Automatic straightening and shaping equipment used after welding deformation of box girder piece, and using method of automatic straightening and shaping equipment

A welding deformation and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of troublesome adjustment, low operation efficiency, removal of jacks and upper beams, etc., to achieve the effect of rapid detection and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will be further described in detail below in conjunction with the drawings.

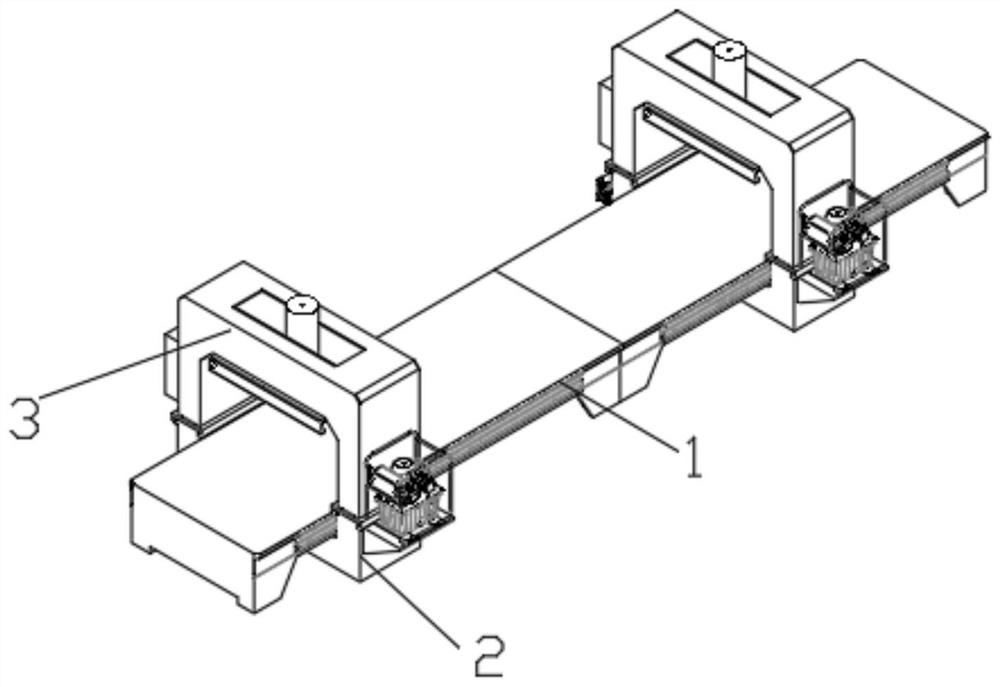

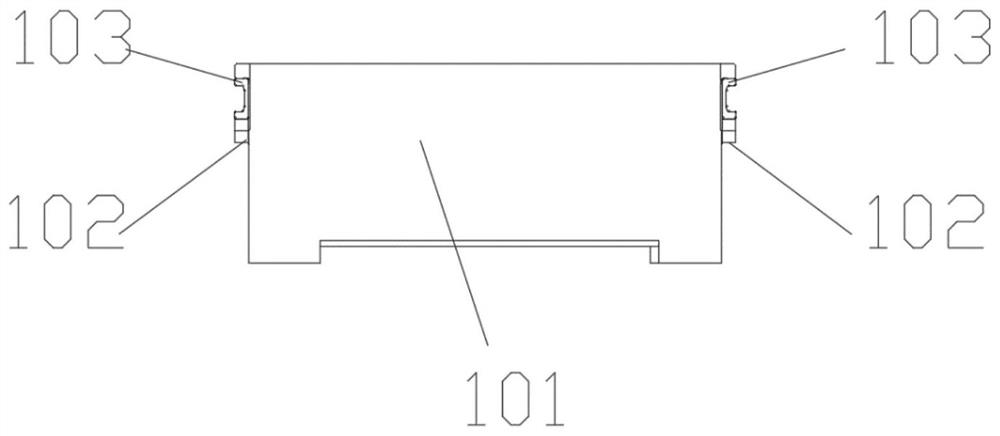

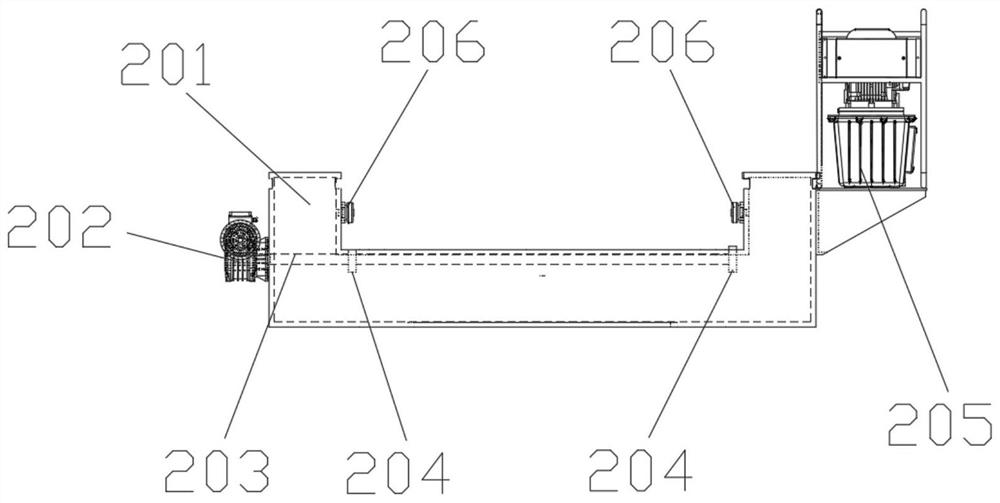

[0022]Attachedfigure 1 To attachFigure 5 , The present invention provides an automatic straightening and shaping equipment for box girder parts after welding deformation, which includes a tooling main platform 1, at least one gantry structure, a support block 401 for supporting a workpiece that needs to be shaped, and a measuring workpiece Whether to adjust the height measuring tool 402 in place, the lower part of the gantry structure can move back and forth on the main tooling platform 1; the upper part of the gantry structure is equipped with a high-pressure jack 304, and the high-pressure jack 304 can be installed in the gantry structure. There are at least two supporting blocks 401, which are detachably connected to the main tooling platform 1; there are at least two height measuring tools 402, which are provided on the outer wall Contour block for measuring scale.

[0023]Prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com