Sphere-like superfine barium nitrate, preparation method and application thereof

A technology of barium nitrate and spherical shape, applied in the direction of calcium/strontium/barium nitrate, explosives, etc., to achieve the effect of solving technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a preparation method of spherical ultrafine barium nitrate, comprising the following steps:

[0024] Under the condition of stirring, the saturated aqueous solution of barium nitrate is added dropwise into the anti-solvent for recrystallization to obtain the spherical ultrafine barium nitrate; the temperature of the saturated aqueous solution of barium nitrate is higher than the temperature of the anti-solvent.

[0025] In the present invention, unless otherwise specified, each component in the preparation method is a commercially available product well known to those skilled in the art.

[0026] In the present invention, under the condition of stirring, the saturated aqueous solution of barium nitrate is added dropwise into the anti-solvent, and the recrystallization is carried out to obtain the spherical ultrafine barium nitrate.

[0027] In the present invention, the preparation method of the saturated aqueous solution of barium nitrate is as f...

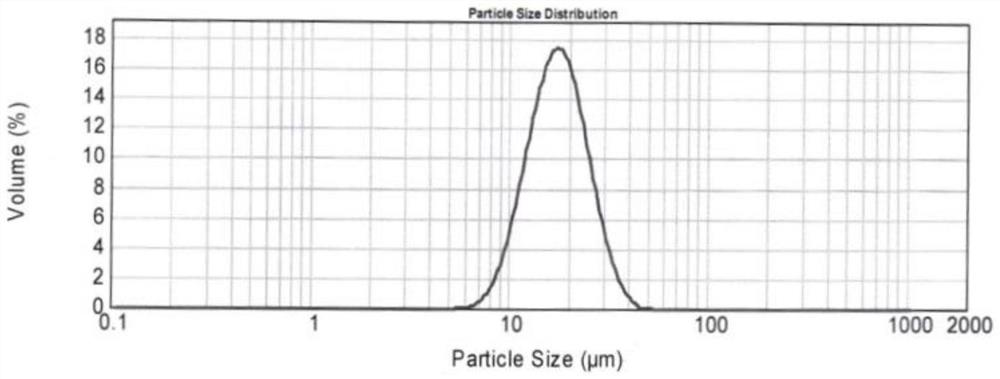

Embodiment 1

[0049] 30g of barium nitrate and 150g of water were mixed, and the temperature was raised to 60°C at a rate of 2.0°C / min at a stirring rate of 280rpm to obtain a saturated aqueous solution of barium nitrate;

[0050] Cool down to 0-10°C with 150g of ethanol at a rate of 5°C / min;

[0051] Under the condition that the ethanol is stirred at a rate of 480rpm, the dropping rate is controlled at 6.0g / min, and the saturated aqueous solution of barium nitrate is added dropwise to the ethanol. Under the condition of ℃, the filter cake obtained by filtering is dried, and then the dried product is passed through a 200-mesh sieve, and the under-sieve is the spherical superfine barium nitrate.

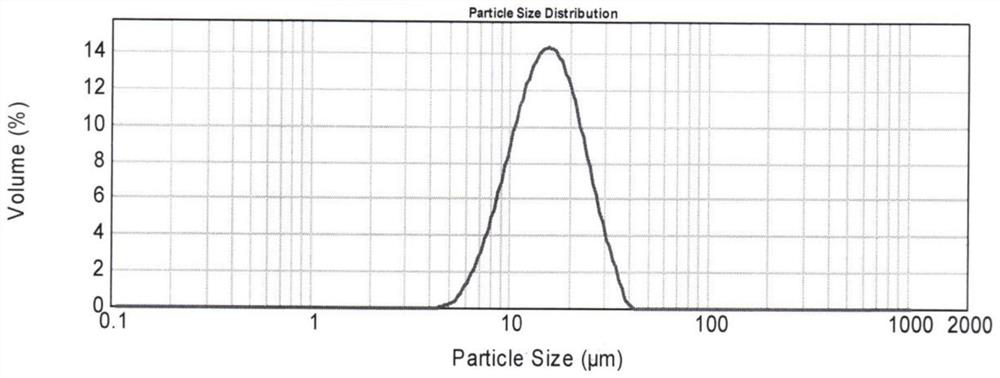

Embodiment 2

[0053] 25.65g of barium nitrate and 150g of water were mixed, and the temperature was raised to 50°C at a rate of 1.5°C / min at a stirring rate of 260rpm to obtain a saturated aqueous solution of barium nitrate;

[0054] Cool down to 0-10°C with 150g of ethanol at a rate of 4°C / min;

[0055] Under the condition that the ethanol is stirred at a rate of 460rpm, the dropping rate is controlled at 5.8g / min, and the saturated aqueous solution of barium nitrate is added dropwise to the ethanol. Under the condition of ℃, the filter cake obtained by filtering is dried, and then the dried product is passed through a 200-mesh sieve, and the under-sieve is the spherical superfine barium nitrate.

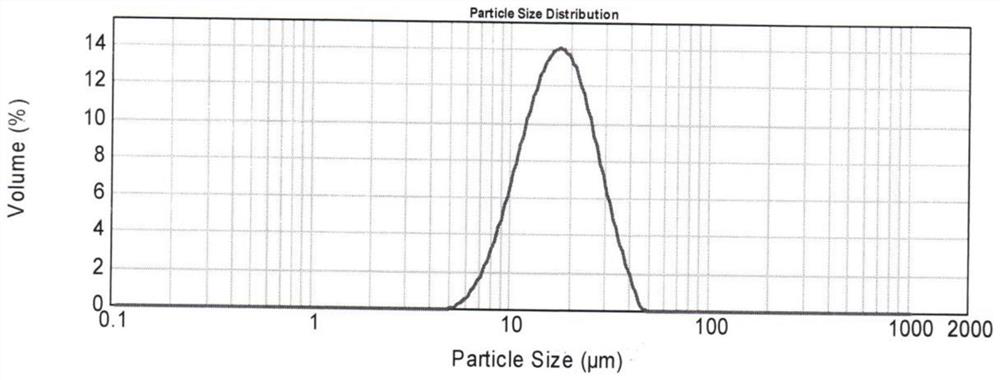

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com