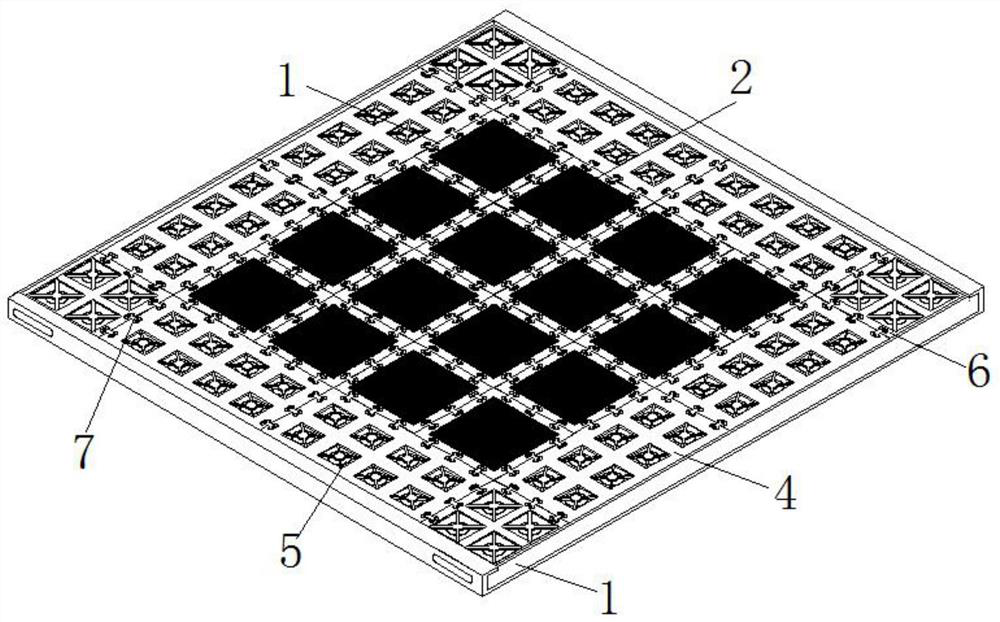

[0048] As an option, see figure 1 , 4 , 5 and 6, fastening type modular rubber anti-slip mat, the interior of the modular anti-slip mat frame 1 is provided with an anti-slip grid 2, and the side wall of the anti-slip grid 2 is fixedly connected to the inner wall of the modular anti-slip mat frame 1 The side wall of the modular anti-slip mat frame 1 is provided with a plurality of connection card slots 3, and the plurality of connection cards 3 are evenly arranged and distributed, and the plurality of modular anti-slip mat frames 1 are arranged in a matrix, and a plurality of adjacent modular anti-slip mats The side walls of the frame 1 are closely fitted. The side walls of the frame 1 of a plurality of edge position modular anti-slip mats are fitted with the side walls of a plurality of first modular side barrier mechanisms 4; the frame first side barrier 401 and the first inner hole 402, the first connecting column 403 and the first connecting strut 404; the inside of the f...

Embodiment 3

[0051] As an option, see figure 1 , 4 , 7 and 9, fastening type modularized rubber anti-slip mats, the frame 1 of the modularized anti-slip mats at the four corners is all fitted with the second modularized side block mechanism 6, and multiple second modularized side block mechanisms 6 are connected with the first module The side block mechanism 4 fits together; the second modular side block mechanism 6 includes a second side block 601, a second inner hole 602, a second connecting column 603 and a second connecting post 604; the inside of the second side block 601 is evenly opened There are a plurality of second inner holes 602, and the plurality of second inner holes 602 are distributed in a matrix. The second connecting columns 603 are arranged in the plurality of second inner holes 602, and the side walls of the plurality of second connecting columns 603 are respectively connected to the plurality of One end of a second connecting strut 604 is fixedly connected, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com