Improved steel coil decoiler capable of improving leveling precision

A leveling machine and precision technology, which is applied in the field of steel plate processing, can solve the problems affecting the leveling accuracy of steel coils, affecting the leveling effect, and the tension of steel coils, so as to achieve the effects of improving work efficiency, good leveling effect, and accurate flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

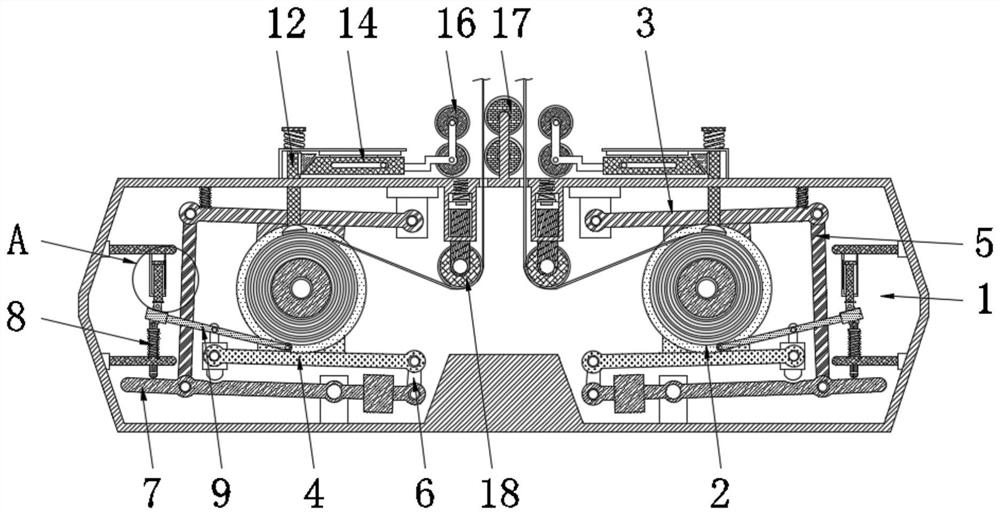

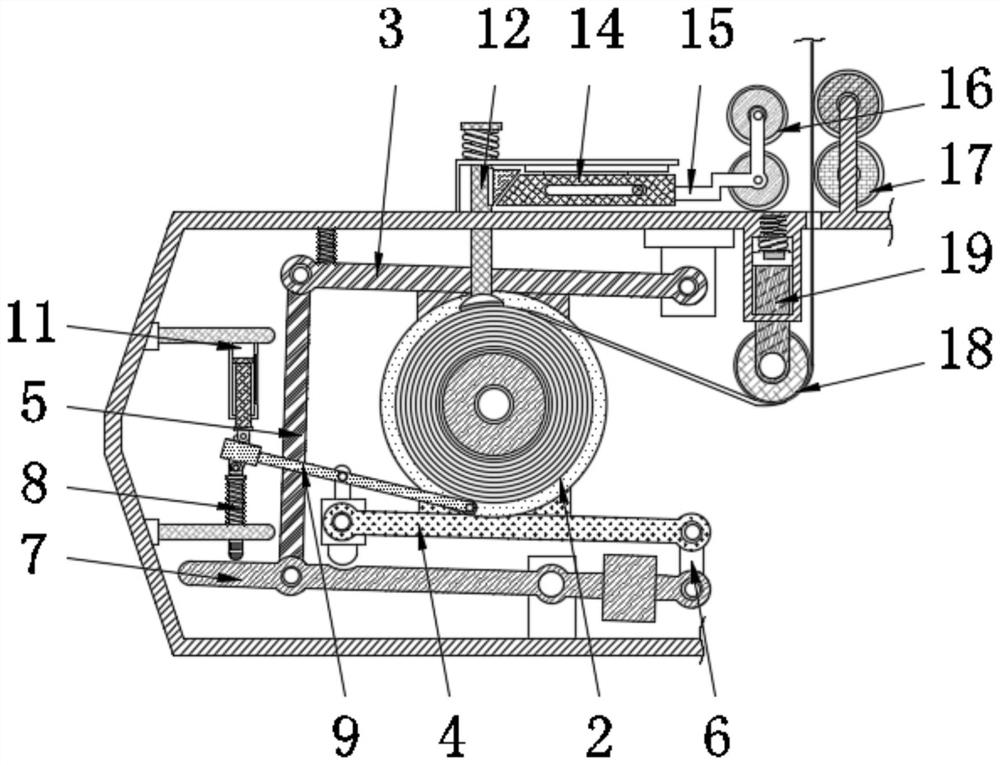

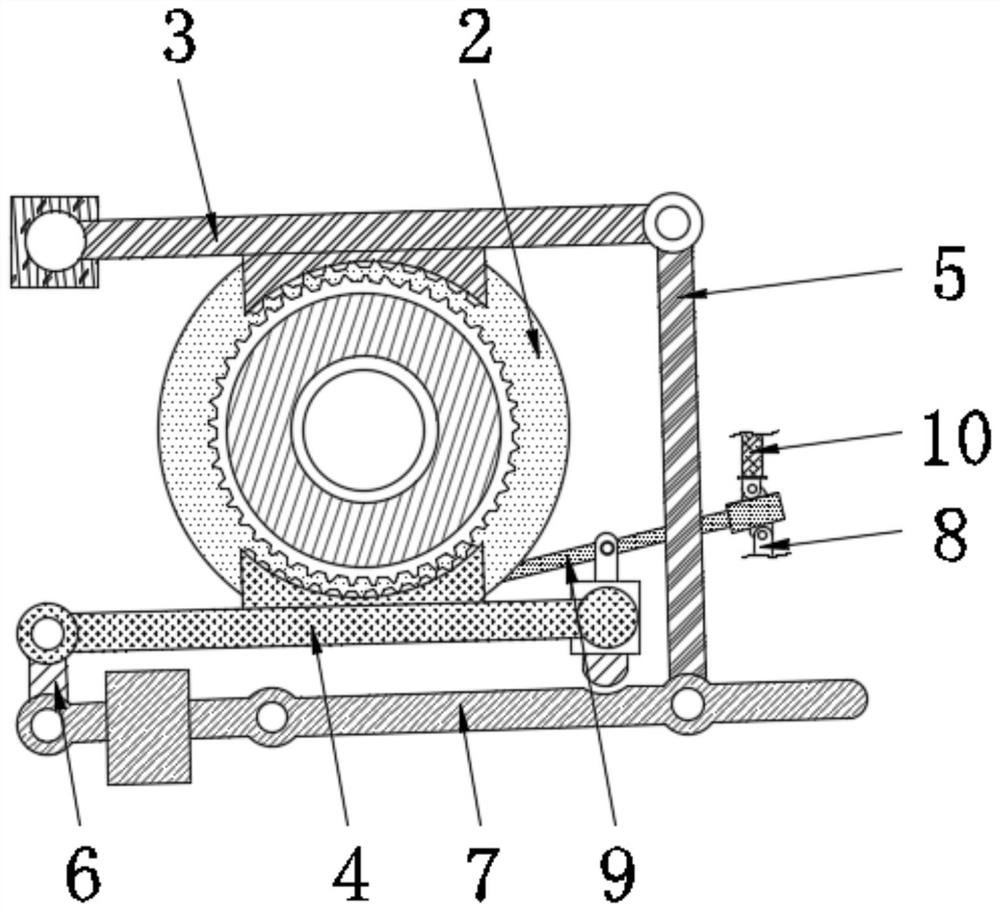

[0022] The invention provides an improved steel coil leveling machine with improved leveling precision, as shown in the attached figure 1 To attach Figure 5 Shown: including the engine compartment 1, the interior of the engine compartment 1 is equipped with a steel coil seat 2, and the upper and lower sides of the rear surface of the steel coil seat 2 are provided with corresponding upper splints 3 and lower splints 4, and the upper splint 3 and the lower splint The opposite surface of the splint 4 and the rear surface of the steel coil seat 2 are provided with corresponding tooth blocks, the left end of the upper splint 3 is movably connected with the adjusting rod 5, and the right end of the lower splint 4 is movably connected with the connecting rod 6, and the adjusting rod 5 and The connecting rods 6 are respectively movably installed on the inside and the right end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com