Assembly type composite floor

A prefabricated and floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of difficulty in laying the floor at the edge corners, waste of manpower, and floor removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

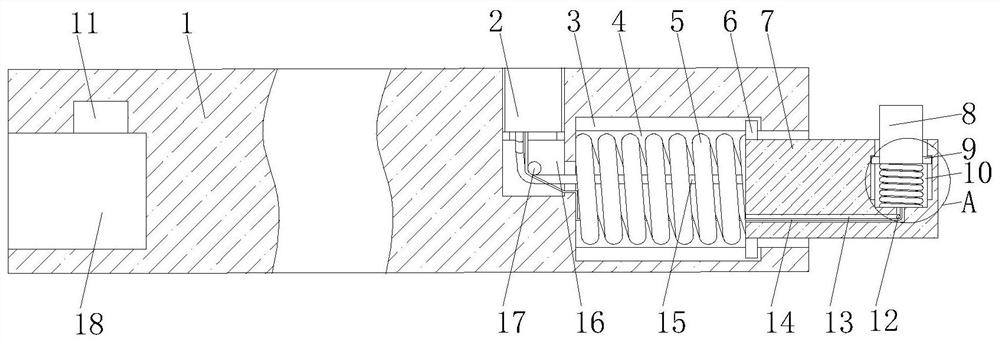

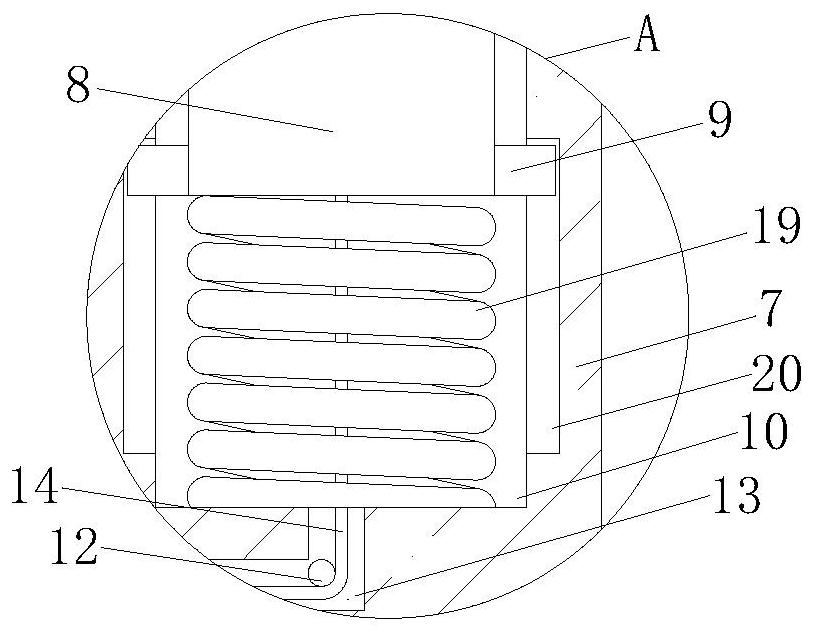

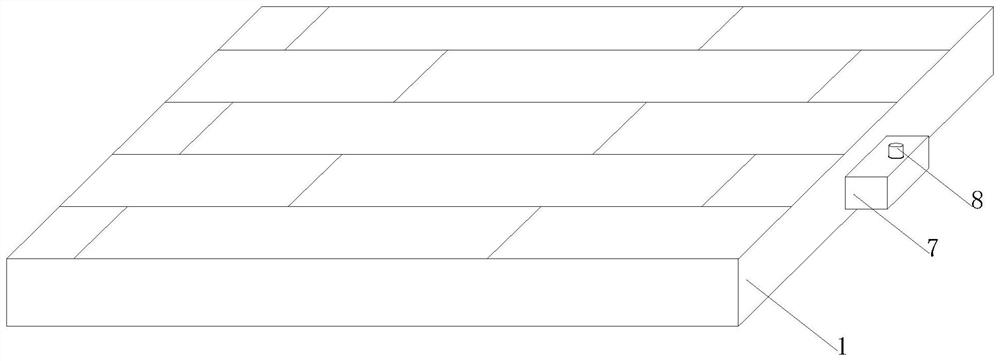

[0022] An assembled combined floor, comprising a floor 1, one side of the floor 1 is provided with a fixing groove 18, the interior of the floor 1 is provided with a limit card groove 11 at the top of the cavity of the fixing groove 18, and the other end of the floor 1 is provided with a second A chute 4, the inside of the floor 1 is provided with first limiting grooves 3 located on the upper and lower sides of the first chute 4, the inside of the floor 1 is provided with a socket hole 16, and the socket hole 16 is connected to the first chute 4 Through, the inner cavity of the first chute 4 is movably socketed with a sleeve column 7, and one end of the sleeve column 7 is fixedly installed with a first support spring 5 located in the inner cavity of the first chute 4, and one end of the first support spring 5 Fixedly connected to one end of the inner cavity of the first chute 4, the surface of one end of the sleeve post 7 is fixedly connected to the first limit post 6, the numb...

Embodiment 2

[0024] The middle part of one end of the socket column 7 is fixedly connected with a second backguy 15, and one end of the second backguy 15 extends to the inner cavity of the socket hole 16 and is fixedly connected with a pull plug 2, and the center of the bottom of the limit block 8 is fixedly connected with a second backguy. A pull wire 14, one end of the first pull wire 14 runs through the inner cavity of the cable arrangement groove 13 and the first chute 4 and extends to the inner cavity of the sleeve hole 16, and one end of the first pull wire 14 is fixedly connected to the bottom of the pull plug 2, The pull plug 2 is movably socketed to the inner cavity of the sleeve hole 16, and the inner cavity of the sleeve hole 16 is fixedly connected with a second rotating column 17, and the second rotating column 17 is located above the second pull wire 15 and the first pull wire 14, The length of the second backguy 15 located in the inner cavity of the sleeve hole 16 is greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com