Shockproof bracket for civil engineering machinery

A mechanical and civil engineering technology, applied in the direction of machine/support, mechanical equipment, supporting machine, etc., can solve the problems of poor ubiquity, inability to cooperate with scaffolding equipment, etc. The effect of position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

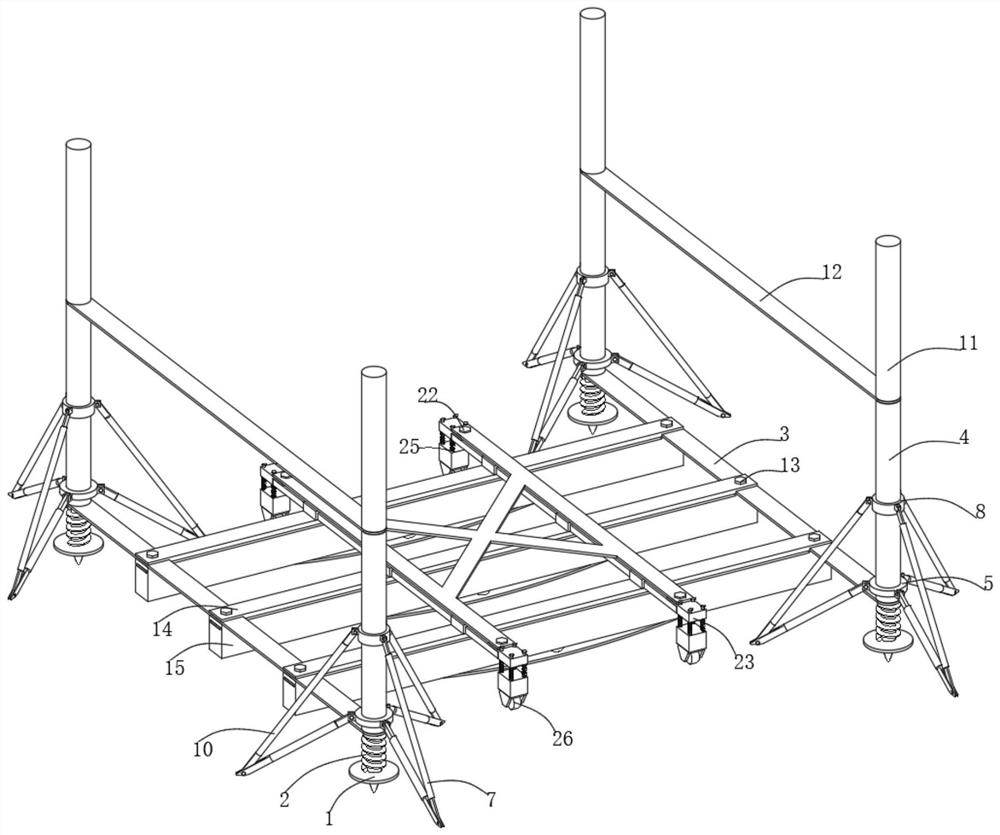

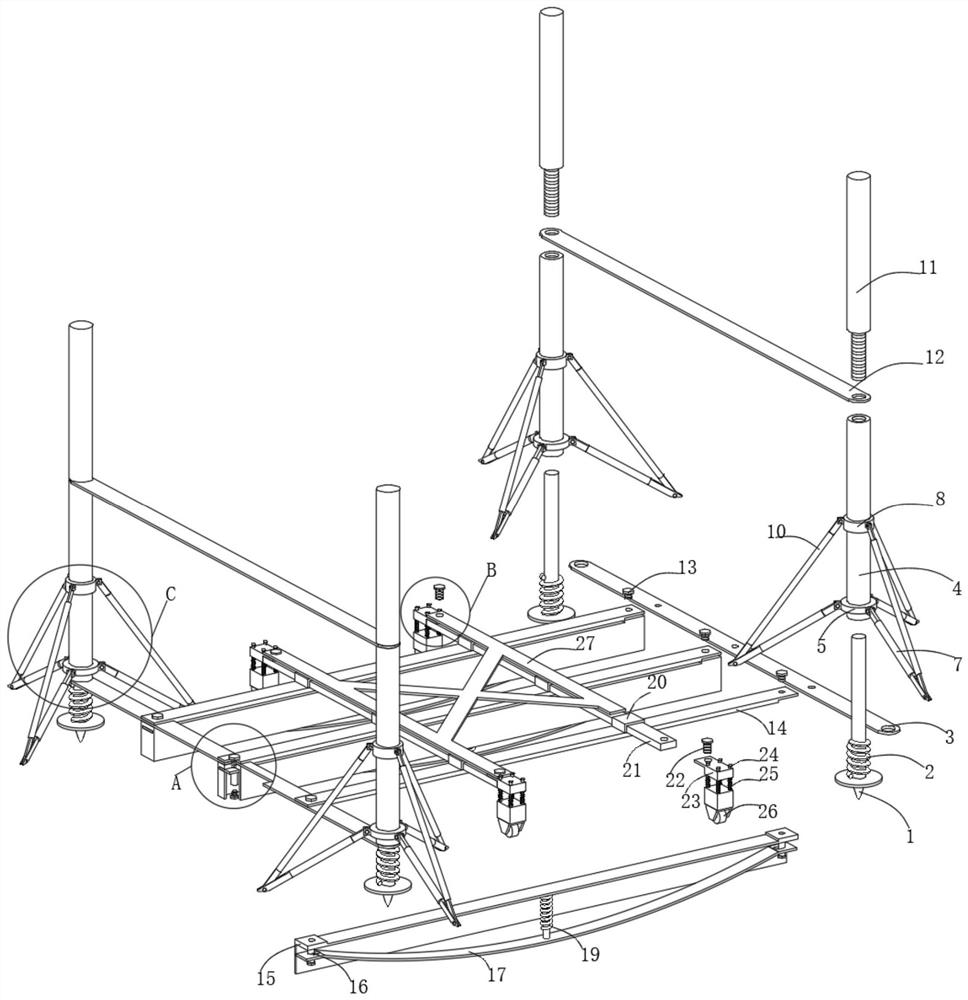

[0026] Embodiment one, with reference to Figure 1-6: A kind of anti-vibration support for civil construction machinery, including positioning bolt 1, the establishment of positioning bolt 1 provides the installation basis for other functional components of the equipment, and simultaneously enables the equipment to be installed and installed stably. There are four positioning bolts 1, each positioning The outer surface of the bolt 1 near the edge of the bottom end is evenly covered with a support ring. The establishment of the support ring can effectively carry out the stable support of the first support spring 2. The outer surface of each positioning bolt 1 is located above the corresponding support ring. One support spring 2, the establishment of the first support spring 2 can stably support the first limit plate 3, and at the same time, it can effectively make the equipment run weaker civil engineering machinery and the vertical vibration generated by the construction person...

Embodiment 2

[0027] Embodiment two, refer to Figure 1-3 with Figure 5 : the outer surface of each first support rod 7 is provided with a first connection hole near the edge of one end, the establishment of the first connection hole cooperates with the second connection hole to facilitate the installation of the connection block, and each second support rod 10 A second connection hole is opened on one side of the outer surface close to the edge of one end, and a connection block is slidably embedded between the interior of each second connection hole and the interior of the corresponding first connection hole. The establishment of the connection block can effectively carry out the first Fixation between the support rod 7 and one end of the second support rod 10, the top of each first support spring 2 is attached to the bottom of the corresponding first limit plate 3, and the bottom end of each first support spring 2 is attached to the top of the corresponding support ring. Together, thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com