Multifunctional reverse scraper perforating device

A technology of punching device and reverse scraper, which can be used in boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., which can solve the problems of wasting time and many processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

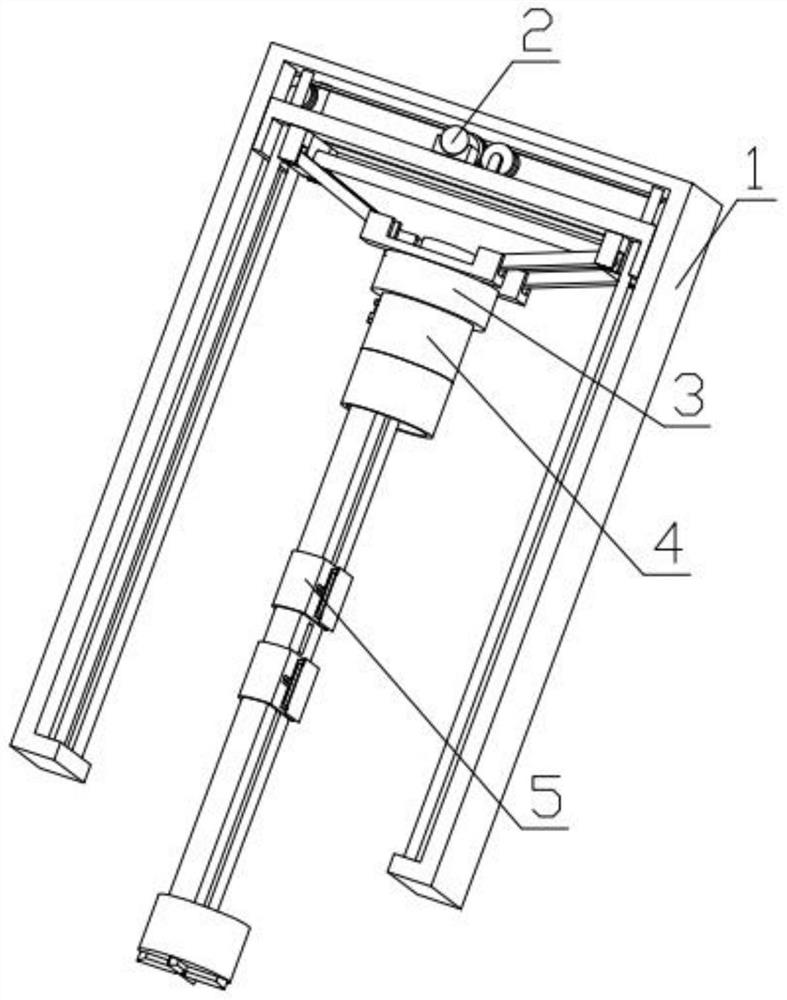

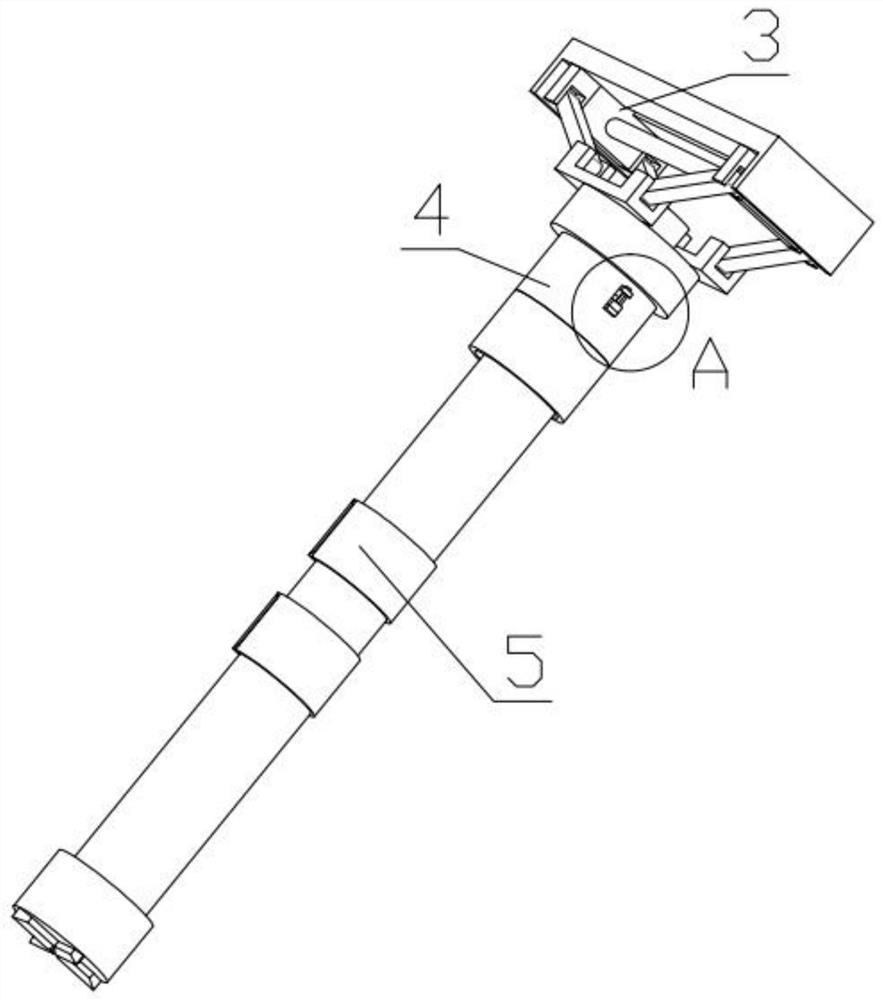

[0034] Combine below Figure 1-13Describe this embodiment, a multifunctional anti-scraper punching device, including a rail frame 1, a propulsion mechanism 2, a fine-tuning mechanism 3, a punching mechanism 4 and a two-way anti-scraper mechanism 5, and the propulsion mechanism 2 is fixedly installed on the fine-tuning mechanism 3. The fine-tuning mechanism 3 is slidably installed on the track frame 1, the propulsion mechanism 2 is engaged with the track frame 1, the punching mechanism 4 is fixedly installed on the fine-tuning mechanism 3, and the two-way anti-scraper mechanism 5 is fixedly mounted on the punching mechanism 4.

specific Embodiment approach 2

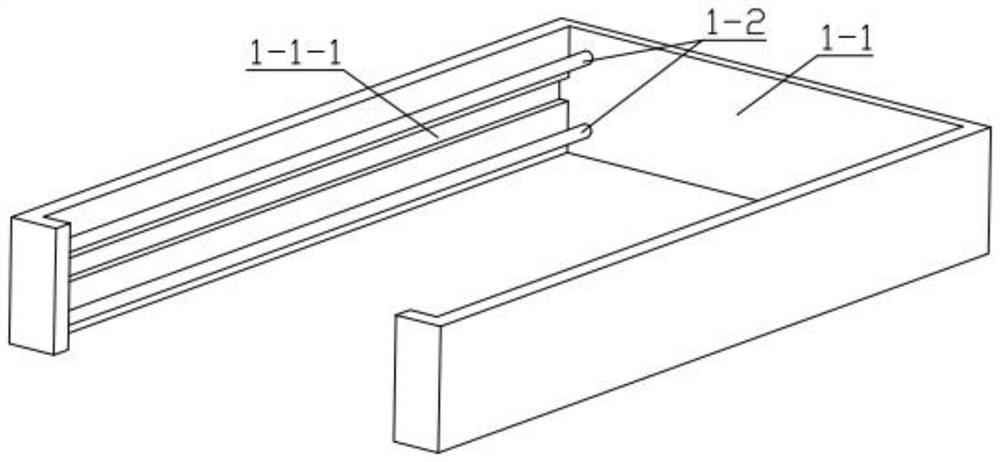

[0036] Combine below Figure 1-13 Illustrate this embodiment, and this embodiment will further explain Embodiment 1. The track frame 1 includes a U-shaped frame 1-1 and a track bar 1-2. The track bar 1-2 is fixedly installed with two parts of the U-shaped frame 1-1. side.

specific Embodiment approach 3

[0038] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 2, the described propulsion mechanism 2 includes a moving sprocket 2-1, a chain 2-2, a guide sprocket 2-3, and a main sprocket 2-4 , chain two 2-5, moving sprocket two 2-6, displacement motor 2-7, moving sprocket one 2-1, guide sprocket 2-3, main sprocket 2-4 and moving sprocket two 2-6 Fixedly installed on the fine-tuning mechanism 3 respectively, the moving sprocket 2-1 meshes with the chain 2-2, the chain 2-2 meshes with the guide sprocket 2-3, and the guide sprocket 2-3 meshes with the main sprocket 2-4 phase meshing, the main sprocket 2-4 is fixedly installed on the output end of the displacement motor 2-7, the displacement motor 2-7 is fixedly installed on the fine-tuning mechanism 3, the main sprocket 2-4 is in phase with the chain 2-5 Engagement, chain two 2-5 meshes with mobile sprocket two 2-6, mobile sprocket one 2-1 meshes with tooth groove 1-1-1 provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com