A prefabricated asphalt-based ballastless track and its construction method

A slab-type ballastless track, prefabricated assembly technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of great influence of weather and climate, large manpower and time consumption, insufficient strength and rigidity, etc., to reduce construction conditions and The influence of progress, the effect of increasing interface friction and uniform bearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

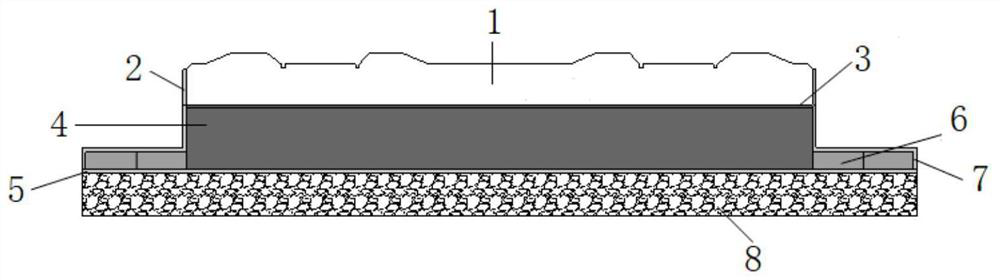

[0038] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as figure 1 As shown, the present invention is a prefabricated asphalt-based ballastless track structure of a preferred embodiment, including a track slab 1 from top to bottom, a non-woven geotextile 3, a dense asphalt concrete layer 4, and a permeable layer 5 , Grain base 8.

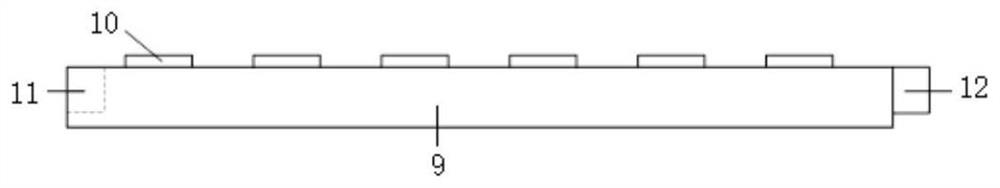

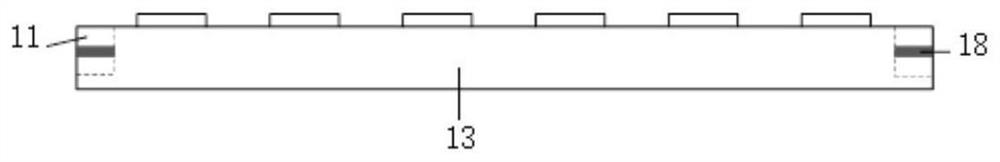

[0039] In this embodiment, the track slab is a C60 concrete slab, which has two forms: unit type and longitudinal connection type.

[0040] In this embodiment, a non-woven geotextile is laid between the track slab 1 and the dense asphalt concrete layer 4 to prevent reflection cracks in the asphalt layer.

[0041] In this embodiment, the asphalt layer is a compact asphalt concrete layer with a layer thickness of 200-350mm, E v2 ≥150N / mm 2 .

[0042]In this embodiment, all types of asphalt concrete can be used as the prefabricated asphalt concrete layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com