Conical pendulum-applied ball screw type memory inerter device

A ball screw type, inertial memory container technology, applied in the field of inertial container devices, can solve the problems of large damping force, large parasitic damping, constant inertia coefficient, etc., achieve small parasitic damping force, enhance adaptability, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

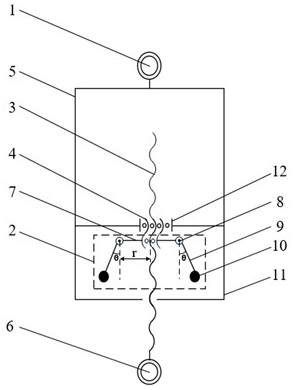

Embodiment 1

[0051] After replacing the flywheel with a conical pendulum in Embodiment 1, the inertia coefficient b in formula (2) can be rewritten as:

[0052]

[0053] Then the kinetic equation of the speed-dependent memory inertia container device described in embodiment 1 and 2 can be expressed as:

[0054] p=b(v)v (6)

[0055] The above formula shows that the inertial characteristics of the device described in Embodiments 1 and 2 are related to the relative speeds of the two ends of the device, so it can be seen that the device described in Embodiments 1 and 2 is a speed-dependent type inerter device.

[0056] Taking the main parameters shown in Table 1 as an example, the mechanical properties of the devices described in Examples 1 and 2 will be described below. The main parameters of the device are shown in Table 1, which is taken as the velocity excitation v=Acos(2πft), where the amplitude A is taken as 0.02m, and the frequency f is taken as 1Hz. The force characteristic curve o...

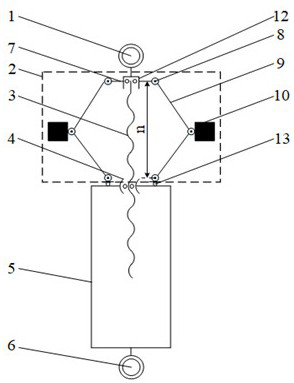

Embodiment 4

[0063] The main difference between embodiment 4 and embodiment 3 is that in embodiment 3, the screw drives the conical pendulum to rotate, while in embodiment 4, the screw nut drives the conical pendulum to rotate.

[0064] Below to image 3 The shown screw rotating type memory container device is taken as an example to illustrate the technical principles and effects of Embodiments 3 and 4.

[0065] It can be seen from formula (2) that the inertial coefficient of the ball screw type inerter is related to the moment of inertia I and the lead screw pitch P. Specifically in Embodiment 3, the moment of inertia I of the conical pendulum 2 is related to the displacement of the lead screw, that is, the displacement of both ends of the inerter container, and the relationship between the moment of inertia I and the displacement x can be described by the following formula.

[0066]

[0067] In the formula, x is the displacement of the lead screw, l is the length of the swing arm, m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com