Storage cabinet and tool recovery system

A recovery system and locker technology, applied in the field of robotics, can solve the problems of improving the efficiency of tableware recycling and unfavorable automation of tableware recycling, so as to achieve the effects of improving the degree of automation and recycling efficiency, reducing the degree of manual participation, and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

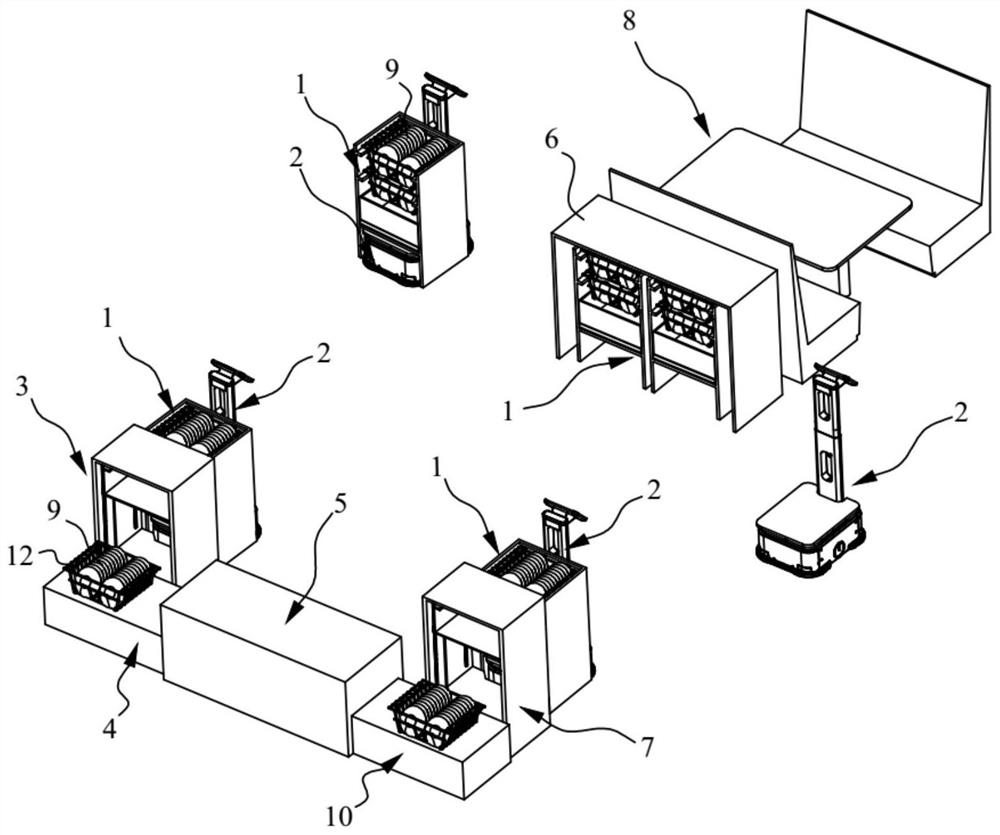

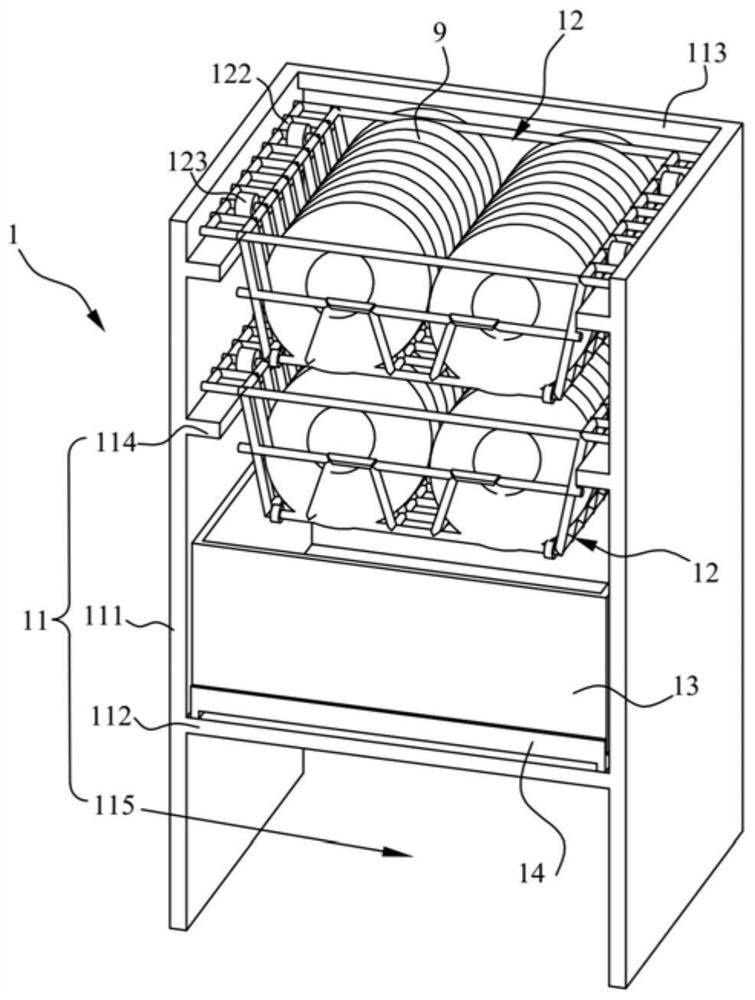

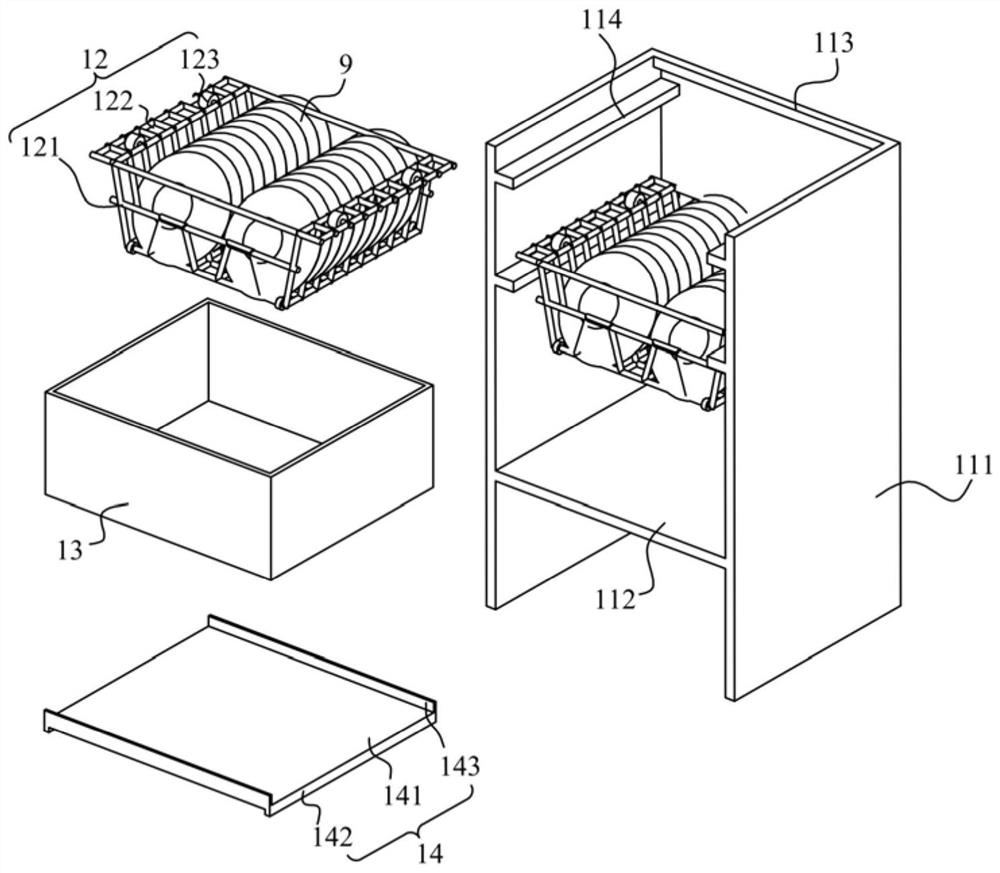

[0048] figure 1 The schematic structural diagram of the utensil recovery system provided by the embodiment of the present invention, such as figure 1 As shown, the present embodiment provides a utensil recovery system, which can be applied to dining places such as canteens, restaurants or hotels, and is used to automatically recover and clean utensils 9 after meals, so as to improve the automation degree of utensils 9 recovery and the recovery of utensils. Recycling efficiency reduces the labor cost required for the recycling of utensils 9 .

[0049]Specifically, the appliance recycling system provided in this embodiment includes a transport robot 2 and a locker 1 that can be placed independently. The locker 1 is provided with an appliance accommodating space. The transport robot is used to move the locker 1, and the locker 1 can The storage state of the utensils in the storage space sends a recovery and delivery command to the transport robot 2, so that the transport robot 2...

Embodiment 2

[0118] Figure 10 The flowchart of the utensil recycling method provided by the embodiment of the present invention, such as Figure 10 As shown, this embodiment provides a method for recovering utensils, which is applied to the utensils recovery system in the first embodiment, and is used for automatic recovery operation of utensils 9, so as to improve the recovery efficiency of utensils 9 and reduce the cost of recovering utensils 9. Labor costs are required.

[0119] Such as Figure 10 As shown, the utensil recovery method includes the following steps:

[0120] Step S1, the delivery robot 2 waits at the waiting point;

[0121] Step S100, judging whether the delivery robot 2 has received an appliance recovery instruction, if yes, execute step S101, if not, execute step S200;

[0122]The person who sends the utensil recovery instruction to the delivery robot 2 can be a restaurant staff or a customer who has a meal. Restaurant staff or customers can send utensil recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com