Tool for machining

A technology for cutting processing and tools, which is applied in the direction of cutting tools, tool holders, and manufacturing tools for lathes. It can solve problems such as tool failure and cutting blades cannot be reliably maintained, and achieve the effect of optimizing elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

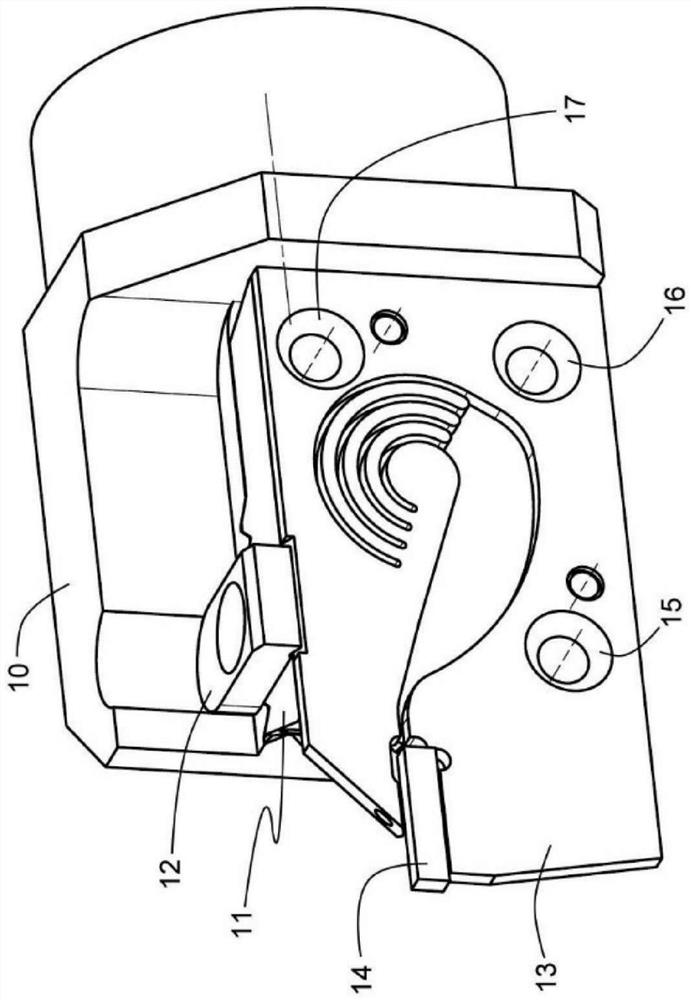

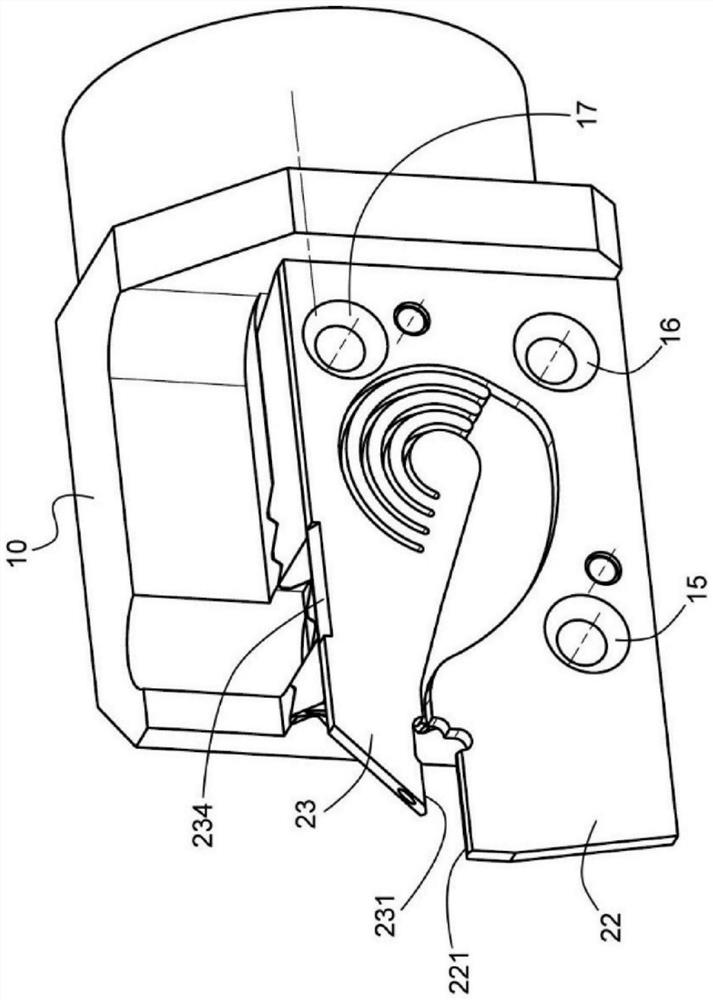

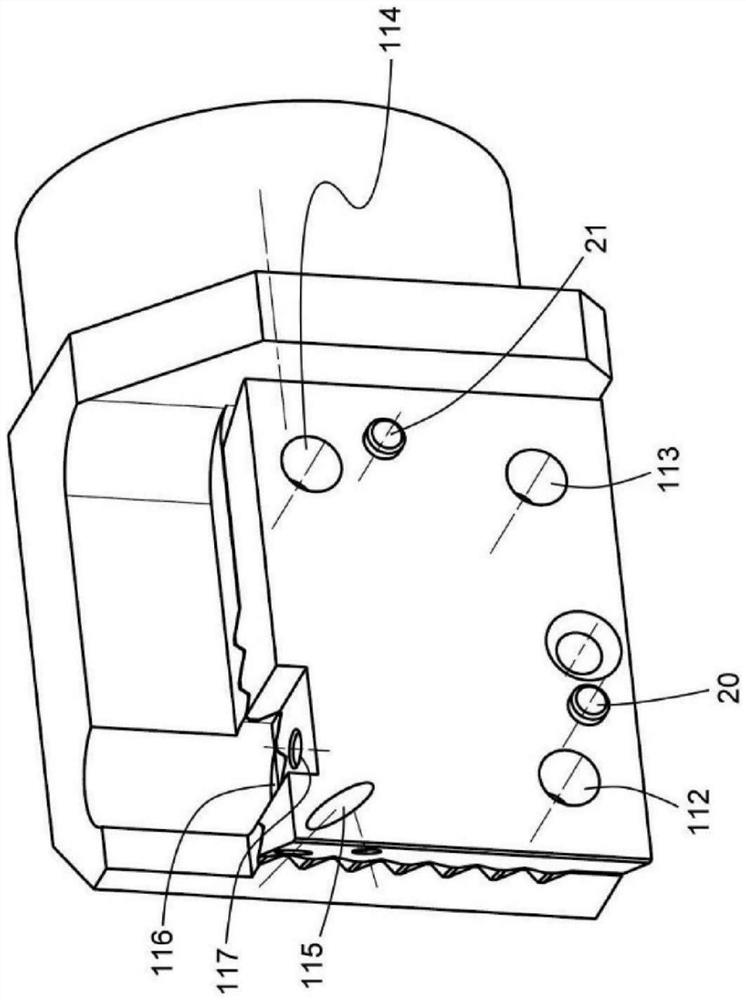

[0027] Basic tool holders are known in principle according to the prior art, and include connections on the power tool, for example HSK hollow tapers, and corresponding coolant feeds. In the present case, the complete tool consists of a basic tool support 10, a carrying box 11, and a clamping support 13, on which clamping jaws 12 are fastened and to which cutting inserts 14 are clamped. clamped into the bracket. The clamping bracket has three bores 15 , 16 , 17 including countersinks, through which a screw can be inserted with a countersink and used for screwing to the carrier box 11 . A slight offset of the holes 15 , 16 , 17 relative to the threaded holes in the carrier box can ensure, as is known in the prior art, that the clamping bracket when actuating the clamping screw is pulled into the desired end position.

[0028] Other holes 18, 19 (see Figure 6 ) for ensuring the first positioning of the clamping bracket by the pins 20 , 21 protruding from the carrier box 11 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com