A new energy vehicle water-cooled condenser with heat exchange structure

A new energy vehicle and heat exchange structure technology, applied in heat exchange equipment, evaporator/condenser, heat exchanger shell, etc., can solve problems such as inconvenient disassembly and cleaning, and impact on the service life of cooling pipes, so as to increase the cleaning effect , reduce dust, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

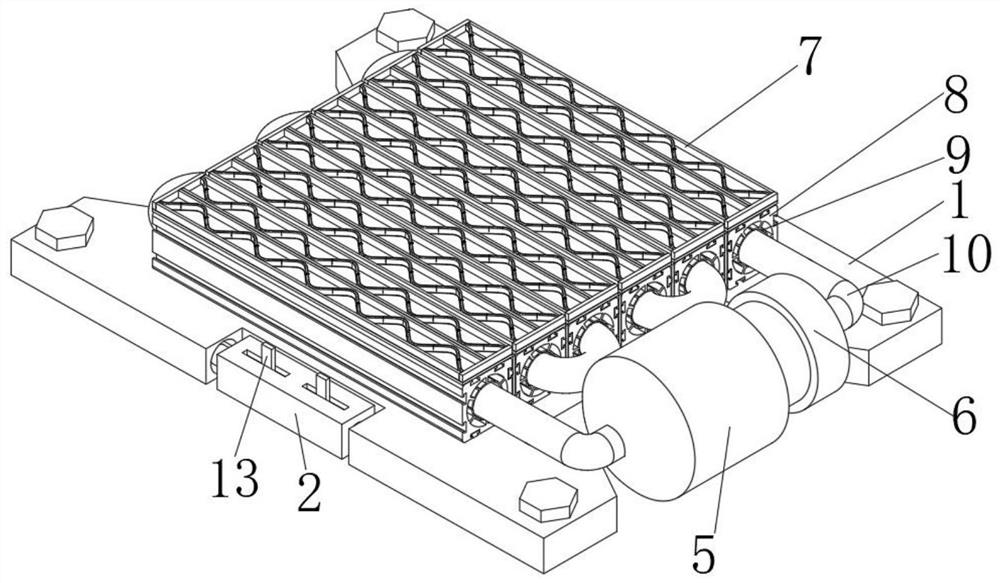

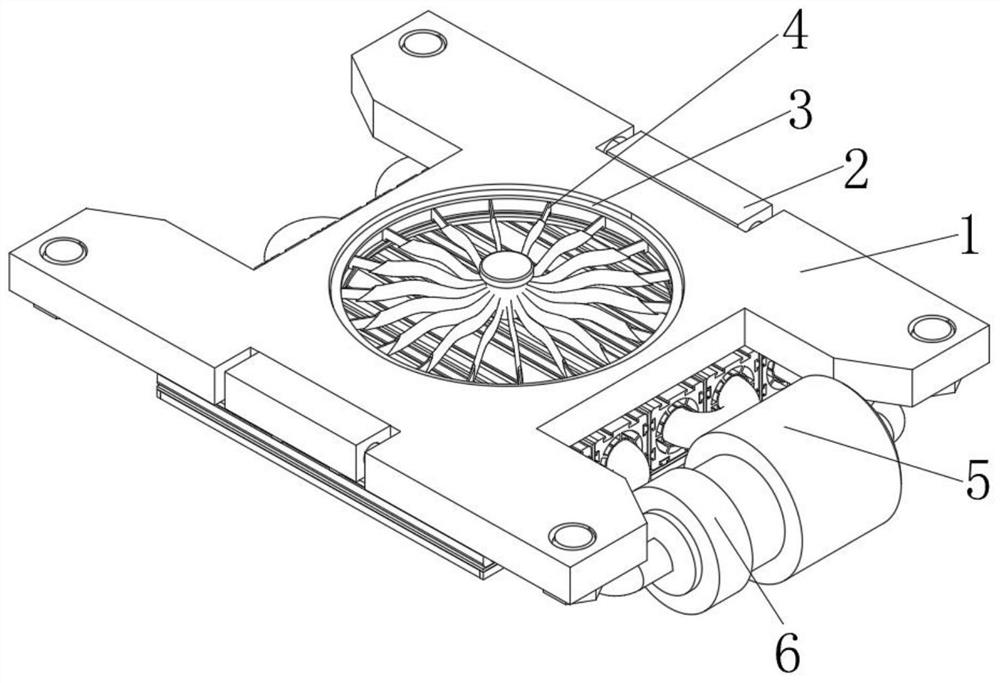

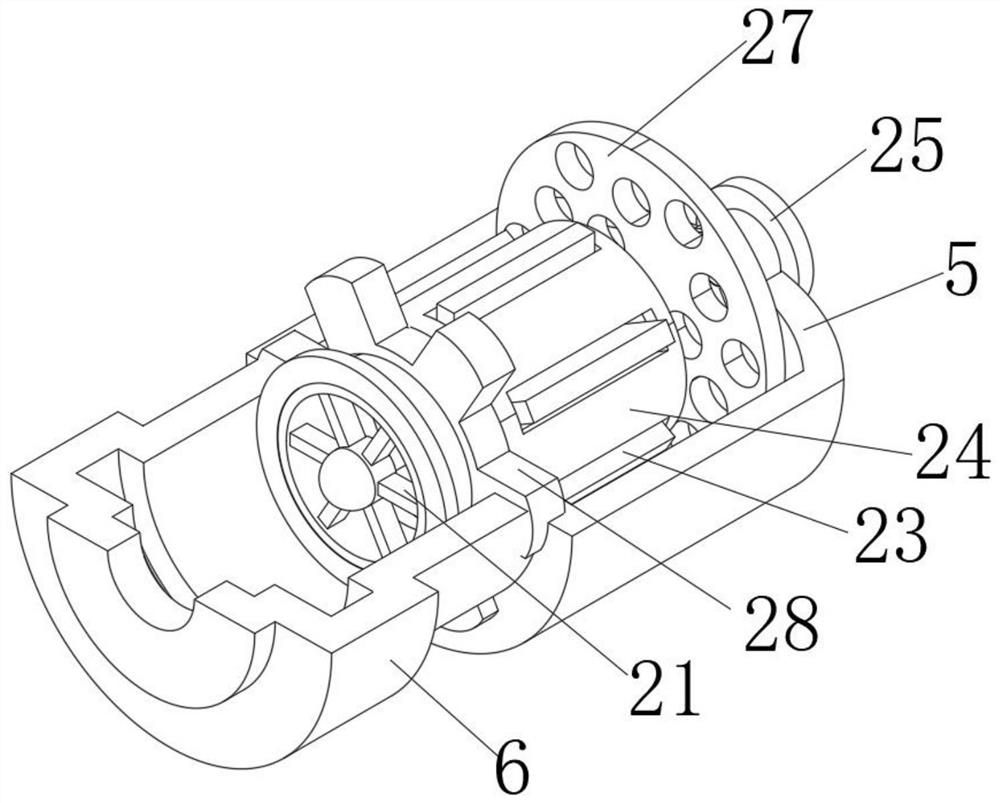

[0031] A water-cooled condenser for a new energy vehicle with a heat exchange structure, comprising a main body of the water-cooled condenser, the main body of the water-cooled condenser includes a fixed substrate 1, one end of the fixed substrate 1 is connected with a metal guide box 8, and the metal guide box 8 The outer surface of the metal guide box 8 is in contact with a heat conduction mechanism, and a cooling water pipe 10 is inserted inside the metal guide box 8, and one end of the cooling water pipe 10 is connected to a purification mechanism, and one end of the fixed substrate 1 is connected to the first connection box 2, and the first connection The inside of the box 2 is connected with a fixing mechanism, and one end of the metal guide box 8 is connected with a first connecting plate 14, and one side of the first connecting plate 14 is connected with an inner connecting bar 15;

[0032] The heat conduction mechanism includes an inner guide piece 9, a metal guide pie...

Embodiment 2

[0042] A water-cooled condenser for a new energy vehicle with a heat exchange structure, comprising a main body of the water-cooled condenser, the main body of the water-cooled condenser includes a fixed substrate 1, one end of the fixed substrate 1 is connected with a metal guide box 8, and the metal guide box 8 The outer surface of the metal guide box 8 is in contact with a heat conduction mechanism, and a cooling water pipe 10 is inserted inside the metal guide box 8, and one end of the cooling water pipe 10 is connected to a purification mechanism, and one end of the fixed substrate 1 is connected to the first connection box 2, and the first connection The inside of the box 2 is connected with a fixing mechanism, and one end of the metal guide box 8 is connected with a first connecting plate 14, and one side of the first connecting plate 14 is connected with an inner connecting bar 15;

[0043] The heat conduction mechanism includes an inner guide piece 9, a metal guide pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com