Steam cleaning machine for false tooth processing

A washing machine and steam technology, which is applied in the direction of dryers, progressive dryers, lighting and heating equipment, etc., can solve the problems of labor-consuming, low efficiency, and damage to the bonding force, so as to facilitate subsequent packaging and high work efficiency , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

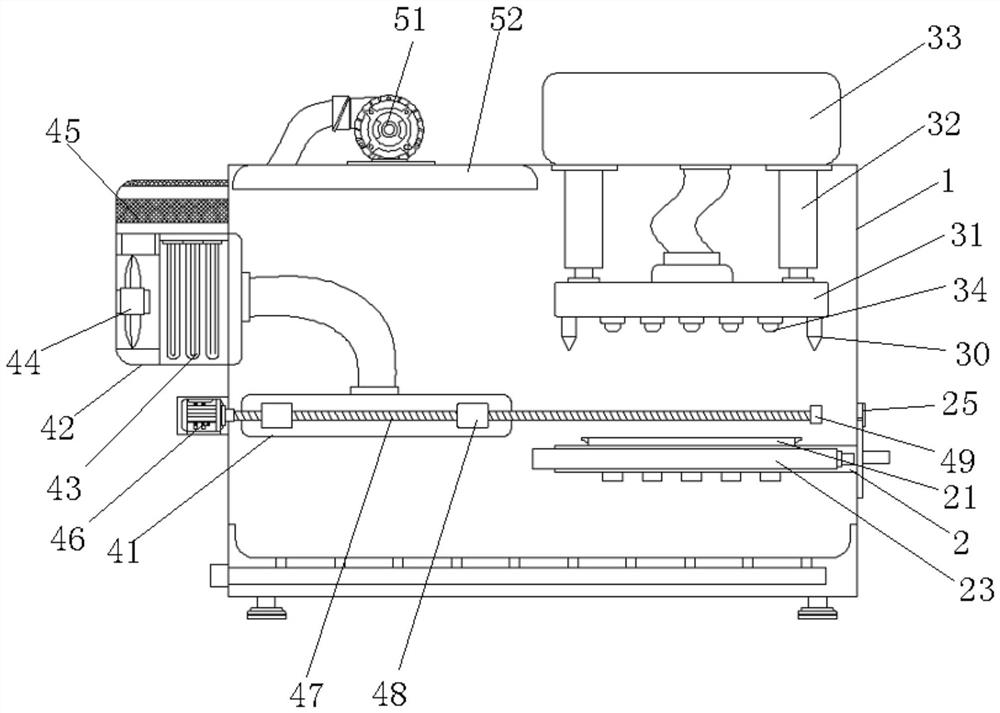

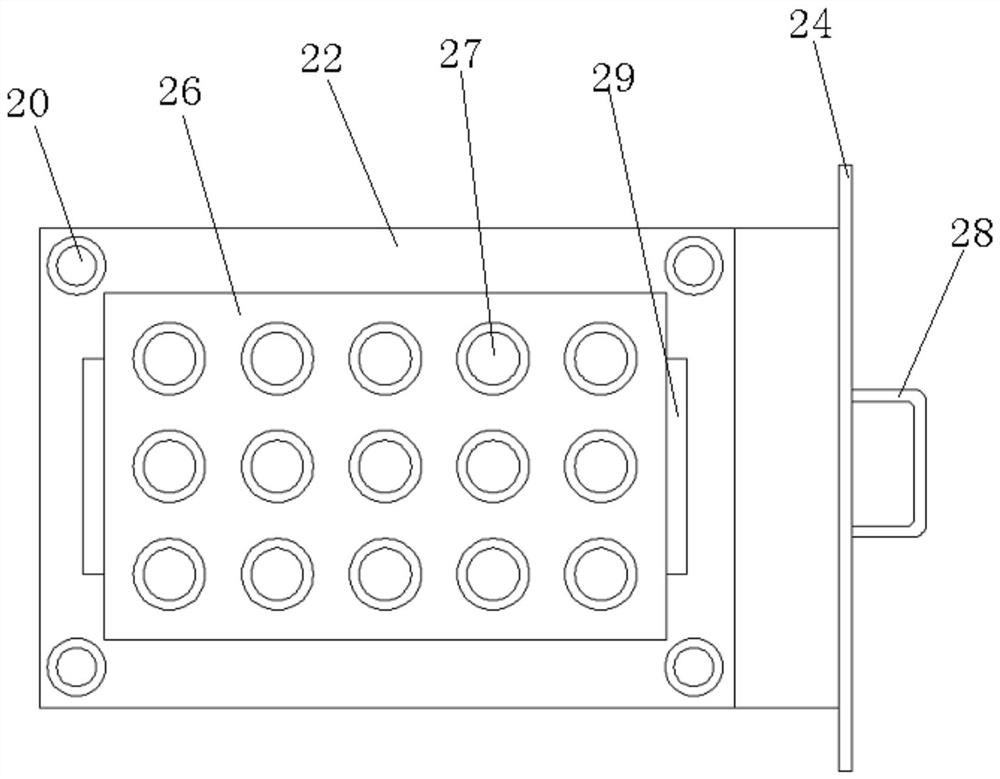

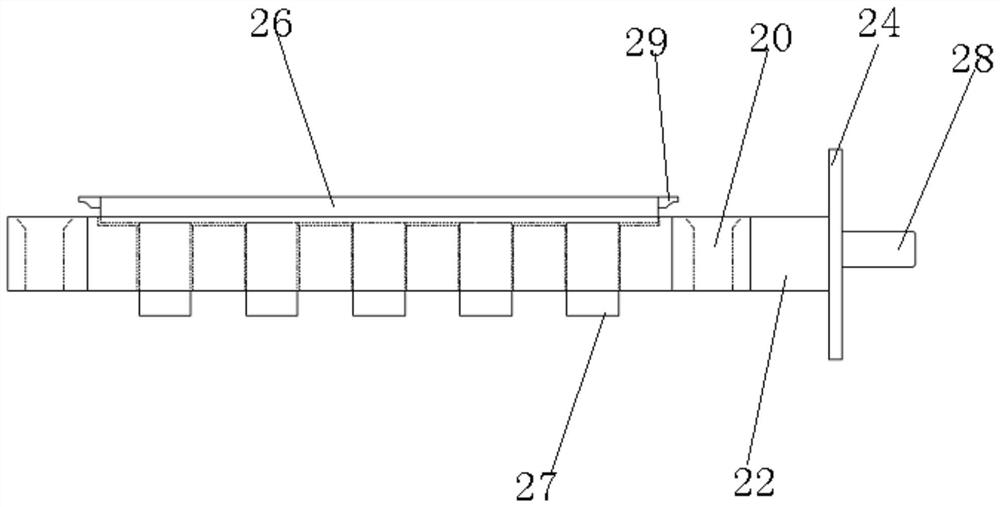

[0021] Such as Figure 1~4 as shown,

[0022] This embodiment provides a denture processing steam cleaning machine, including a body 1 and a cleaning tray 2 arranged in the body 1, a steam device, a drying device and an exhaust device, and also includes a storage tray detachably installed on the cleaning tray 2 21. The storage tray 21 is used to store the dentures to be cleaned. The cleaning tray 2 is a drawer-type structure. The body 1 is provided with a pull-out cavity corresponding to the cleaning tray 2. The steam device is installed on the upper end of the cleaning tray 2; The tray 2 includes a template 22 and drawer slide rails 23 arranged at both ends of the template 22. The side of the drawer slide rail 23 away from the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com