Communication wire suitable for vacuum environment and production process

A vacuum environment and communication line technology, applied in the direction of power cables, communication cables, and conductive materials including electrical communication lines, can solve the problems of impossible signal transmission and power transmission, large precipitation of short molecular chains, and demand constraints. Achieve the effect of smooth appearance, uniform medium and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

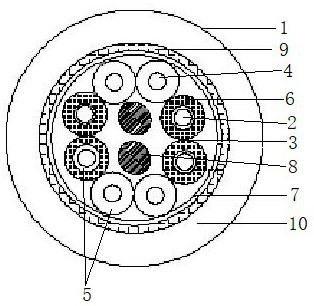

[0031] see figure 1 , a communication wire suitable for a vacuum environment, including a cable body 1, the cable body 1 includes a communication wire 2, a power transmission wire 4, an insulating layer 5, a braided layer 9 and an outer sheath 10, and each of the communication wires 2 wires are twisted into one diagonal wire 3, the communication wire 2 is provided with at least 4 wires, the power transmission wire 4 of the communication wire 2 is arranged every 2 wires and 1 diagonal wire 3, and the power transmission wire 4 There are at least 4 wires, the 2 diagonal wires 3 and the 4 power output wires form a ring structure, the insulating layer 5 is tightly wrapped on the outer surface of each communication wire 2 and power transmission wire 4, and the braided The layer 9 is arranged on the outside of the communication line 2 and the power transmission line 4 , and the outer sheath 10 is tightly covered on the outer surface of the braided layer 9 .

[0032] The four communi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com