RFID batching goods shelf assisting mechanical arm in loading

A technology of auxiliary machinery and shelves, applied in the field of Internet of Things, can solve problems such as low success rate and complexity, and achieve the effect of improving production efficiency and facilitating grasping and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

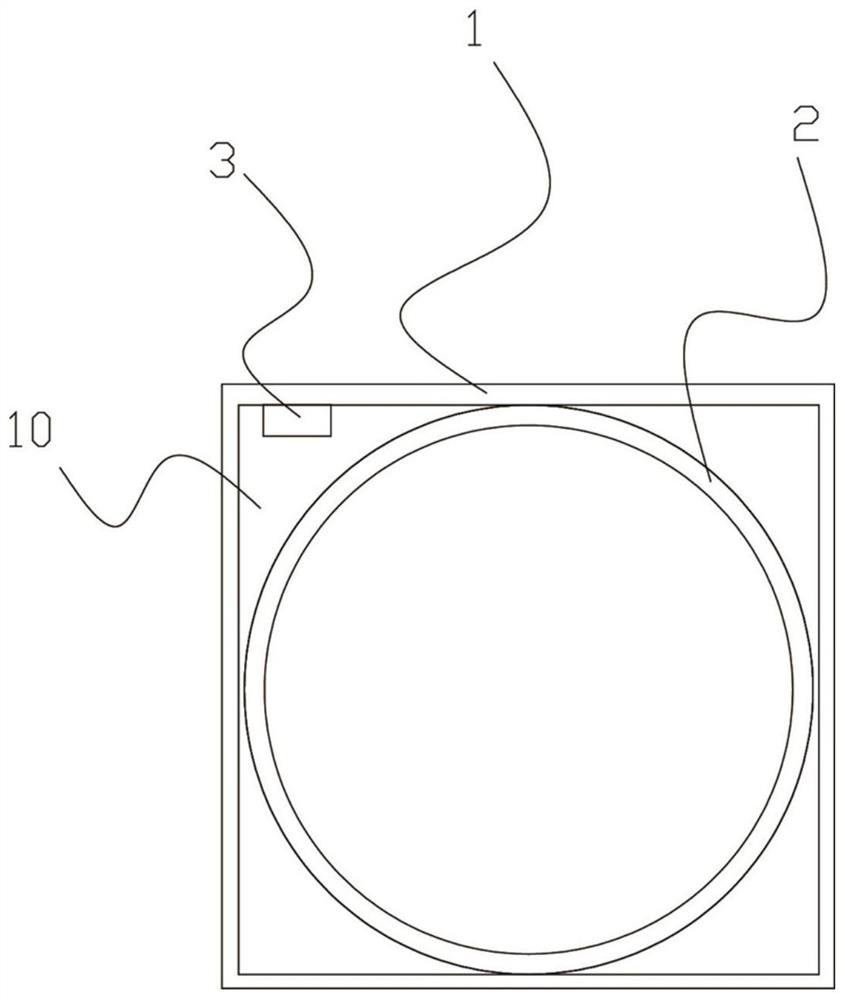

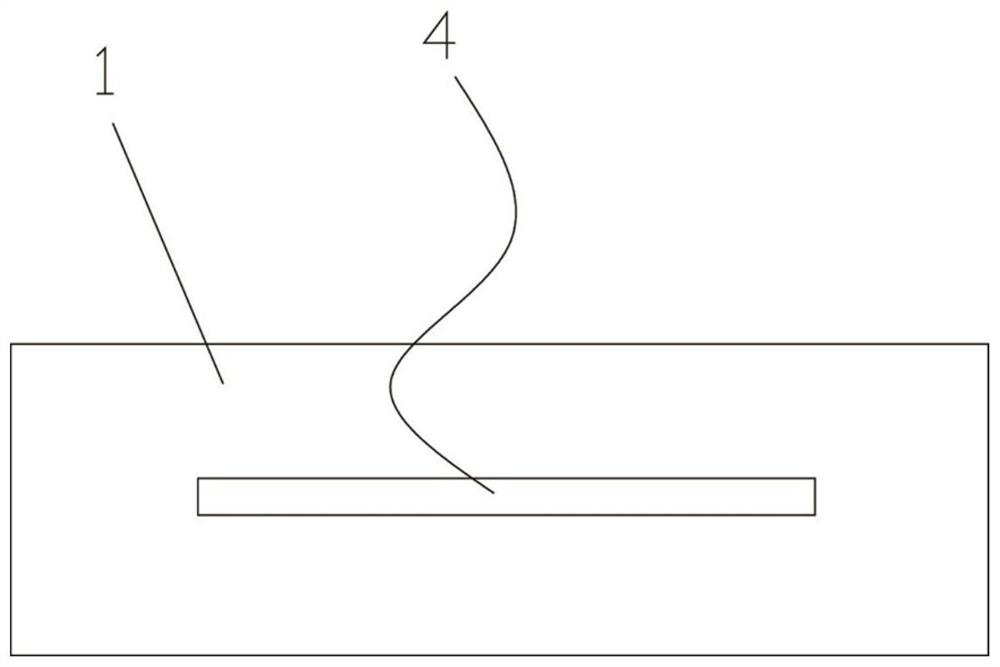

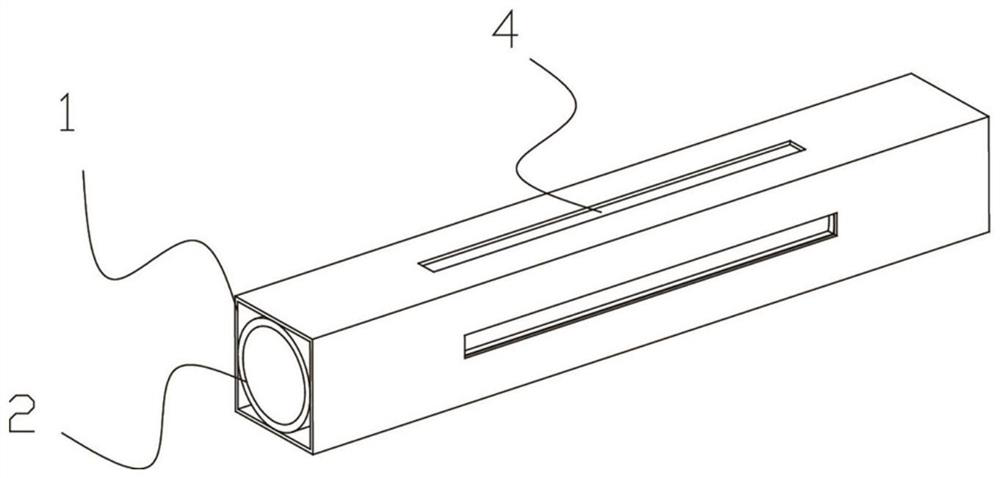

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 to image 3 , an RFID rolled cloth shelf for assisting mechanical arm loading, comprising an outer tube 1 in a straight quadrangular prism and an inner tube 2 in a cylindrical shape, the inner tube is inscribed on the inner wall of the outer tube, and the outer tube A gap 10 is formed between the inner tube and an RFID chip 3 is arranged in the gap 10 , and an opening 4 extending longitudinally along the outer tube is arranged on the outer wall of the outer tube.

[0014] In the above structure, the outer tube wall is a straight quadrangular prism. Compared with the original cylindrical cloth roll, there are grooves of different sizes after stacking. The square prism does not leave gaps, and the stack is stable; the inner tube wall is a cylinder. When used, the rolled cloth placed in the inner tube. First of all, the rolled cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com