Automatic clamping intelligent welding equipment for buffer seat of mining cage supporting device

A buffer seat and support tank technology, which is applied to welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low work efficiency, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

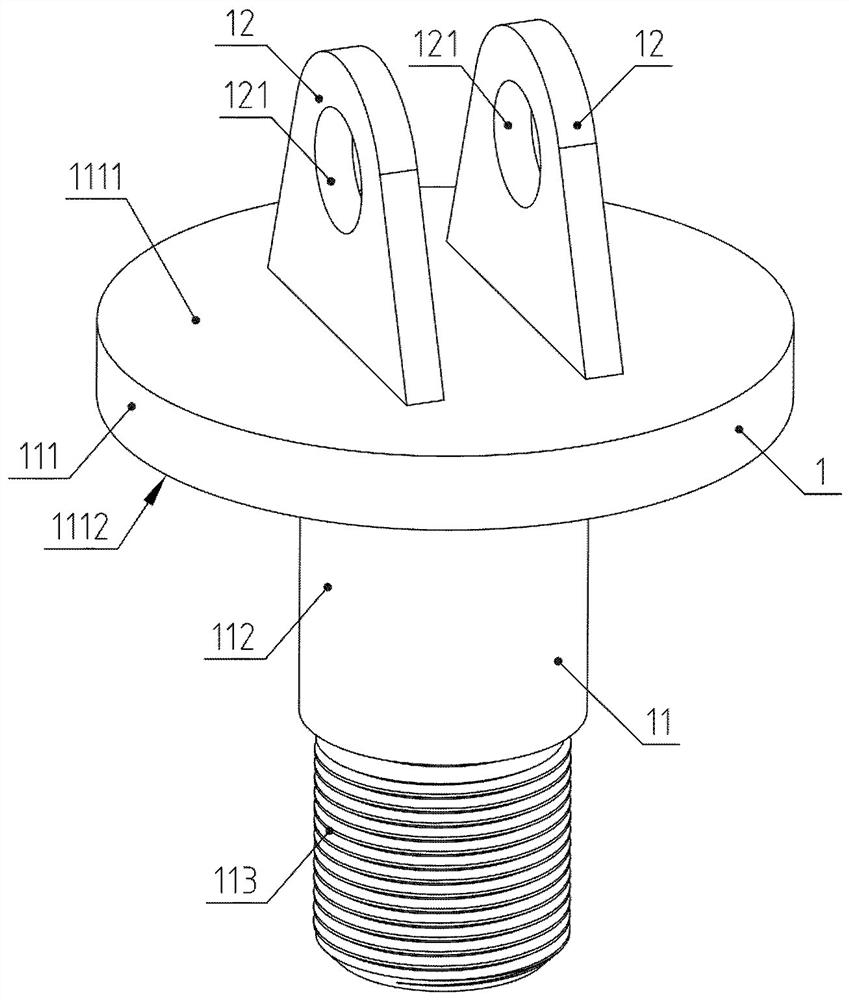

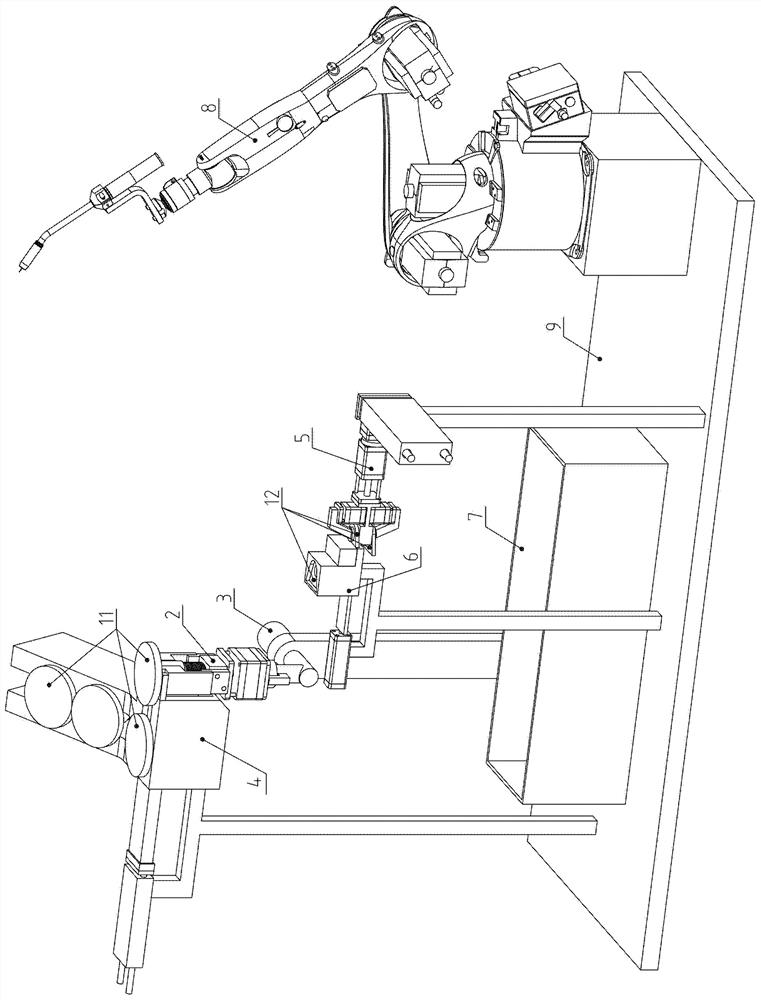

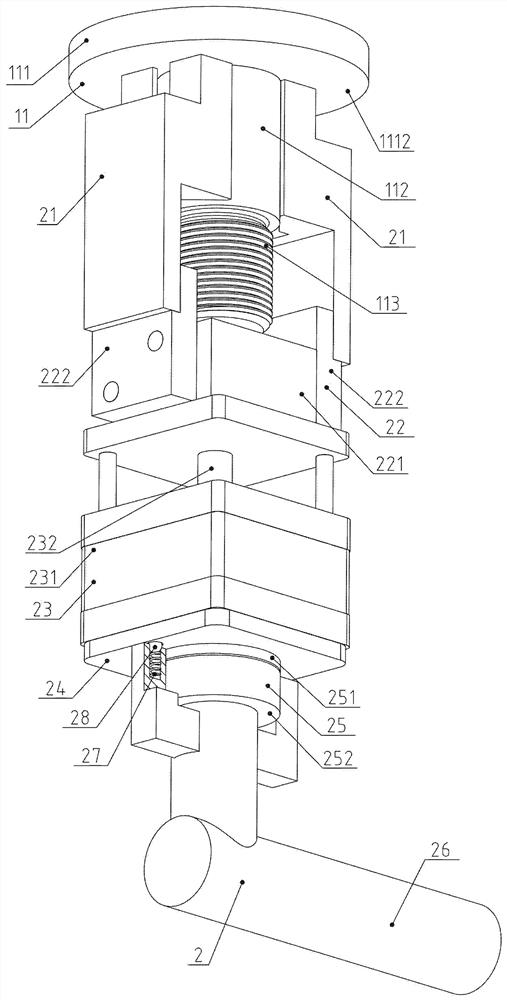

[0087] Example: see Figure 1 to Figure 11 .

[0088] A kind of automatic clamping intelligent welding equipment for the buffer seat of the mine support tank device, comprising a guide manipulator 2, a guide servo motor 3, a guide feeder 4, an intelligent welding robot 8 and a frame 9; an intelligent welding robot 8 and Frame 9 is fixedly connected;

[0089] The guide manipulator 2 includes a guide reversing frame 26; the guide reversing frame 26 includes a guide reversing shaft 261; the guide reversing shaft 261 and the frame 9 are connected by a revolving pair; the housing of the guide servo motor 3 passes through the flange and the frame 9 fixedly connected; the output shaft of the guide piece servo motor 3 is fixedly connected with the guide piece overturning shaft 261; the guide piece servo motor 3 drives the guide piece manipulator 2 to turn over; the axis line of the guide piece overturning shaft 261 is arranged along the left and right horizontal directions;

[0090] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com