A metal-sealed automatic exhaust pipe of a circuit breaker hydraulic circuit

A hydraulic circuit, metal sealing technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, servo motor components, etc., can solve the problems of complex structure, high energy consumption, low work efficiency, etc., to achieve exhaust efficiency High, reliable exhaust effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

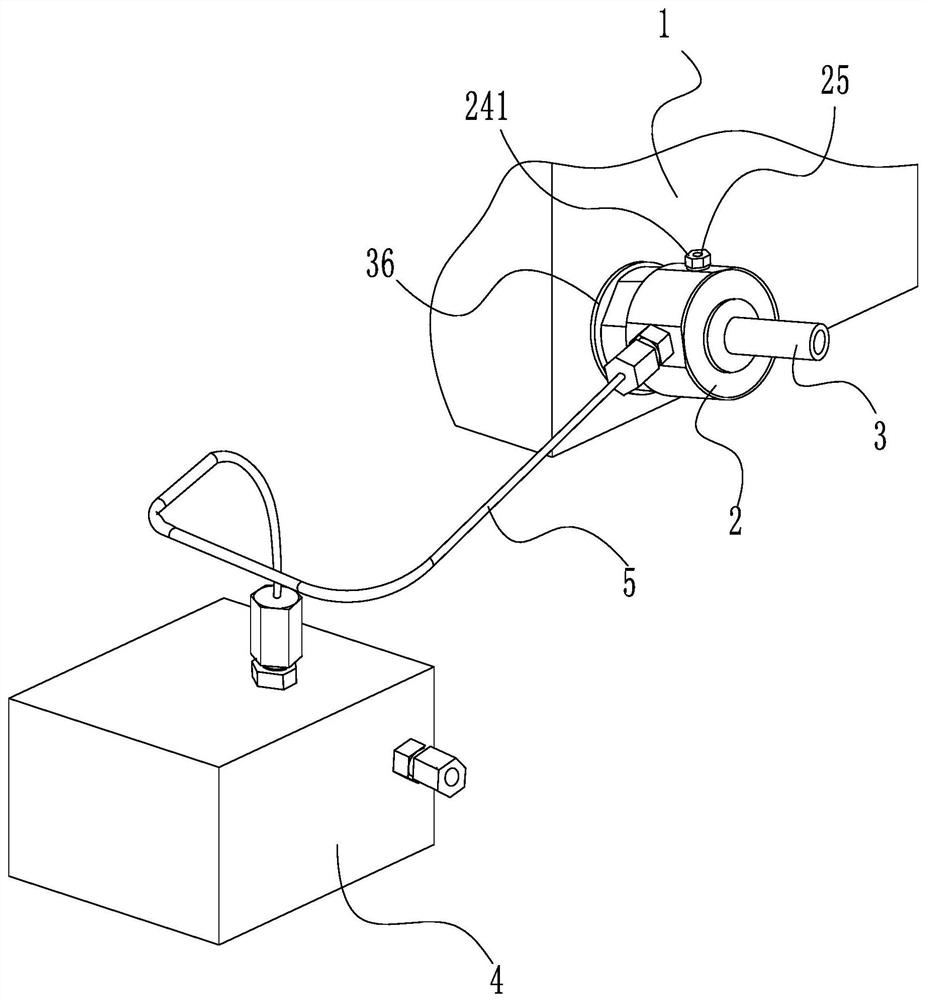

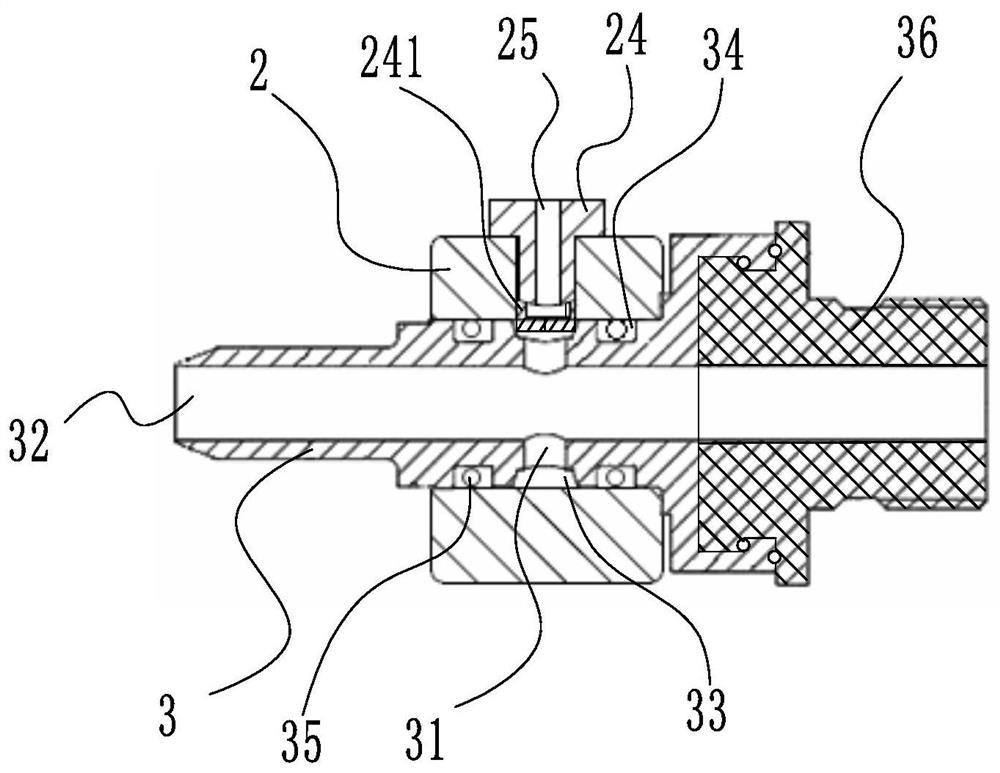

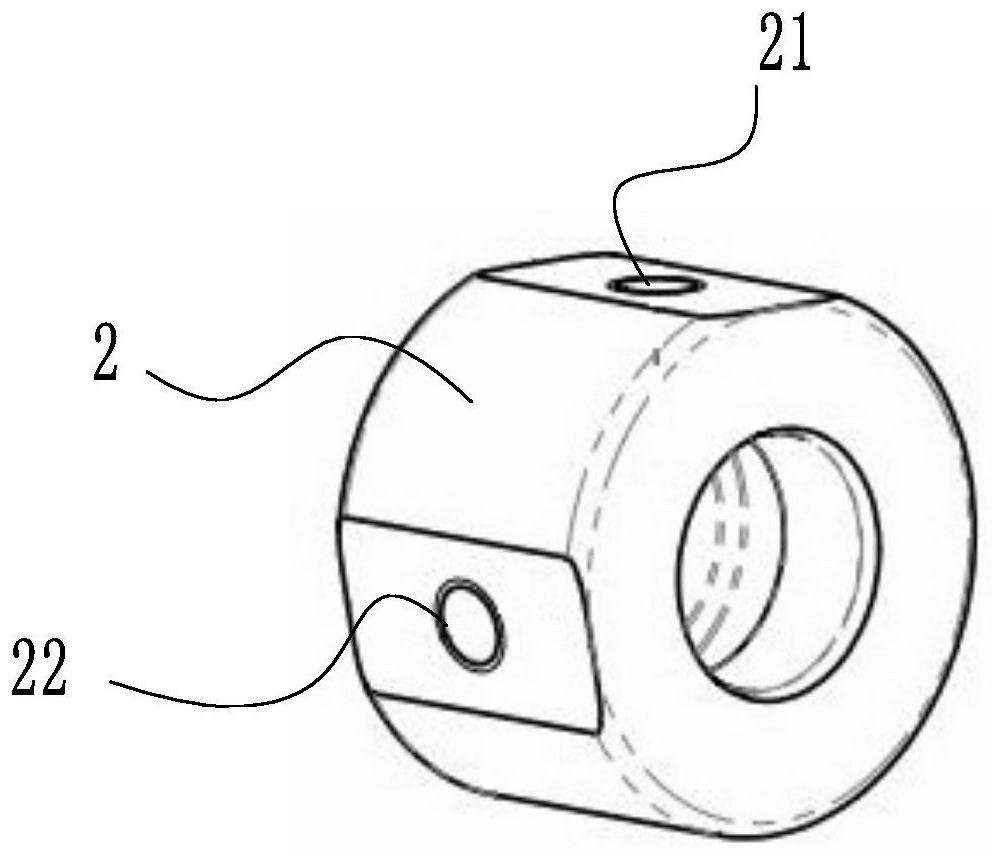

[0029] like Figure 1 to Figure 8 As shown, it is a metal-sealed automatic exhaust pipe of a hydraulic circuit of a circuit breaker, which is characterized in that it is located on the pressure monitoring module 1 of the hydraulic mechanism of the circuit breaker, and includes a valve body located on the pressure monitoring module 1, and the valve body is provided with The exhaust bolt 24 is provided with an exhaust hole 25 in the exhaust bolt 24. The valve body includes a valve block 2 and a sliding body valve core 3 that can rotate relative to the valve block 2. The sliding body valve core 3 is rotatably connected to a rotary seat 36, which rotates The seat 36 is provided with an external thread for threaded connection with the pressure control module. The valve block 2 is provided with a low pressure oil pipe 5, and the valve block 2 is provided with a mounting hole 21 corresponding to the exhaust bolt 24 and an oil inlet hole 22 corresponding to the low pressure oil pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com