Method for preparing nanometer carbon black powder

A technology of nano-carbon black and carbon black powder, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effect of simple equipment, short process and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

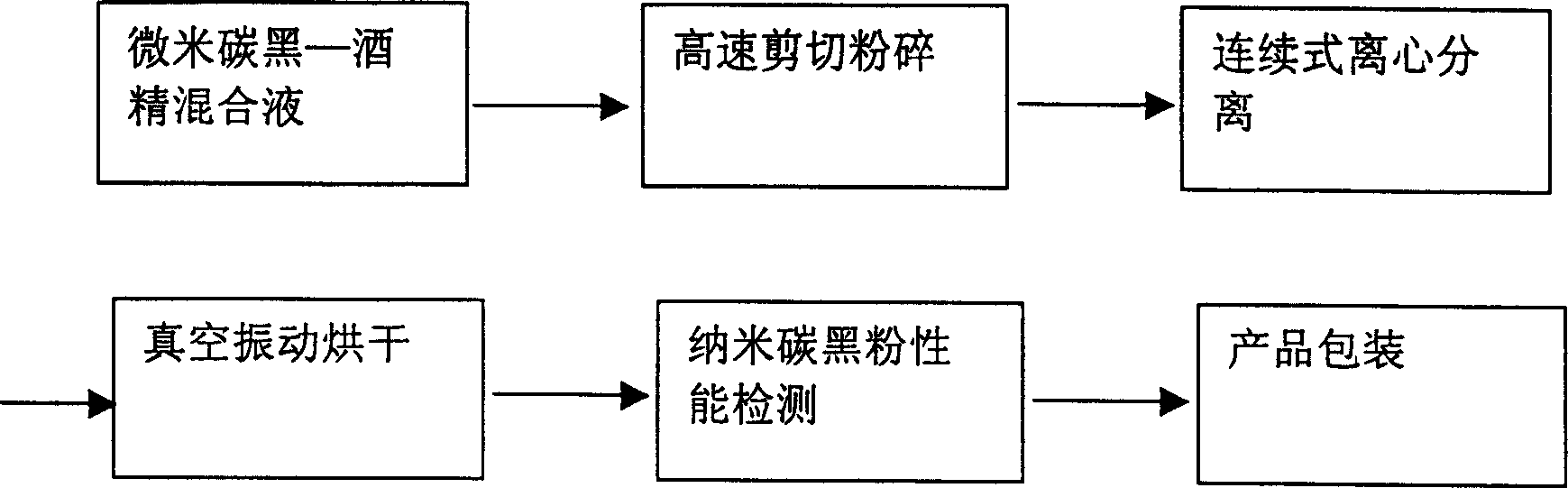

Image

Examples

Embodiment 1

[0025] Embodiment 1: should finish according to following steps when preparing 1kg nanometer carbon black powder.

[0026] 1. Weigh 1.05kg of micron carbon black powder, add 4.2kg of industrial alcohol according to micron carbon black: industrial alcohol = 1: 4 (mass ratio), and use an automatic mechanical mixer in the container to stir for 20 minutes to prepare The micron carbon black-alcohol colloid solution is poured into the solution tank of the high-speed shearing machine pulverizer.

[0027] 2. Start the solution circulation pump of the high-speed shear pulverizer, send the micron carbon black-alcohol mixture into the pulverization cavity of the high-speed shear pulverizer, and start the shear pulverizer at the same time, adjust the speed to reach (10000 rpm) After shearing for 60 minutes, the micron-sized carbon black particles in the mixed solution were all pulverized into nano-sized (median particle diameter≤10nm) carbon black particles, and the obtained nano-carbon b...

Embodiment 2

[0032] Embodiment 2: When preparing 10kg nano-carbon black powder, it should be completed according to the steps in the example.

[0033] 1. Weigh 10.5kg of micron carbon black powder, add 63kg of industrial alcohol according to micron carbon black: industrial alcohol = 1:6 (mass ratio), and use an automatic mechanical mixer in the container. After stirring for 50 minutes, pour the mixed solution into In the solution tank of the high-speed shearing machine pulverizer.

[0034] 2. Start the solution circulation pump of the high-speed shear pulverizer, send the micron carbon black-alcohol mixture into the pulverization chamber of the high-speed shear pulverizer, and start the shear pulverizer at the same time, adjust the speed to reach (20000 rpm) After shearing for 30 minutes, the micron-sized carbon black particles in the mixed solution are all crushed into nano-sized (median particle diameter≤10nm) carbon black particles, and nano-sized carbon black-alcohol colloidal solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com